For particle size classification and testing of powders, granules or suspensions.

![]()

![]()

![]()

Price:$20.00 - $200.00/Set

Consult now and enjoy a 10% discount

Diameter: 75/100/200/300mm

Mesh size: 5μm-150mm

Weight: 45kg

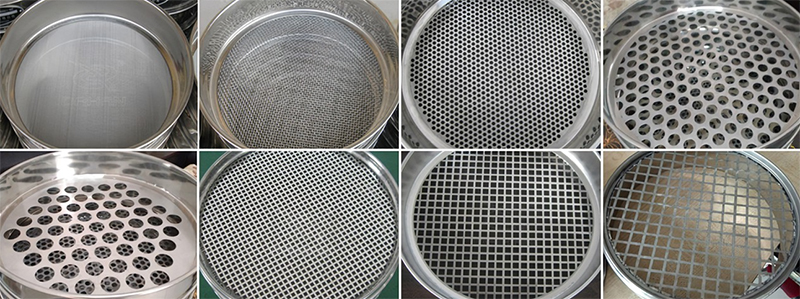

Screen type: metal woven mesh sieve (0.02mm-2.36mm), Perforated plate mesh sieve (: 1mm-125mm), electroforming sieve (75μm-5μm)

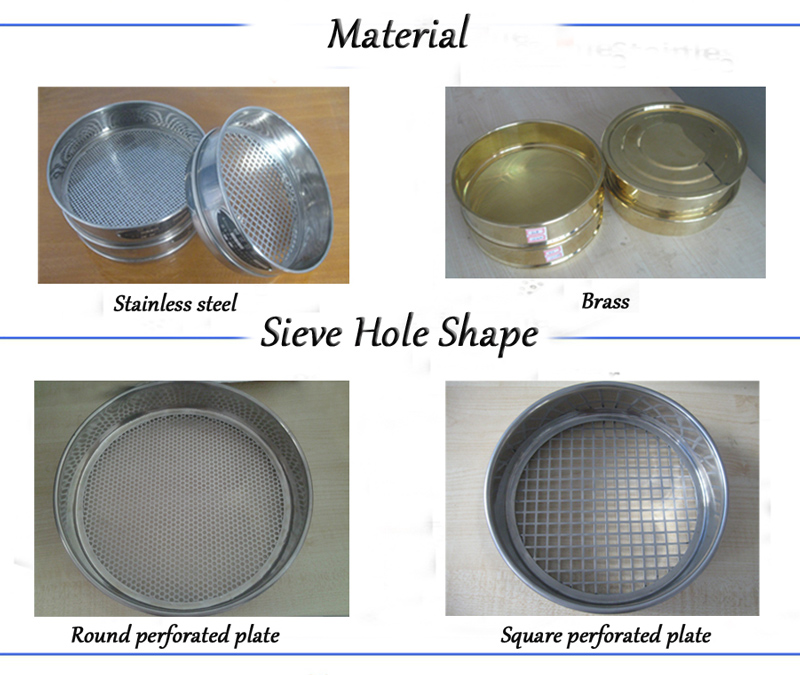

Material: Stainless Steel, Nylon, Brass

Hole shape: round hole, square hole, diamond hole

Application: For particle analysis of particle size distribution, impurity level, solid content and liquid content in testing departments such as laboratories and quality control departments.

Commitment:

