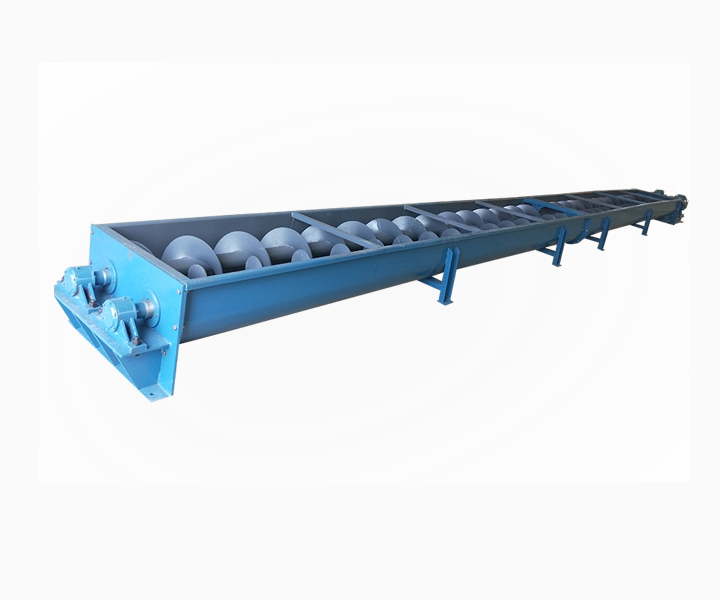

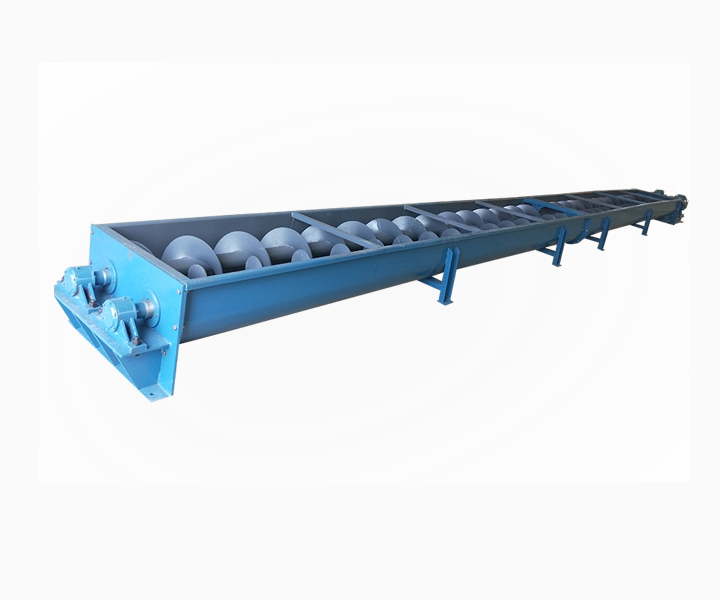

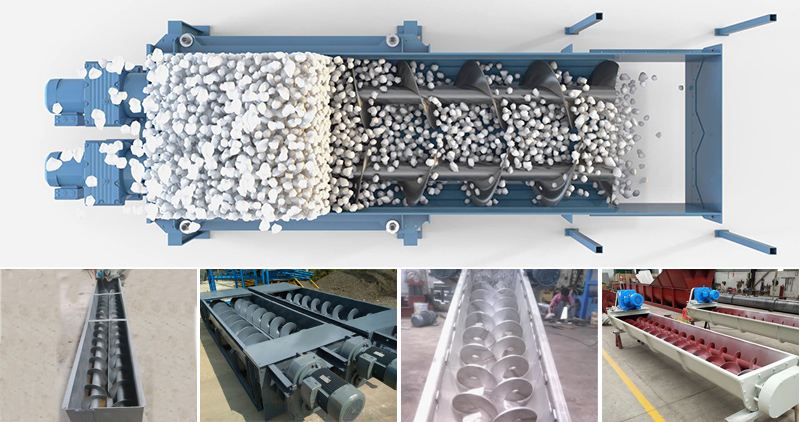

Double screw conveyor

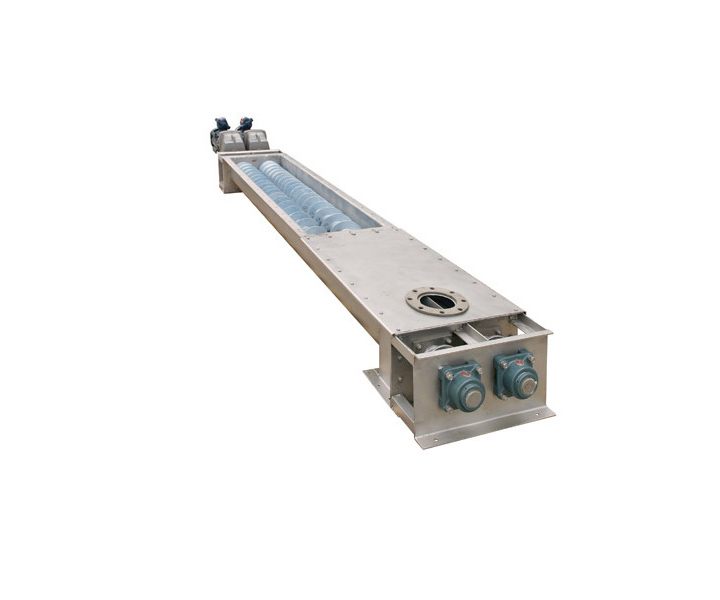

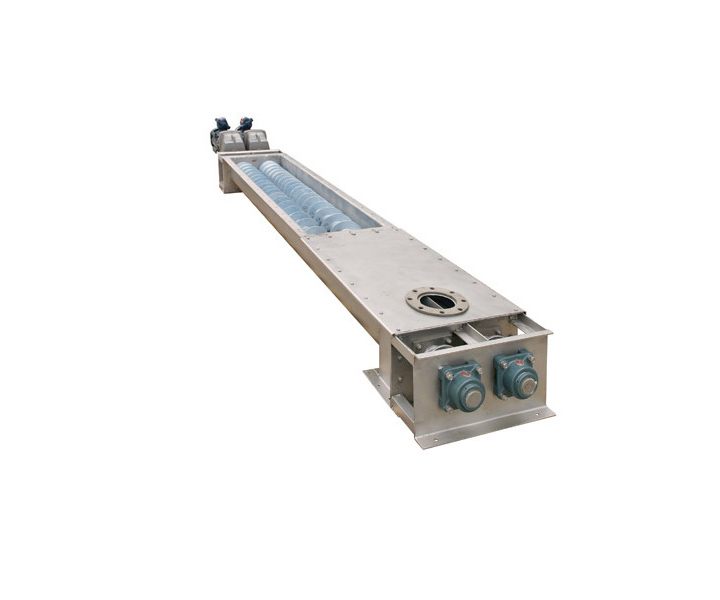

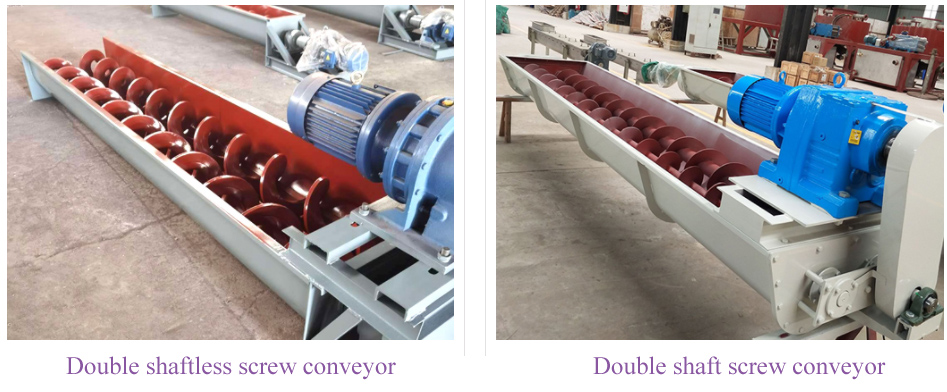

Double screw conveyor Double shaftless screw conveyor

Double shaftless screw conveyor Stainless steel double screw conveyor

Stainless steel double screw conveyor Carbon steel double screw conveyor

Carbon steel double screw conveyor Double shaft screw feeder

Double shaft screw feeder

Double-shaft design for conveying powdery, difficult-to-flow bulk materials with functions such as conveying, stirring, and mixing

![]()

![]()

![]()

Price:$500.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Width or Diameter: 200mm-600mm

