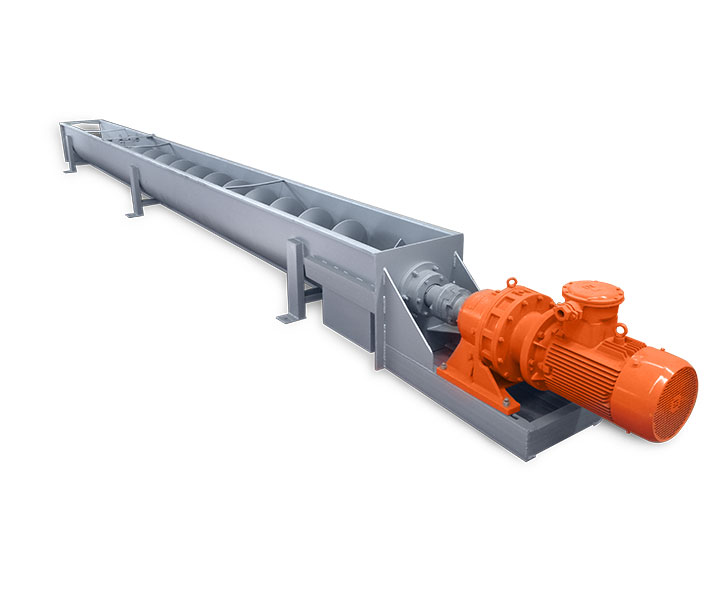

Continuous conveying equipment for conveying powdery, granular and dry bulk materials

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

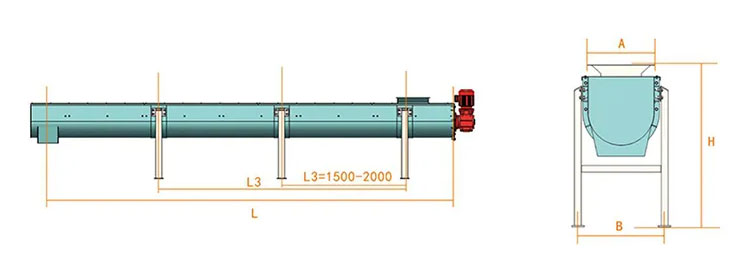

Length: 10-20 meters

Output: 134 cubic / hour

U-groove width: 200mm, 250mm, 300mm, 400mm, 500mm, 600mm

Weight: 726-7090kg

Speed: 13-75r/min

Customization: material (carbon steel or stainless steel), screw shaft (with/without shaft, single shaft/double shaft), import and export distance, feed port size, etc. (customized on demand)

application:Industries such as pet food, plastic processing, soap, washing powder and detergent processing, animal feed processing, wood processing, chemicals, environmental technology, cement, lime and gypsum processing, and mining.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

U-type screw conveyor has a U-shaped trough or channel instead of a cylindrical trough. The U-type design provides a larger carrying capacity than a standard cylindrical trough, making it suitable for handling larger volumes of material.

U-type screw conveyors are commonly used in a wide variety of industries, including agriculture, food processing, chemical processing, and wastewater treatment. They are effective for transporting powders, granules, pellets, and other bulk materials over both short and long distances.

1. According to the structure:

U-type Shaftless Screw Conveyor: granular/powder materials, wet/paste materials, semi-fluid/viscous materials, easily entangled/easy to block materials, materials with special hygienic requirements.

U-type Shafted Screw Conveyor: materials that are not easy to stick, and have certain friction. There are certain requirements for the wear resistance of the screw conveyor.

2. According to the material:

Carbon steel U-type screw conveyor: mainly used in cement, coal, stones and other industries with high wear and no special requirements for sanitation.

Stainless steel U-type screw conveyor: It is mainly used in food, grain, chemical and other industries that have requirements on the conveying environment. It has a high degree of cleanliness and will not pollute materials.