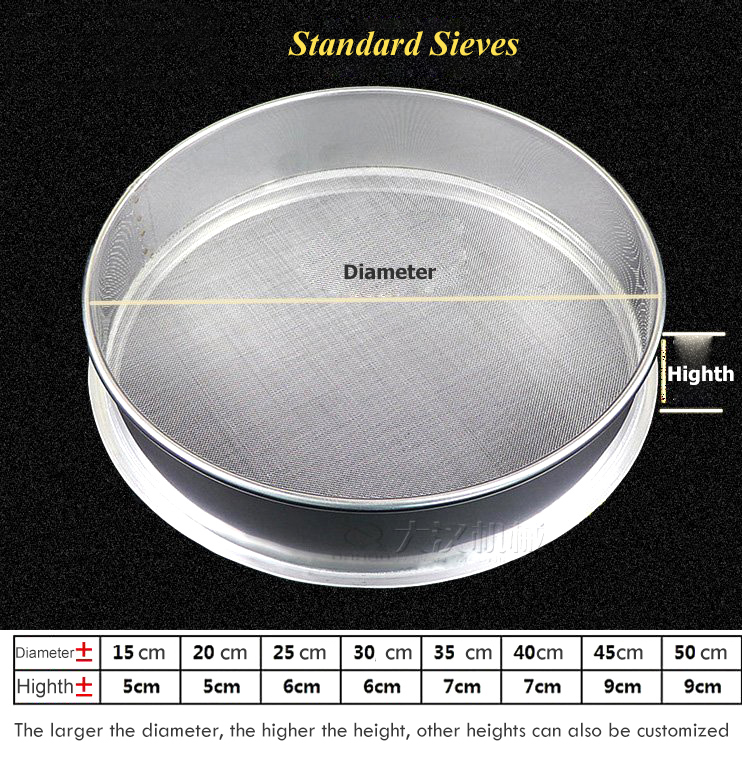

Standard sieve is an instrument for measuring particle size. It consists of a woven wire mesh with round or square holes. It is mainly used in laboratories for grading and particle size determination of powders, bulk particles and suspensions. The diameter is 75mm. , 100mm, 200mm, 300mm, 400mm, among which standard sieves between 200mm and 300mm are more common, which can quickly and effectively measure the size of solid particles from 125mm to 20 microns.

Standard sieves are a crucial tool in various industries, especially in materials testing, construction, and geological applications. These sieves come in a range of mesh sizes and are used to separate particles based on their size. Standard sieves adhere to various international standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). These standards specify the dimensions, materials, and tolerances for the construction of test sieves to ensure uniformity and accuracy in particle size analysis.

General model

Metal Wire Mesh Standard Sieve

National standard: GB/T6003.1-1997, ISO3310-1: 1990 R20/3, R20, R40/3 series

Mesh size: 2.36mm-0.038mm

Screen frame diameter: 75mm/200mm/300mm

Screen material: Brass, Tin Bronze, Stainless Steel

Application: High-precision screens, mostly used in the diamond industry

Metal Perforated Plate Standard Sieve

National standard: GB/T6003.2-1997, ISO3310-2: 1990 R20/3, R20, R40/3 series

Mesh size: 1mm-125mm

Screen frame diameter: 200mm/300mm

Screen material: copper

Application: particle size detection of materials with impact on the screen surface

Electroforming Standard Test Sieves

National standard: GB/T6003.3-1999/ISO3310.3

Mesh size: 5μm-500μm (tolerance 2-3um)

Screen frame diameter: 75mm

Screen material: stainless steel

Application: Produced by precise electrochemical method, suitable for laboratory high-precision powder detection

Special model

Wet Standard Sieves

Mainly used to simulate the screening of materials in a humid environment.

National standard: ASTM E11/ISO 3310-1

Mesh size: 4-325 mesh

Screen frame diameter: 75mm/200mm/300mm

Screen material: Brass, Stainless Steel

Standard Soil Sieves

Soil nitrogen content determination, soil potassium content determination, soil carbonate. determination, etc.