Type: Double shaft or double shaftless

Conveying capacity: 134.2m³/hour

Conveying distance: 20 meters

Tilt angle: 0-15° Frame Material: SUS304/Carbon Steel

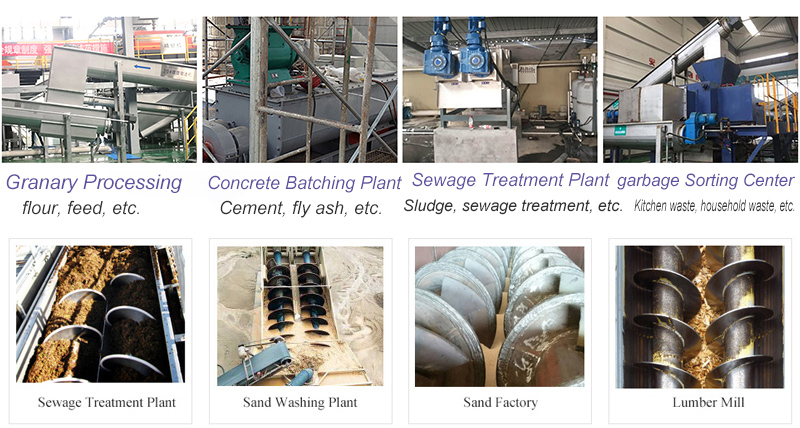

Application: It is suitable for conveying materials with poor flow performance, large volume or size, and needs to be stirred, such as straw, wood chippings, sawdust, bran, paper, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

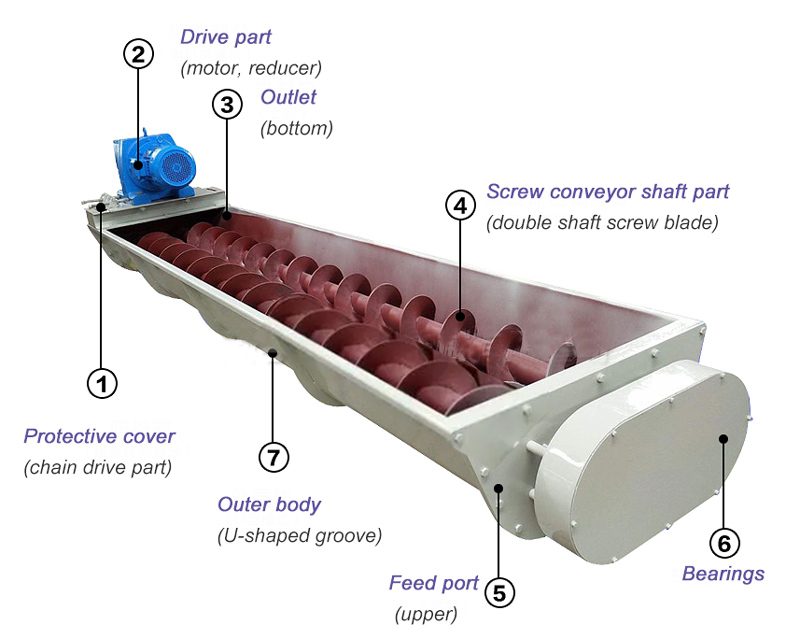

Double screw conveyor is installed with two screw shafts, one of which is left-handed and the other is right-handed. The two screw shafts turn to different directions, relying on the screw blades to push the material forward, and the material between the double shafts is between the screw blades. Alternately rotating and conveying back and forth, it can avoid the phenomenon of material blocking caused by accumulation of material.

In addition to conveying products, double screw conveyors also have functions such as mixing and stirring. They are mainly used for conveying materials with poor flow performance, large objects or large sizes that need to be stirred. Generally, they operate in a horizontal direction. Suitable for feeding below the silo.

Double-shaft screw conveyor: It can convey and is not easy to stick, and has a certain friction. It has certain requirements for the wear resistance of the screw conveyor.

Double shaftless screw conveyor: It can transport granular/powder/wet/paste, semi-flow graph/viscosity and other materials that are easy to entangle and block, such as sludge, etc. It is also suitable for materials with special hygiene requirements.

Double screw sonveyor is the choice for users who need particularly efficient unloading/feeding from a silo or hopper, it usually works horizontally and is suitable for feeding under the silo, the twin screw design provides for the transition of material from the hopper to the screw feeder Larger openings for handling heterogeneous materials (wood chips, paper, etc.), materials from the flour processing industry (bran, flour, etc.) and bridging materials (eg sawdust, soybeans, etc.).