U-type screw conveyor is suitable for conveying powder, granular and small block materials with small inclination and small range. It is widely used in food, chemical, building materials, metallurgy, mining, electric power and other departments. The following are several common applications occasion:

Sewage treatment plant: It can be used in sewage treatment plant to transport solid debris, such as coarse and fine grid cleaning machine slag and sludge cake of sludge dewatering machine.

Waste treatment plant: kitchen waste or domestic waste generated by household kitchens, restaurants, restaurants, canteens, markets and other industries, stainless steel material can prevent damage to the machine due to corrosive materials.

Industrial waste treatment: such as boiler coal loading system, solid waste incineration, etc.

Cement batching plant: It is used for conveying powder materials such as cement and fly ash. During the conveying process, it can also realize the purpose of mixing and stirring the materials to prevent the concrete from agglomerating.

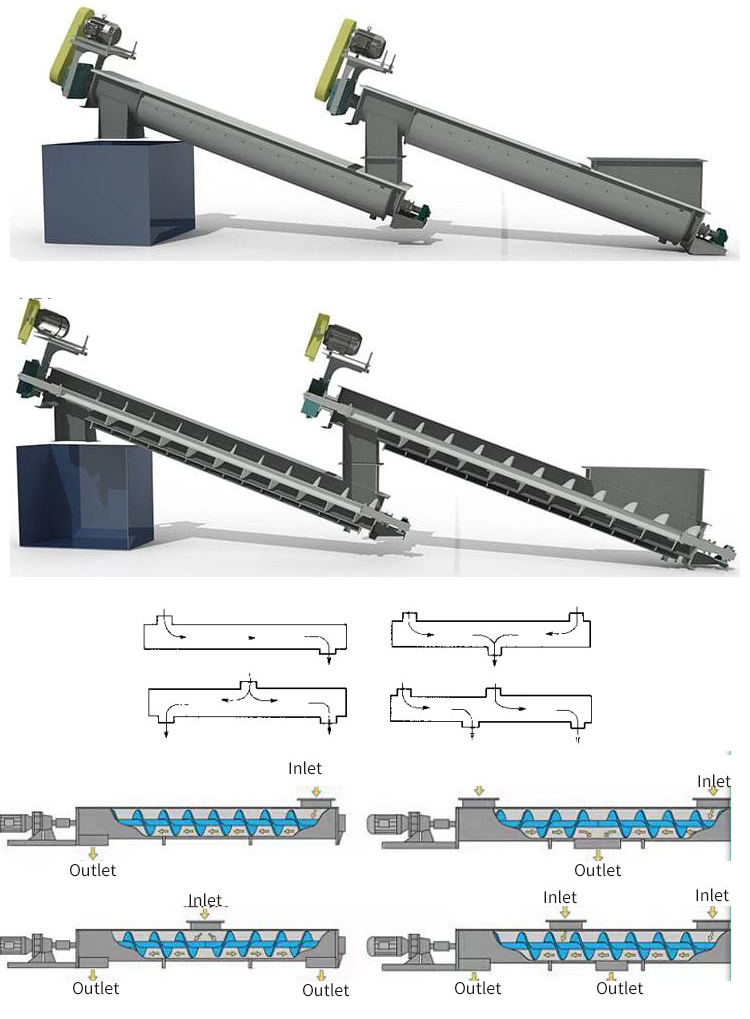

U-type screw conveyors work by using helical helical blades or augers that rotate within a U-shaped trough to move bulk material along the length of the conveyor.

Detailed conveying process: put the bulk material to be conveyed into the U-type groove at the inlet end of the conveyor, and the helical blade or auger rotates in the U-type groove to make the material move along the length of the conveyor. With the rotation of the helical blade, it Make the material move forward along the length of the U-shaped trough, and transport the material from the inlet end of the conveyor to the discharge end. At the discharge end of the conveyor, the material is discharged from the U-shaped trough and enters the downstream process.

The rotation of the helical blades within the U-type trough creates a positive displacement action that moves the material along the length of the conveyor. The precise speed and rate of delivery can be controlled by adjusting the rotation speed of the helical blade and the angle of the U-shaped groove.