International standard: GB/T 14693-1993

Diameter: 200/300/400mm

Aperture: 0.074mm-60mm

Standard Pharmacopoeia Sieves

Used for screening medicines, medicinal materials or pharmaceutical excipients

International standard: GB/T6003-1997 (GB/T6003-2007), equivalent to international standard ISO3310

Sieve number: No. 1-9

Mesh size: 10-200 mesh

| NO. | Name | Application | Specification |

| 1 | Standard Soil Sieve | Analyzing the particle size distribution of soil, it is possible to separate soils of different fineness | 0.075mm, 0.25mm, 0.5mm, 1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 13mm, 20mm, 40mm, 60mm |

| 2 | Standard gravel screen | Determination of sand, silt and clay | 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100mm, with bottom cover or 2.36, 4.75, 9.5, 16, 19, 26.5, 31.5, 37.5, 53, 63, 75, 90mm, with bottom cover |

| 3 | Standard Pharmacopoeia Screen | Analysis and testing of pharmaceutical powders, pharmaceuticals, and pharmaceutical granules | 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh |

| 4 | Standard sieve for stone | For determination of particle size distribution of sand, aggregates, soil | 1, 1.7, 2.5, 3.15, 5, 7.1, 10, 16, 20, 25, 35.5, 40, 45, 56, 63mm |

| 5 | Standard sieve for cement | Check the fineness of cement | A total of 5 pieces, including the bottom and cover, the specifications are 0.125, 0.71, 0.9, 5, 20mm |

| 6 | Aggregate special standard sieve | Determining aggregate particle size distribution | 80, 60, 50, 40, 30, 25, 20, 10, 5, 2, 1, 0.5, 0.2, 0.075mm |

Standard sieve sizes are commonly used in various industries for particle size analysis and material separation. Here’s a brief overview of standard sieve sizes based on the ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards:

ISO Sieve Sizes (Metric Standard)

1.00 mm

0.500 mm

0.250 mm

0.125 mm

0.063 mm

ASTM Sieve Sizes (U.S. Standard)

No. 4: 4.75 mm (0.187 in)

No. 8: 2.36 mm (0.0937 in)

No. 16: 1.18 mm (0.0469 in)

No. 30: 0.595 mm (0.0236 in)

No. 50: 0.297 mm (0.0117 in)

No. 100: 0.149 mm (0.0059 in)

No. 200: 0.074 mm (0.0029 in)

Mesh Size: Refers to the number of openings per linear inch.

Opening Size: The diameter of the opening in mm or inches.

Sieving is a physical method of separating mixtures. It involves passing a mixture of particles of different sizes through a sieve or screen. Smaller particles pass through the sieve holes and larger particles are retained by the sieve.

Step 1: Raw Material Selection - Raw Material Screening

In terms of raw material selection, the machinery used by most manufacturers is not fine enough to screen the raw materials, so that the production process contains a lot of impurities, or cannot select good raw materials, and the purity of pharmaceutical raw materials cannot be well grasped. You need to use standard sieve for detection.

Step 2: Production Process - Filtration and Sieving

During the production process, due to various factors such as mechanical vibration, granular semi-finished products are easily broken and turned into small pieces or powder, which affects the output and quality. For liquids, it is more necessary to use experimental sieves for filtration and sieving to filter out impurities and detect the content of finished products.

Step 3: Finished Product - Screening Test

When the product is made into a finished product, it is necessary to select the finished product, and select a better product for packaging, which also requires analysis and screening.

High screening accuracy

Opening sizes from 5 inches (125 mm) to 635 mesh (20 microns) allow for "micro" sieving up to 5 μm.

Standards compliant

The mesh conforms to the GB6003.1-1997 standard, which can ensure the consistency and interchangeability of standard sieves of the same model produced at any time.

Multi-layer stacking use

It can be used singly or stacked in 8 layers (including sieve bottom), and a material can be continuously divided into 7 particle segments of different specifications.

304 stainless steel

The screen frame is made of SUS304 stainless steel by stretching and polishing, the wall thickness is 0.6mm, the gloss is uniform, durable, and non-magnetic.

High temperature resistance

The screen mesh and the screen frame are fixed by soldering to prevent the problem of loosening and shaking, and can work stably at a temperature of >300 degrees.

Can be timed

It can be equipped with an automatic control timer, which can be set from 1 to 99 minutes to ensure the repeatability and consistency of the experiment.

