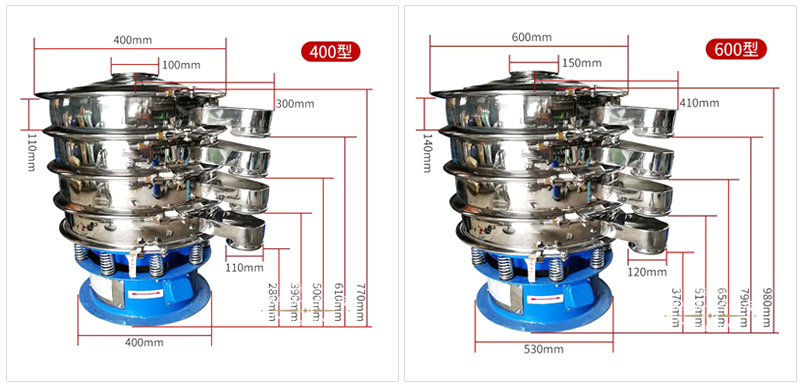

Mini vibrating screen, also called small vibrating screen, is small in size. Commonly used machines have a diameter of 400mm or 600mm, allowing a processing capacity of 100kg-500kg per hour. Its compact size does not require excessive floor space and can be easily installed to the production line, and the machine is small and can be moved flexibly.

Mini vibrating screen can be used for screening of small and medium batches in various industries, it can be used for the separation process of solids in liquid, for the separation of different particle sizes of the same product, for safe screening to remove foreign matter, for particle homogenization, etc., suitable for screening 36 microns to 25 mm.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 |

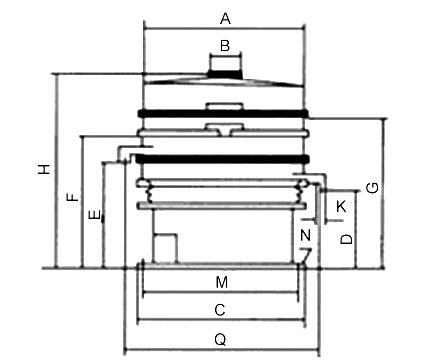

| Model | A | B | C | D | E | F | H | I | 1 deck height (mm) |

2 deck height (mm) |

3 deck height (mm) |

Vibarion motor (kw) |

| DH-400 | 330 | 305 | 240 | 400 | 80 | 70 | 320 | 390 | 635 | 770 | 870 | 0.18 |

| DH-600 | 530 | 430 | 246 | 600 | 100 | 70 | 391 | 415 | 785 | 910 | 1040 | 0.25 |

Purchase notice: Mini vibrating screen is made of ordinary steel, stainless steel and carbon steel. For special requirements on material contact, all stainless steel is required. Ordinary mini vibrating screens are mostly made of ordinary steel and stainless steel, and are mostly used for screening fine powder, micro powder, and dry and wet materials. The mini vibrating screen can be completely made of ordinary carbon steel or stainless steel, but due to cost considerations, the solution that the screening body is stainless steel + carbon steel base is mostly used. Users need to choose the material they need according to their own usage.

1. Removal of impurities: used to remove broken or undersized products, such as agglomerates and other contaminants, for final quality inspection.

2. "Size classification" is similar to the inspection sieve, but provides more accurate separation of sieving products. The purpose of the grading sieve is to accurately separate particles of different sizes from the product, so that the final material can be classified into different sizes. This is usually done by Pass the product through up to 5 meshes of different aperture sizes.

3. Solid-liquid separation: It can quickly remove insoluble solid substances in various slurries, most of which are single-layer, but can also be used in multiple layers.

1. The design of small model can meet the needs of users with small output, and the output can reach 100 kg/hour.

2. Made of 304 stainless steel, corrosion-resistant, high-temperature resistant, clean and hygienic.

3. The mesh is not blocked, the powder is not flying, and it can be sieved to 400 mesh or 0.028mm.

4. Impurities and coarse materials are automatically discharged, and continuous operation is possible.

The small vibrating screen is capable of simple safety screening and accurate grading of powder or granules, protecting the quality of powder or liquid products by removing oversized contaminants, grading wet or dry materials up to five parts in one operation, suitable for Various powders and slurries are used in small batch production. In addition to its small footprint, the vibrating screen is completely portable, allowing one device to be used at different locations in the plant.

| Screening Products | Mesh Size | Capacity (kg/h IT/h) |

| Pharmaceutical powder | 100-300 mesh | 400-600 |

| Flour | 20-80 mesh | 1000 |

| Cocoa powder | 300 mesh | 700 |

| Grind coffee | 20-80 mesh | 400-800 |

| Honey | 80 mesh | 200 |

Address::China,Yanjin county forest park gate to the west 1000 meters north road.