Large carrying capacity

The U-shaped trough design has a greater load-carrying capacity than standard cylindrical troughs and can transport larger volumes of material.

Handle materials gently

The helical blades within the U-shaped trough gently move the material, minimizing the risk of damage or degradation during transport, which is important for fragile or easily damaged materials.

Minimum material accumulation

The U-shaped trough design is easy to clean and maintain with minimal material buildup. This reduces the risk of material contamination and ensures long-term stable performance.

Flexible design

Can be customized to suit a wide range of applications, with customizable lengths, widths, angles and other features. This makes them suitable for a variety of industries including agriculture, food processing and chemical processing.

Easy to maintain

The discharge door, hopper and cover can be adjusted to facilitate timely observation of the conveying situation and easy maintenance of the machine at any time.

Run efficiently

Can be designed for high capacity operation with low power requirements. This makes them energy efficient and cost effective.

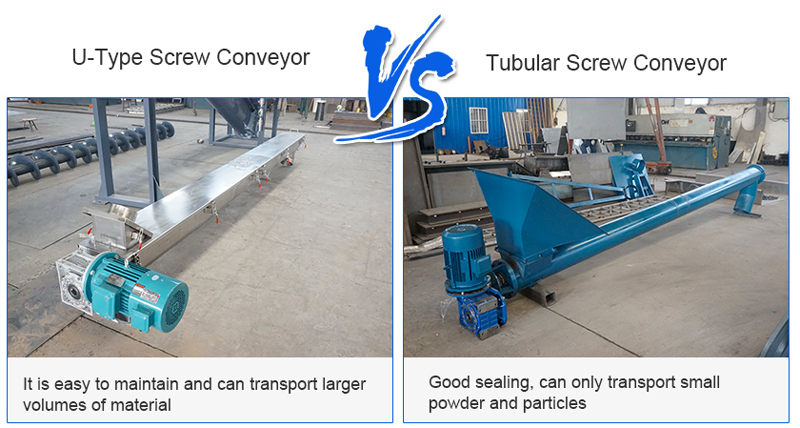

Both U-stype screw conveyors and tubular screw conveyors are commonly used in industry to convey bulk materials, but there are some differences between the two that may make one conveyor more suitable than the other depending on specific application requirements. Here are some key differences:

| Comparison item | U-Type Screw Conveyor | Tubular Screw Conveyor |

| Material handling | Better for handling fragile or easily damaged materials as the helical blades in the U-shaped trough gently move the material. | Better suited for handling abrasive materials as the material moves along the inside of the tube which helps protect the screw blades from wear. |

| Carrying capacity | It is suitable for conveying bulky products and has a greater carrying capacity than tubular screw conveyors. | The conveying capacity is smaller than U-type screw conveyor. |

| Maintenance | Easier to clean and maintain as the U-slot design provides easy access to the auger blades and minimizes material buildup. | Can be more difficult to clean as material may become trapped inside the tube. |

| Cost | Typically more expensive than tubular screw conveyors due to greater load capacity and more complex design. | Lower cost |