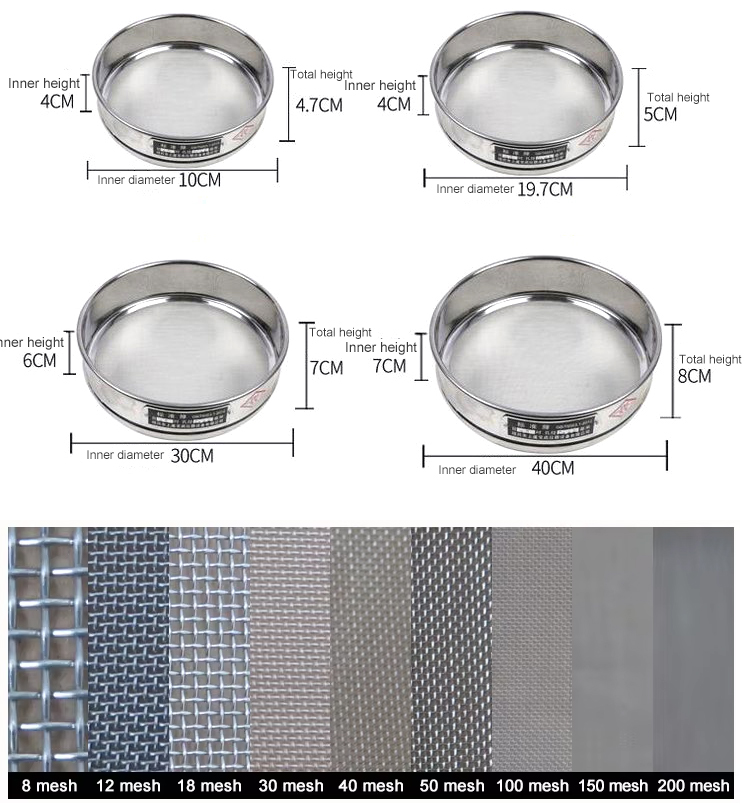

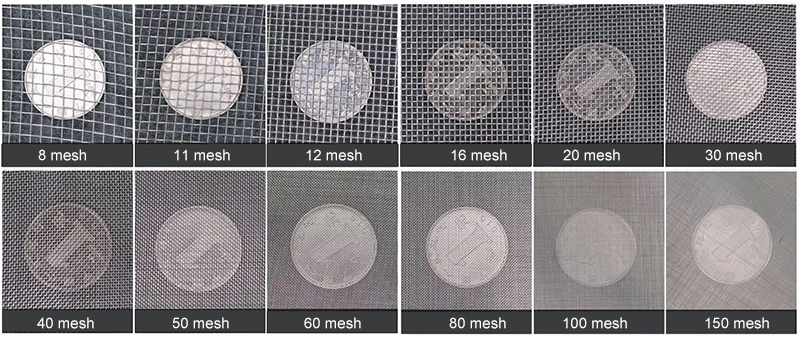

Definition of mesh: refers to the number of meshes in the area of 1 inch × 1 inch, that is, the number of meshes of the screen, and the number of meshes that the material can pass through the mesh is defined as the number of meshes: such as 200 mesh, it is the number of meshes. The material can pass through a screen with 200 meshes in 1 inch x 1 inch. By analogy, the larger the mesh number, the finer the material particle size, and the smaller the mesh number, the larger the material particle size.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

The standard sieve can be used for particle size structure detection of granular and powdery materials, liquid solid content and debris screening, filtration and particle size analysis. Widely used in scientific research and production departments, laboratories, quality inspection rooms in food, medicine, chemical industry, metallurgy, geological exploration, soil and other industries.

