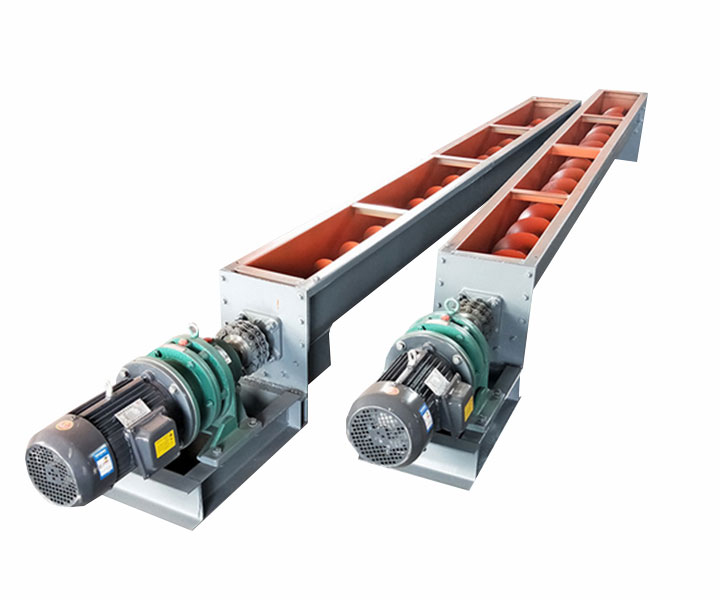

For horizontal or slightly elevated mechanical conveying of powdery, granular and lumpy bulk materials in the food, grain and non-food industries

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Conveying length: 10-20 meters

Delivery capacity: 9-134m³/h

Tilt angle: horizontal or tilted below 20 degrees

Customization: material (carbon steel or stainless steel), screw shaft (with/without shaft, single shaft/double shaft), import and export distance, feed port size, etc. (customized on demand)

Applications: Widely used in pet food, plastic processing, soap, washing powder and detergent processing, animal feed processing, wood processing, chemical industry, environmental technology, cement, lime and gypsum processing, and mining industries all over the world.

Commitment:

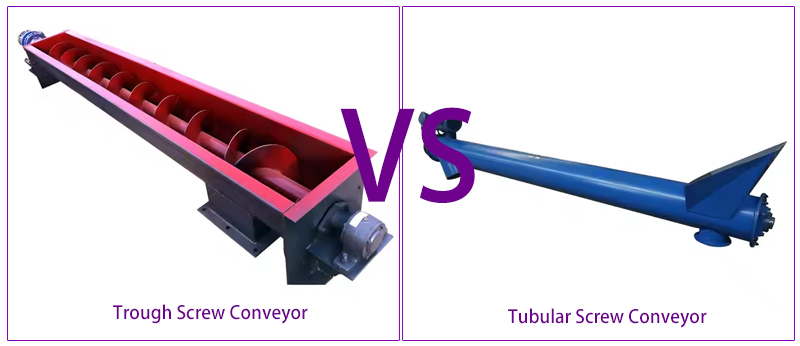

Trough screw conveyors are designed with U-shaped troughs, which are the most common trough shape and are suitable for almost all applications. Remove cover for full access to screws and hangers; makes screw conveyors less maintenance-intensive for horizontal or slightly elevated mechanical conveying of powders, granules and lumps in the food, grain and non-food industries bulk material. With proper design, trough screw conveyors can also be used for batching, wetting, mixing or crushing of bulk materials.

The trough design of the trough screw conveyor can effectively guide and constrain the conveyed material, ensure that the material moves correctly along the spiral blades of the screw conveyor, and prevent blockage and leakage. Different types of trough designs can adapt to the conveying of materials of different types and properties, ensuring a stable and efficient conveying process.

Classification by driving method

Single shaft trough screw conveyor: When the length of the trough screw conveyor is less than 35m, it is a single-axis driven screw.