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

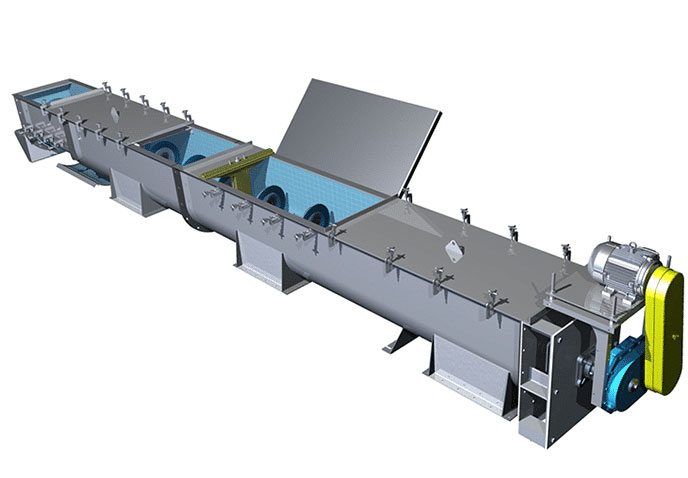

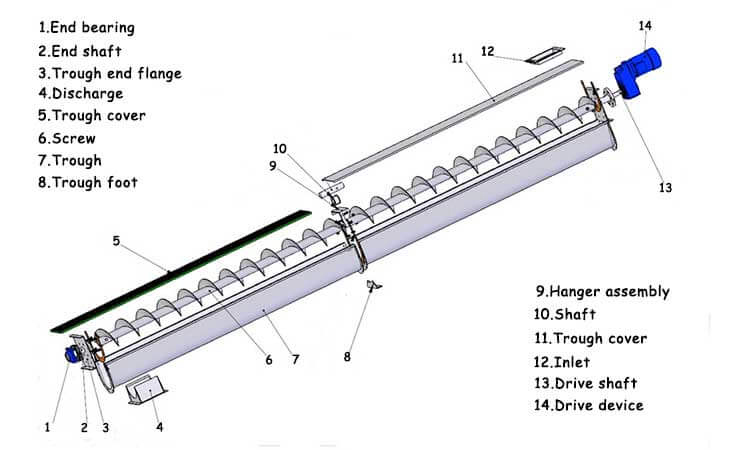

U-type screw conveyor drive device, coupling, screw shaft, tank body, hanging bearing device, bearing device at both ends, support, cover, inlet and outlet, etc.

1. Driving device: Cycloidal pinwheel reducer or shaft-mounted hard-tooth surface gear reducer is used. In the design, the driving device should be set at the end of the discharge port as much as possible, so that the screw body is in a tension state during operation.

2. The head is equipped with a thrust bearing, which can bear the axial force generated when conveying materials.

3. Spiral blade: the general material is stainless steel or carbon steel. Considering the service life, it is recommended to use spiral conveyor blades made of high-strength wear-resistant steel.

4. Chassis: It is a "U"-shaped groove, with a rain-proof cover on the upper part, and the material is stainless steel or carbon steel or glass fiber reinforced plastic.

5. Tank body lining board: It is made of high-strength engineering plastic polymer polyethylene, which has weak adsorption, non-stick material, wear resistance and corrosion resistance.

6. Inlet and outlet: There are two kinds of square and round. Generally, the form of inlet and outlet is determined by the user.

U-type screw conveyors can be customized with various options and features to meet the specific requirements of different applications. Here are some of the most common options:

Material of construction: The U-shaped trough and screw blade can be made of a variety of materials, including stainless steel, carbon steel, and other specialty alloys. The choice of material will depend on the characteristics of the material being transported and the operating conditions of the application.

Surface finish: The surface of the U-shaped trough and screw blade can be finished in a variety of ways to prevent material buildup and to meet hygiene standards. Options include polished, painted, and coated finishes.

Shaft seal: U-type screw conveyors can be designed with various types of shaft seals to prevent material from leaking out of the conveyor. Options include packing seals, mechanical seals, and gland packing.

Discharge gate: The discharge end of the U-shaped trough can be fitted with various types of gates to control the flow of material out of the conveyor. Options include slide gates, flap valves, and rotary valves.

Hopper: A hopper can be added to the inlet end of the U-shaped trough to provide a buffer and to facilitate loading of the material into the conveyor.

Covers: Covers can be added to the U-shaped trough to protect the material from contamination and to prevent spills.

Heating or cooling jacket: The U-shaped trough can be jacketed with a heating or cooling medium to regulate the temperature of the material during transport.