The following are specific applications:

| Product | Mesh size | Product | Mesh size | Product | Mesh size |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | Soybean | 4-5 mesh | Green beans | 10 mesh |

| Rice | 12-14 mesh | Rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| Flour | 50-60 mesh | Cereals | 40-50 mesh | Sesame | 22-24 mesh |

| Fried Chicken Burger Bread | 20-30 mesh | Mung bean powder | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine Pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Chinese Herbal Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Dregs | 60-150 mesh | Soy milk | 80-120 mesh | Honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

The specific industries are as follows:

1. Agriculture: Used in agriculture to analyze soil samples, separate seeds, and test the quality of fertilizers and compost.

2. Construction: Use standard sieves during construction to analyze the particle size distribution of aggregates such as sand, gravel, crushed stone, and other building materials.

3. Mining: Analysis of the particle size distribution of ores and other materials such as coal and limestone.

4. Food processing: used to separate and classify food ingredients such as flour, sugar and spices according to particle size.

5. Pharmaceuticals: Analyze the particle size distribution of pharmaceutical powders and other pharmaceutical ingredients.

6. Environment: Used for environmental testing, analyzing the particle size distribution of sediment samples, and monitoring air and water quality.

Standard sieve standards are sets of specifications that define the dimensions, materials, and performance requirements for sieves used in particle size analysis. These standards ensure consistency and comparability between measurements made using different sieves.

ASTM (American Society for Testing and Materials): This is the most widely used standard in North America. It specifies sieve sizes in terms of mesh number, which is the number of wires per linear inch in the mesh.

ISO (International Organization for Standardization): This standard is used globally and specifies sieve sizes in millimeters.

BS (British Standard): This standard is used in the United Kingdom and specifies sieve sizes in terms of mesh number.

Key aspects covered in standard sieve standards:

Mesh size: This is the size of the openings in the mesh and is specified in terms of mesh number (ASTM/BS) or millimeters (ISO).

Material: The material used to construct the sieve, typically stainless steel or brass.

Tolerance: The allowable variation in the dimensions of the sieve.

Testing methods: Procedures for verifying the accuracy of the sieve.

By adhering to these standards, researchers and engineers can ensure that their particle size measurements are reliable and comparable to those obtained by others using the same or similar sieves.

There are several types of sieve machines that can be matched with standard sieves, including:

Ultrasonic sieve shaker: It is an ultrasonic sieving system added to the conventional model, with higher and more accurate inspection accuracy. It is a commonly used inspection equipment for mesh blockage when the laboratory is doing fine powder sample screening.

Rotap sieve shaker: It has two vibration forms of slapping and reciprocating. It is fast in feeding and not easy to block. It is suitable for laboratory screening and testing of materials, especially for the production and classification process of diamond micropowder and superhard materials. It has high strength and large Repeatedly used frequently.

Magnetic levitation sieve shker: covers mechanical physical vibration and high-frequency electromagnetic vibration, and integrates three functions into one - up and down vibration, back and forth reciprocating motion, and left and right swing, so that the material generates a reciprocating suspension motion inside, and screening any material will not Residue on the mesh, the fine can be sieved to 5 microns.

Electromagnetic sieve shaker: It adopts electromagnetic drive and three-dimensional movement, and can sieve to 20 microns (635 mesh), which solves the problem of ultrafine powder dry sieving.

Xinxiang Dahan Vibration Machinery Co., Ltd. mainly produces standard sieves, standard soil sieves, standard pharmacopoeia sieves, standard vibrating sieves, ultrasonic test sieves, magnetic suspension test sieves and other experimental sieves. Screening of the particle size structure, liquid solid content and debris amount of granular and powdery materials by scientific research and production, laboratories, quality inspection rooms and laboratories of colleges and universities in the departments of powder, building materials, national defense, and geology, etc. Filtration and detection are also commonly used in the fields of ordinary abrasive particle size composition inspection and superhard material production grading.

The manufacturer promises: Standard parts are in stock, 7 working days for special customization, free shipping from the manufacturer, and quality problems within 30 days, users can choose free maintenance or replacement, one-year warranty, and lifetime warranty.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.