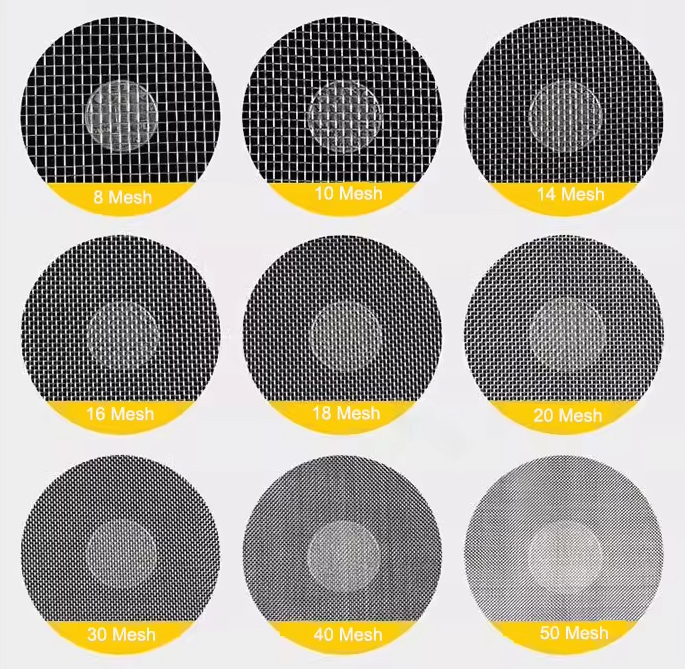

Standard sieves are mainly used for particle size classification and detection of powders, granules or suspensions. There are strict mesh size standards. Standard sieves for different purposes have mesh sizes ranging from 20um to 125mm. Most of them use mesh as the unit. Commonly used ones are American, British and European standards.

The mesh size of a standard sieve refers to the size of the mesh holes on the sieve. This size is usually expressed in mesh, that is, the number of holes per unit area. There are two common types: mesh and sub-mesh. Among them, mesh refers to the number of sieve holes per inch, and sub-mesh refers to the number of sieve holes per inch divided by the exponential power of 2. For example, the mesh number of a 200-mesh sieve is 200 holes per inch, and the sub-mesh number of a 400-mesh sieve is 200 holes per inch*(1/2)^2=50 holes per inch.

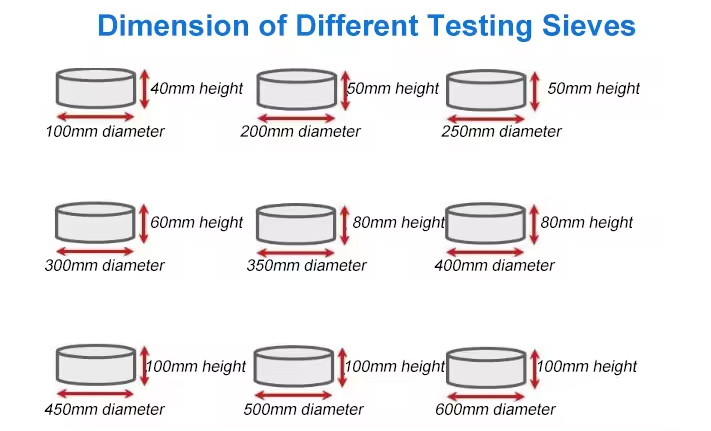

The diameters of standard sieve models are 75mm, 100mm, 200mm, 300mm, and 400mm, among which the standard sieves between 200mm and 300mm are more common.

American standard sieve:

20 mesh: 8400um

30 mesh: 6000um

40 mesh: 4200um

50 mesh: 2970um

60 mesh: 2500um

80 mesh: 1770um

100 mesh: 1490um

120 mesh: 1250um

140 mesh: 1050um

170 mesh: 880um

200 mesh: 740um

230 mesh: 630um

270 mesh: 530um

325 mesh: 440um

400 mesh: 370um

1. Standard soil sieve: used to analyze the particle size distribution of soil, It can separate soils of different finenesses. Commonly used apertures include: 0.075mm, 0.25mm, 0.5mm, 1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 13mm, 20mm, 40mm, 60mm

2. Standard gravel sieve: used for the determination of sand, silt and clay. The specifications are 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100mm, with bottom cover or 2.36, 4.75, 9.5, 16, 19, 26.5, 31.5, 37.5, 53, 63, 75, 90mm, with bottom cover

3. Standard pharmacopoeia sieve: mainly used for pharmacopoeia units to analyze and test pharmaceutical powders, medicines, and pharmaceutical granules. There are 9 kinds of sieves, and the No. 1 sieve has the largest sieve hole. The specifications are: 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, and 200 mesh.

4. Special standard sieve for stones: a total of 15 pieces, including a set of bottom and cover, with specifications: 1, 1.7, 2.5, 3.15, 5, 7.1, 10, 16, 20, 25, 35.5, 40, 45, 56, and 63mm.

5. Standard sieve for sand: square copper mesh, specifications are: 2.5, 1.25, 0.63, 0.315, 0.16, 0.08

6. Standard sieve for cement: cement standard sieve is used to detect the fineness of cement, a total of 5, also with a bottom and a cover, specifications are 0.125, 0.71, 0.9, 5, 20mm.

Different sieve hole sizes are suitable for screening different materials. Generally speaking, the smaller the sieve hole size, the finer the particle size of the screened material. If you want the screened material to achieve a certain grading effect within a certain range, you must choose a suitable sieve hole size.

The material of the screen also has a great influence on the screening effect. Generally speaking, screens with smaller sieve hole sizes are often made of stainless steel wire, which has good acid and alkali resistance and wear resistance, and can effectively improve screening efficiency and service life. Screens with larger sieve hole sizes are generally made of ordinary steel wire.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.