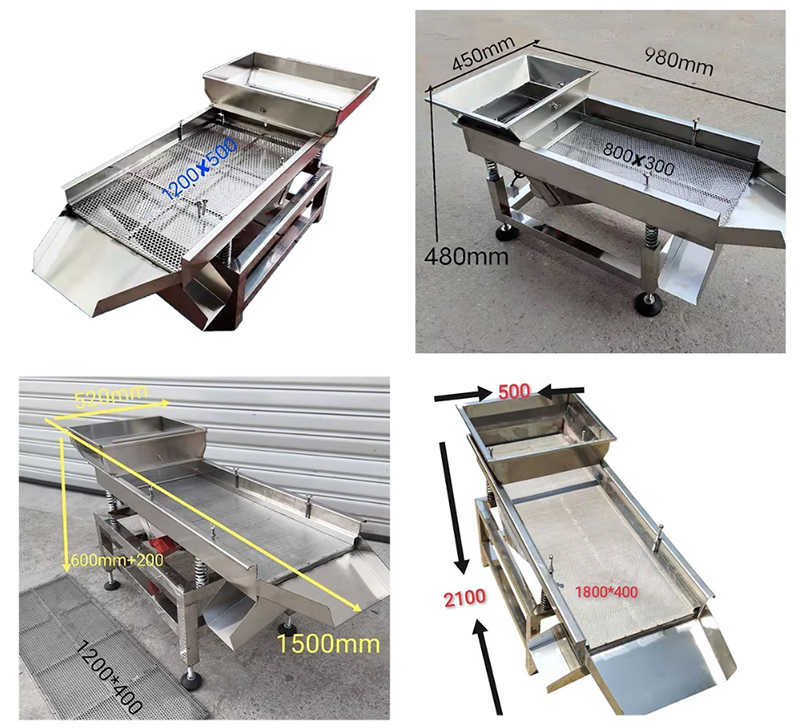

Small stainless steel linear vibrating screen is a small vibrating screen with compact size and structure. The screen diameter is 400mm and the processing capacity can reach 100 kg per hour. It is suitable for small-scale production lines, such as small processing plants or trial production lines. It is used for preliminary screening and separation of materials. It has small dimensions and lightweight structure, suitable for use in limited space or places that need to be moved.

Small stainless steel linear vibrating screen is made of polished 304 or 316L stainless steel. There is no weld at the weld, which is easy to clean, ensuring that there is no material deposition and avoiding contamination of the screened product. All rubber parts are made of silicone. It is suitable for screening and filtering of dry and wet materials that require cleanliness and acidity, such as flour, feed, powder, plastic particles, etc.

Small stainless steel linear vibrating screen can be used to screen dry powder or granular products such as flour, API, juice, soy milk, rice, Chinese medicine powder, wheat, sesame, coffee, spices, Chinese medicine tablets, capsules, as well as wet products and liquids. It can remove foreign matter from the product by continuous filtration and can be used in pharmaceutical, chemical, food, metal powder and other industries.