Double shaft trough screw conveyor: When the length of the trough screw conveyor is greater than 35m, it is a double-shaft driven screw.

Classification by type of intermediate hanging bearings

Rolling hanging shaft trough screw conveyor: Rolling crane bearing adopts 80000 type sealed bearing, which is commonly used to transport materials with a temperature of ≤80°C.

Sliding hanging shaft trough screw conveyor: Sliding crane bearings are equipped with dust-proof sealing devices and are often used to transport materials with relatively high temperatures ≥80°C or materials with large moisture content.

Classification by screw conveyor material

Carbon steel trough screw conveyor: Ordinary carbon steel is mainly suitable for cement, coal, stone, and other industries that have no special requirements for materials.

Stainless steel trough screw conveyor: Stainless steel material is mainly suitable for grain, chemical, food and other industries that have requirements for transportation environment. It has high cleanliness and no pollution, but the cost is high.

Trough screw conveyors are used in a wide range of industries and applications to move bulk materials horizontally or at a slight incline. Some of the common applications of trough screw conveyors include:

1. Agriculture:Are used to move grains, seeds, and other agricultural products from storage to processing or packaging facilities.

2. Chemicals: Are used to transport chemicals, such as powders, pellets, and granules, from one process to another.

3. Food and Beverage: Used to move food products, such as flour, sugar, and spices, from storage to processing or packaging facilities. They are also used to transport beverages, such as beer and soft drinks, from one process to another.

4. Mining: Used to transport ores, minerals, and other mining products from one location to another.

5. Pharmaceuticals:Used to move pharmaceutical powders, tablets, and capsules from production to packaging facilities.

6. Waste Management: Trough screw conveyors are used to move waste materials, such as municipal solid waste, from collection points to processing or disposal facilities.

7. Water Treatment: Used to move sludge and other waste materials from water treatment facilities to processing or disposal facilities.

8. Plastics: Trough screw conveyors are used to move plastic pellets, powders, and granules from production to packagingfacilities.

9. Construction: Used to transport construction materials, such as sand, gravel, and cement, from one location to another.

10. Recycling: Are used to move recyclable materials, such as paper, plastic, and metal, from collection points to processing facilities.

U trough screw conveyor

Trough loading screw conveyor

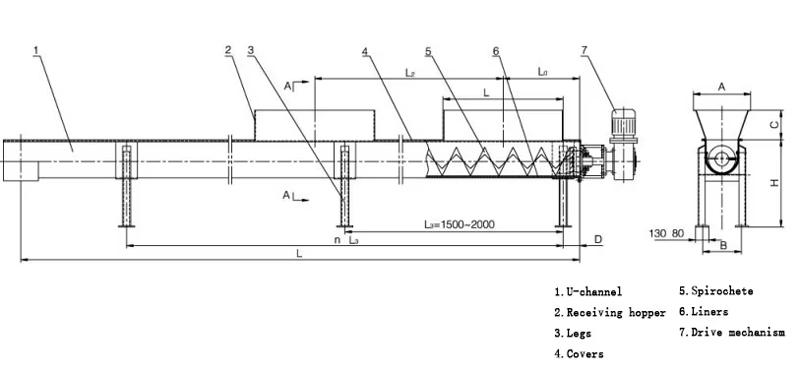

Trough screw conveyor is to use the thrust generated by the rotating spiral blade to transport the material to be conveyed. It is usually composed of three parts: the screw conveyor body, the in and out device, and the driving device. The material enters from the feed port of the screw conveyor, and moves in the direction of the discharge port under the rotation of the spiral blade.

Versatility

Can handle a wide range of materials, including powders, granules, and pastes. They can also be used for both dry and wet materials, making them a versatile option for many applications.

Minimal Maintenance

When disassembling the screw, there is no need to move the drive device, and when disassembling the suspension bearing, there is no need to move the screw. The suspension bearing can be lubricated without removing the cover plate.