Our customers need to transport pulverized coal from one plant to another while maintaining the quality and dryness of the pulverized coal. We designed a U-shaped screw conveyor for this customer, and selected stainless steel materials according to the customer's requirements. We have also installed dust covers and dust removal devices at the entrance and exit of the conveyor to ensure the surrounding environment is clean and safe. In the end, installation and commissioning were carried out at the customer's site, and a stable and reliable U-shaped screw conveyor was delivered to meet the customer's needs. Customers are very satisfied with our professional technology and high-quality service, and have more confidence in our UNIVERSAL brand.

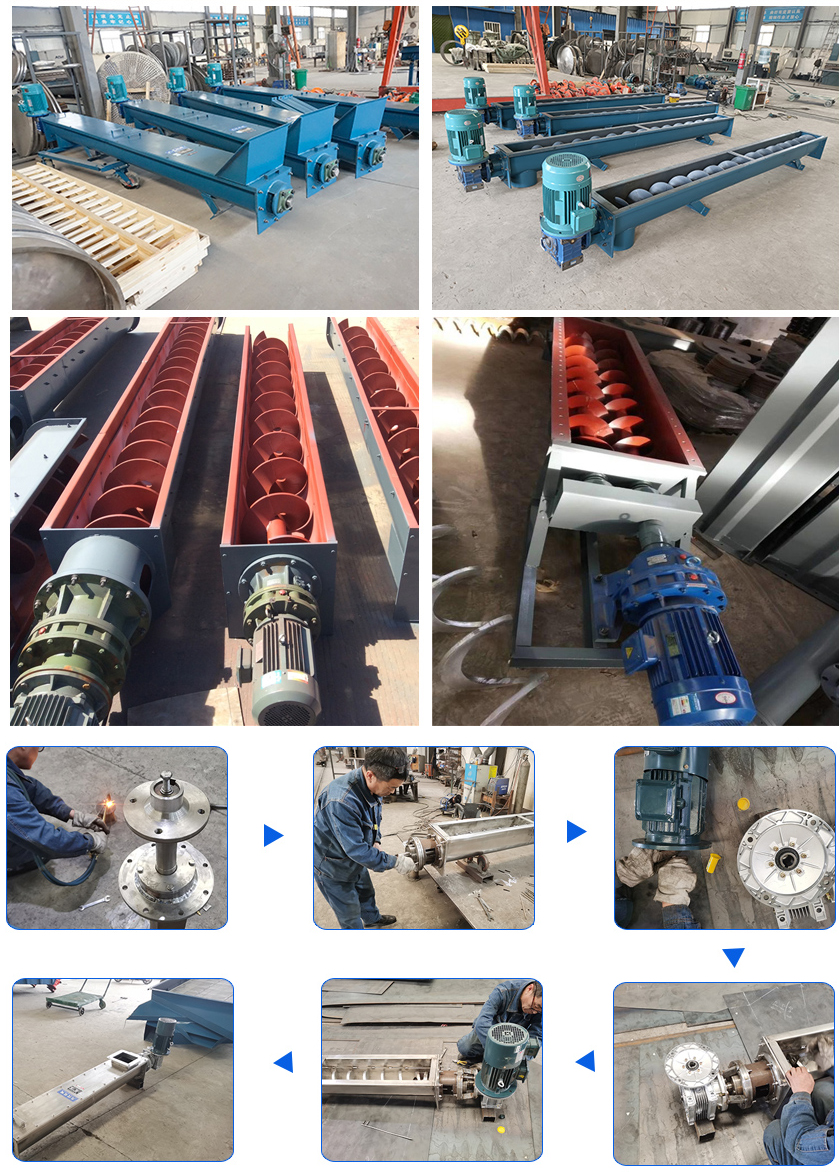

Xinxiang Dahan has 15 years of experience in producing U-type screw conveyors. The screw conveyors have a complete range of models and can provide free selection and drawing design. It has various lathes, milling machines, installation workshops, spraying workshops, warehouses and other processing workshops All kinds of cutting machine, bending machine, polishing machine processing equipment, provide one-stop service from design, drawing, processing, assembly, painting, quality inspection, test machine, packaging and delivery, provide 12-month quality warranty, and provide life-long repair service.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.