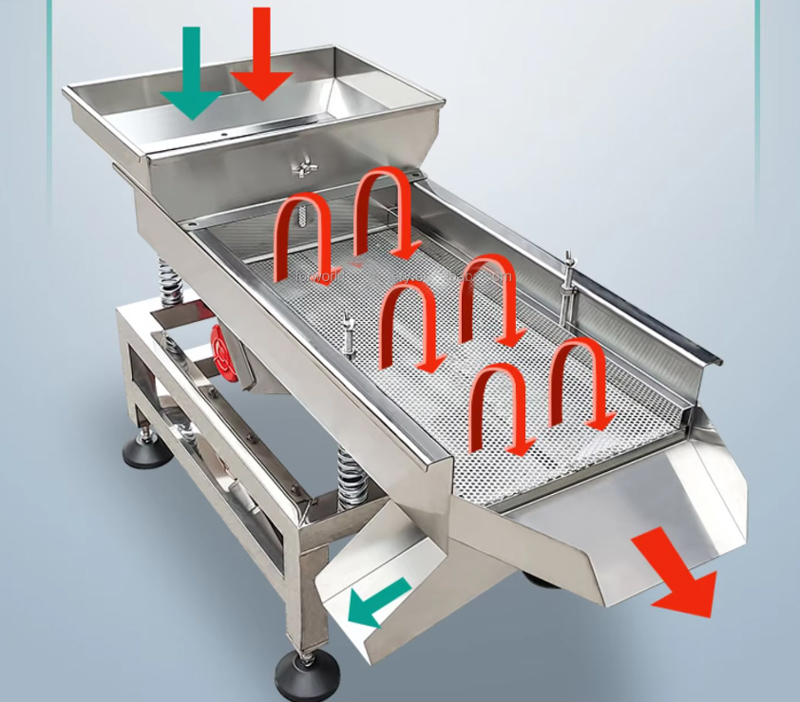

Removal of impurities: Usually a 1-layer screen, usually fine products passing through the screen will be retained as high-quality products, and can also be used to remove broken or undersized products. In most production environments, it is either to prevent contamination in the process or to perform quality checks before packaging machines.

Grading: Separate particles of different sizes from the product so that the final material is classified into different sizes. Since the particle size is very close to the aperture, the throughput of the grading screen is usually much slower than that of the garbage screen, however, this can be compensated by a larger screen area or fine-tuning the motor weight setting.

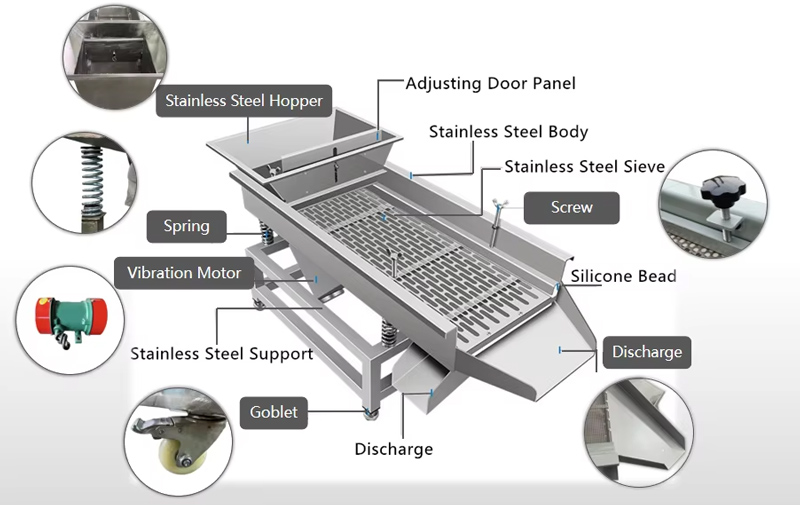

Material: Made of high-quality stainless steel material to ensure durability, corrosion resistance and suitability for handling a variety of materials.

Size: Compact and small, ideal for applications with limited space or processing small amounts of material.

Screening efficiency: Designed to provide high screening efficiency and accuracy, ensuring effective separation of materials based on size.

