Small linear vibrating screen refers to a linear vibrating screen with a length of 500mm and a width of less than 2000mm, such as DZSF-515 and DZSF-520. Generally, it is suitable for workshops with a small production volume, or a large number of equipments are used at the same time. .

Small linear vibrating screens are usually used for screening and grading of granular materials. Their main functions include:

Screening and filtering: Screening the raw materials, classifying the granular materials into different grades according to their size, and filtering out unnecessary particles.

Dust removal: Small linear vibrating screens can separate impurities and dust from granular materials to achieve dust removal.

Improving production efficiency: It can help improve production efficiency, classify granular materials according to required specifications, and reduce the workload of manual sorting.

Fine screening: Small linear vibrating screens can achieve fine screening of granular materials, improve product quality and particle size uniformity.

Filtration of powder and liquid: Small linear vibrating screens can also be used for filtering powder and liquid to achieve separation of solid particles and liquid.

| Model | Layer | Screening Area | Mesh Size | Particle Size | Capacity | Power | Vibration Direction Angle | Screen Inclination | Dual Amplitude |

| (mm) | (mesh) | (mm) | (t/h) | (kw) | (°) | (°) | |||

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 |

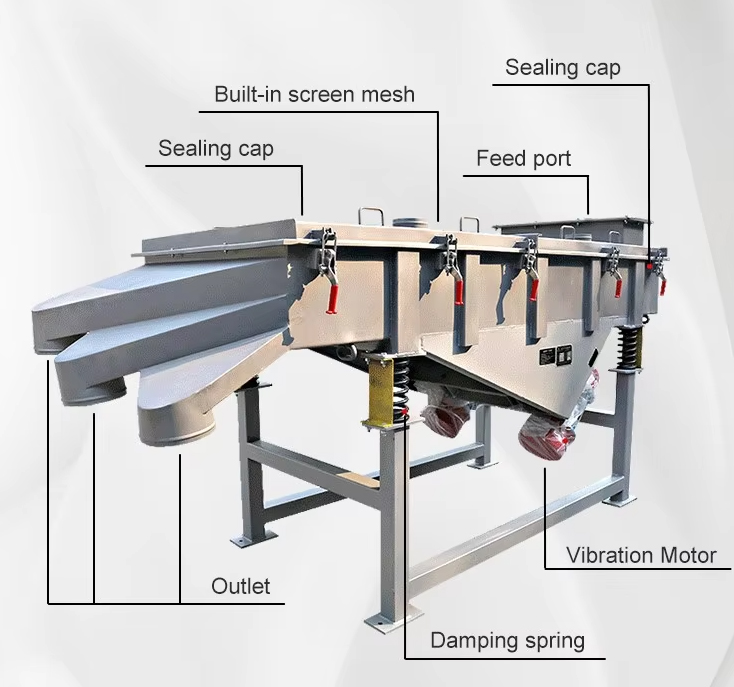

Small linear vibrating screens are usually composed of the following main parts:

Vibration motor: The motor that drives the entire vibrating screen to vibrate, usually installed at the bottom or side of the screen machine.

Screen box: The screen box is the part with the screen, which is used to hold the granular material for screening.

Screen: The screen is a screening device installed inside the screen box. Depending on the required screening particle size, screens of different specifications and apertures can be used.

Support device: The support device is used to support and fix the various parts of the vibrating screen to ensure the stability of the entire equipment.

Feed port: The channel for granular materials to enter the vibrating screen, usually located at the top of the screen machine.

Discharge port: The channel for the screened material to be discharged from the vibrating screen, usually located at the bottom of the screen machine.

Control system: A control system used to control the start and stop of the vibrating screen, vibration intensity and other parameters.

The small linear vibrating screen is powered by the motor and is transmitted to the screen, so that the material is scattered on the screen and thrown up, and moves forward at the same time. The bottoms are discharged from their respective outlets.

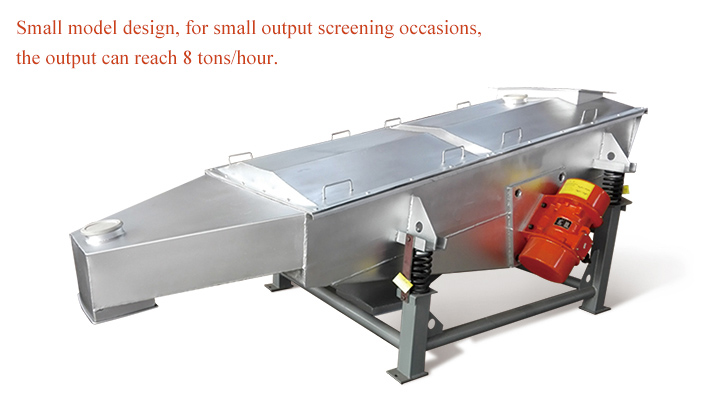

1. Small model design, for small output screening occasions, the output can reach 8 tons/hour.

2. It is used for sieving between particles of different sizes, the sieving is as fine as 400 mesh, and the sieving efficiency can reach more than 96%.

3. 2-7 kinds of finished products of different specifications can be obtained in one operation, and the sorting efficiency is high.

4. Fully enclosed structure, basically no dust during the screening process, reducing environmental pollution

The Small linear vibrating screen can screen dry powder and granular materials with a moisture content not higher than 7%, such as tea, limestone, quartz sand, feed, chemical fertilizers and other materials with large output requirements and low precision requirements. The adjustment of the number carries out the impurity removal and classification of the material.

A food processing company purchased a small linear vibrating screen to screen small particles of food and improve product quality. The vibrating screen is compact, easy to clean and maintain, and meets food hygiene standards. Through the use of the vibrating screen, the company has achieved efficient particle screening, reduced labor costs and production time, improved production efficiency and product quality, and met customers' requirements for food quality and safety.

Dahan small linear vibrating screen, we have many years of production experience and technical accumulation. Our vibrating screen is made of high-quality materials, with a stable structure and reliable performance. It is widely used in food, chemical, pharmaceutical, building materials and other industries. At the same time, we also provide customized services, customizing vibrating screens of different specifications and functions according to customer needs. Therefore, the price will also vary according to your needs. If you want to know more about our small linear vibrating screen, we will wholeheartedly provide you with high-quality products and services!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.