Pharmaceutical linear vibrating screen is a rectangular vibrating screen made of stainless steel. The commonly used stainless steel materials are 304, 304L, 316, 316L, etc. They all have the characteristics of anti-corrosion, anti-rust and high temperature resistance, and are specially used in the pharmaceutical industry. Screening, grading, and impurity removal of powdery and granular materials, and coarse filtration of solid-liquid mixtures. It is a light-duty screening equipment with large processing capacity and high screening efficiency.

Pharmaceutical linear vibrating screen is suitable for screening powders and granules in the pharmaceutical industry, such as cephalosporins, microspheres, steroids, lipids, peptides, nucleotides, antibiotics, proteins, vitamins, pellets, decoction pieces, bulk drugs, APIs, Chinese medicine pills, Chinese medicine formula granules, Chinese medicine powder, etc.

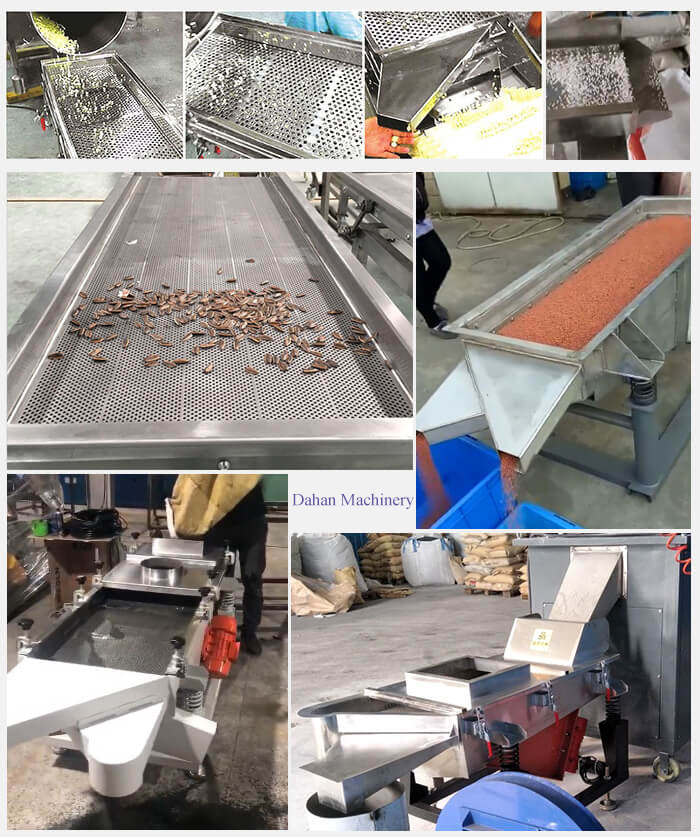

The pharmaceutical linear vibrating screen has an inclination angle relative to the screen surface by the rotating shafts of two vibrating machines. Under the combined force of the exciting force and the weight of the material, the material is thrown up on the screen surface and jumps forward, moving forward in a straight line. After a large number of crushed materials of different particle sizes and mixed coarse and fine particles enter the screen surface, only a part of the particles In contact with the screen surface, due to the vibration of the screen box, the material layer on the screen is loosened, thereby removing the gaps existing in the large particles and further expanding, and the small particles take the opportunity to pass through the gap and transfer to the lower layer, because the gap between the small particles is very small, Large particles cannot pass through, so the original disordered particles are separated, that is, stratified according to particle size, forming the arrangement rule of small particles on the bottom and coarse particles on the top, so as to achieve the purpose of sieving and classifying materials.

Pharmaceutical linear vibrating screen is mainly made of SUS304 stainless steel, which is resistant to corrosion, high temperature, not easy to rust, clean and hygienic. It has the following advantages:

1. The material is safe and easy to clean: 304 or 316L stainless steel is used, which is anti-corrosion, rust-resistant and high-temperature resistant. The surface of the equipment and the welding points are carefully polished and polished, so that there will be no powder hanging during the screening process, which is convenient for cleaning and disinfection.

2. All rubber accessories must also meet the hygienic standards of medicine (silicon material), and the screening equipment required by the pharmaceutical industry must pass the production standards.

3. Fine screening: The single-layer screen can complete 200 mesh fine screening, which can meet the screening processing capacity of 10 tons of large output.

4. Sealing structure: In order to ensure the sanitation of raw materials, the stainless steel linear vibrating screen adopts two measures of dust cover and sealing strip to ensure the sealing of the equipment. It is absolutely impossible for various materials in the same workshop to contaminate each other and affect the production process.

Pharmaceutical linear vibrating screen for pharmaceutical granules

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.