Large delivery volume

The two screws rotate through a pair of gears at the shaft extension position. The flow rate of the blade is larger than that of the single screw blade, and the conveying capacity is 1.5-2 times that of the single-shaft screw conveyor.

Not easy to block

The two seamless steel pipes are respectively equipped with solid screws, and the two screw shafts turn to different directions, which can avoid the material blocking phenomenon caused by the stuck screw shafts.

Large feed port promotes difficult material flow

It can be loaded and unloaded at any point, intermediate feeding and multi-point feeding can be carried out at different positions, and the upper groove cover can be removed, which is convenient to check the operation status and clean up the remaining material in time.

Low cost

Due to the design of double helical shafts, it is equivalent to a mixer mixing materials at the same time, but the price is lower than that of a mixer, saving costs.

Sealing system

Sealed structure, the material will not overflow, and will not be polluted by other dust, which can prevent the material from being polluted or overflowing.

Easy to discharge and clean

There is a discharge valve at the lower end of the feeding port, and the screw can be reversed to discharge, so the discharge and cleaning are very convenient.

Double screw conveyor is mainly used for feeding powdery materials. It generally works horizontally and is suitable for feeding under the silo. In order to achieve uniform feeding and adjust the feeding capacity, the double helix and the single helix are at the same speed, because the helix angle of the double helix blade is higher than that of the single helix blade, so the conveying capacity of the double helix blade is larger than that of the single helix blade. In one week, the delivery volume of the double helix has increased to 1.5-2 times that of the single helix.

Sludge double screw conveyor

Clay double shaftless screw conveyor

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

Number of screw shafts: According to the different conveying volume, the number of screw shafts can be appropriately increased, but generally it is an even number, and it can be increased to 6 at most. The shorter the time, the shorter the time from the feed port to the discharge port, and the weaker the degree of mixing and stirring. The degree of stirring is stronger.

Motor power: It depends on the length and the degree of several screw shafts. The longer the length, the more the number of screw shafts. The less, the power of the motor used is correspondingly smaller. According to the length of the factory, if the length of the factory is limited, the screw shaft with more and shorter length can be appropriately selected. If the factory is long enough and the width is not enough, the screw shaft should be less and the length should be longer, so that the conveying volume will not be affected too much.

The double screw sonveyor is composed of two screw shafts. The direction of rotation of the rotating shaft determines the conveying direction of the material. Generally, the rotation direction of the two screw shafts is opposite in the design of the double screw conveyor, which can prevent the material from sticking to the screw shaft.

1. The connection between the screw shaft and the hanging bearing, the head and the tail shaft adopts the embedded tongue type, and the installation and disassembly do not require axial movement, and the maintenance is convenient. Long mandrel, less hanging and less failure points.

2. The variable diameter structure is adopted to increase the volume of the hanging bearing to avoid the contact between the hanging bearing and the material. The life of the hanging bearing can reach more than two years.

3. Each transmission part adopts the floating connection method, and the hanging bearing is a universal structure, so that the spiral body, the hanging bearing and the tail form an integral floating body, which can freely rotate and avoid the conveying resistance within a certain range, without jamming or blocking.

4. The head and tail bearing seats are outside the shell, and all bearings adopt multi-layer sealing box with sealing technology, and the bearing has a long service life.

5. Compared with other conveying equipment, it has the advantages of small cross-sectional size of the whole machine, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation, and simple maintenance.

Double screw conveyors are available in carbon steel and stainless steel. According to different production process requirements, the screw conveyor can be designed as:

(1) Feeding at the end, discharging at the end;

(2) Feeding in the middle, discharging at both ends at the same time or alternately discharging at both ends;

(3) Feeding at both ends and discharging at the middle;

(4) The end or middle, feeding, the other end or both ends are axially discharging.

Xinx iang Dahan double screw sonveyor manufacturer mainly produces double shaft screw conveyors and double shaftless screw conveyors. The models are complete and can be customized. Manufacturers provide one-stop services from design, drawing, modeling, processing, quality inspection, assembly, test machine, painting, delivery, etc., with bending machines, cutting machines, polishing machines and other processing equipment, as well as installation workshops, painting workshops, warehouses and other processing workshops. In addition, we also select and design according to the parameters you provide. We have 12 years of design and production experience, and the product quality is good.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.