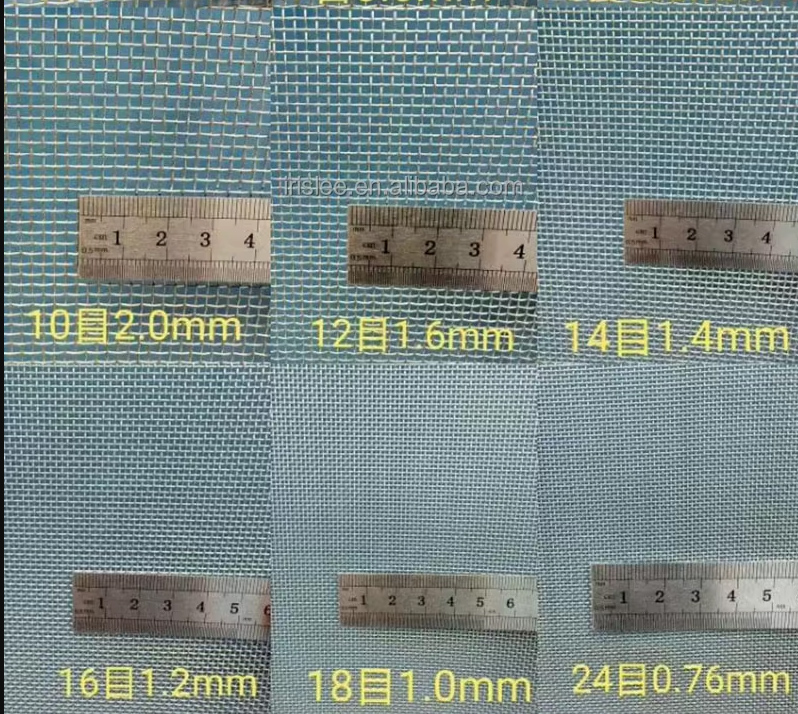

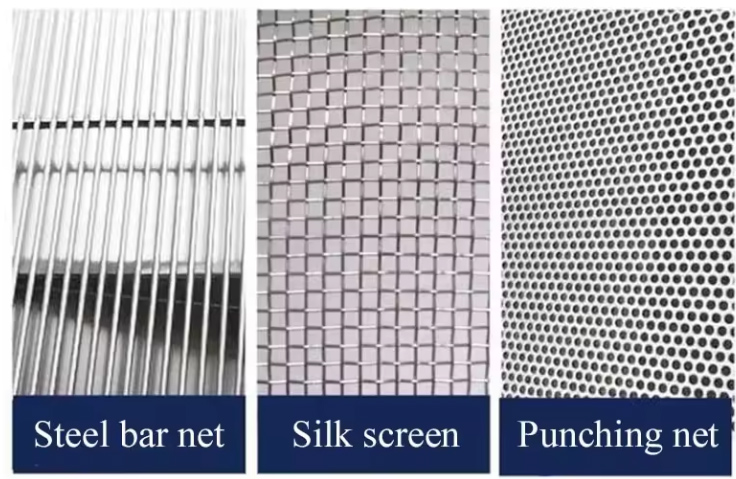

Mesh size: Equipped with mesh screens with customizable mesh sizes to meet different particle size requirements and achieve the desired separation.

Vibration motor: Driven by a vibrating motor that produces linear vibrations, facilitating the movement of materials on the screen for efficient screening.

Adjustable settings: Usually have adjustable vibration intensity, screen inclination and other parameter settings to optimize the screening process for different materials.

Application: Suitable for a wide range of applications, including food processing, pharmaceuticals, chemicals, mining and other industries that require particle separation or classification.

Capacity: Depending on the model and design, the capacity of the vibrating screen may vary, typically ranging from a few kilograms to several tons per hour.

Small vibrating screens have relatively small processing capacity and are suitable for screening and separation of small batches of materials.

Laboratory and R&D: Used in laboratory and R&D fields for screening and grading small batches of materials. It can be used to evaluate the particle characteristics, distribution and screening effect of materials, and provide data support for subsequent process and product development.

Food processing: It can be used for grain screening in grain processing, grading of food raw materials, screening of powdered foods, etc. Small vibrating screens can help improve the quality and safety of food and meet the requirements of different particle sizes.

Chemical industry: It is used for screening of chemical raw materials, grading of granular products, screening of powders, etc. Small vibrating screens can help improve the quality and uniformity of chemical products and meet specific particle requirements.

Pharmaceutical industry: It can be used to detect the particle size and particle distribution in pharmaceutical particles to ensure the quality and consistency of medicines. Small stainless steel linear vibrating screen offers reliable performance, easy maintenance, and versatility in screening various materials efficiently.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.