Customizable

Can be customized to fit specific applications. They can be designed to handle specific materials, operate at specific speeds, and fit into specific spaces.

Hygienic

Can be designed to meet hygienic standards for food and pharmaceutical applications. They can be constructed from materials that are easy to clean and sanitize, such as stainless steel.

Space-Saving

It has a compact design and can be installed in tight spaces and can be configured to fit into existing processing lines.

Gentle Handling

Provide a gentle handling of the materials being transported, which is particularly important for fragile materials or those that are easily damaged.

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

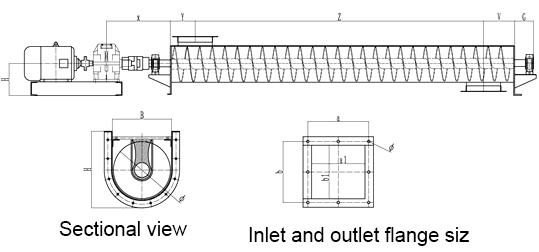

A trough screw conveyor is a mechanical device used to transport bulk materials, such as powders, granules, and small pieces of solid matter. It consists of several key components:

Trough: This is the main housing of the conveyor, typically made of metal (often steel) and shaped like a U or V. It encloses the screw and provides a channel for the material to travel.

Screw: This is the rotating element of the conveyor. It consists of a shaft with helical blades (flights) attached to it. The screw's rotation propels the material along the trough.

Drive Unit: This is the motor that powers the screw's rotation. It can be located at either end of the conveyor or in the middle.

Bearings: These support the shaft and allow it to rotate smoothly. They are typically located at each end of the screw and may also be placed at intervals along the length of the conveyor for longer units.

Inlet and Outlet: These are openings in the trough where material enters and exits the conveyor.

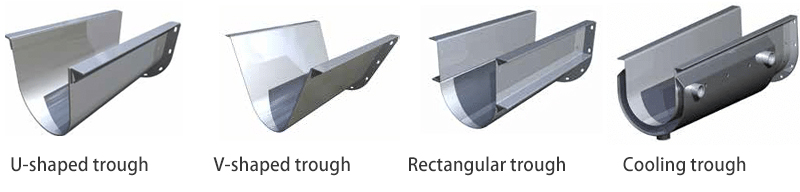

Trough screw conveyor troughs come in a variety of shapes and sizes to accommodate different materials and applications. Here are some common types:

1. U-shaped trough: The most common type, offers a good balance between material containment and ease of cleaning, suitable for a wide range of materials.

2. V-shaped trough: Suitable for abrasive materials, the V-shape helps minimize wear on the trough walls, and the angled sides help prevent material buildup. V-shaped troughs have a smaller cross-sectional area compared to U-shaped troughs, which reduces material capacity.

3. Rectangular trough: Offers a larger cross-sectional area to increase material flow, ideal for high throughput applications.

4. Specialty troughs:

Insulating trough: Used for temperature-sensitive materials.

Cooling trough: Used to cool materials during transport.

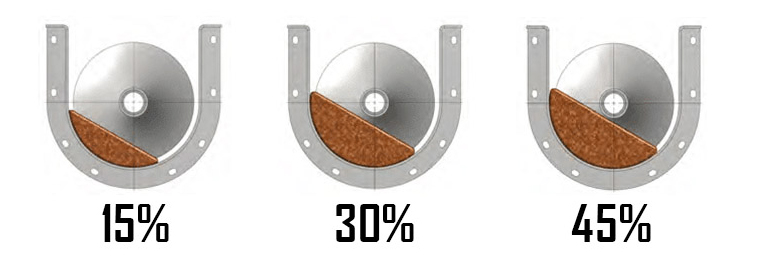

Depending on the properties of the conveyed material, the tank can be filled at 15%, 30% or 45%.

Specifically, the highest tank fill levels are for light, free-flowing, and non-abrasive particles, and lower tank fill levels (15% and 30%) are more effective for heavier, slower, and more abrasive materials. suitable.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.