Using the electromagnetic vibrator as the vibration source, it adopts high-frequency up and down vibration to sieve to 20 microns (635 mesh), which solves the problem of ultrafine powder dry sieving.

![]()

![]()

![]()

Price:$200.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

Diameter: 75mm, 100mm, 200mm

Mesh size: 20 microns (635 mesh)

Vibration frequency: 3000 times/min

Can put sieve: 1-8 layers

Sample weight: 2 kg

Dimensions (L×W×H): 435*350*720mm

Weight: 55kg

Application: Used for particle separation and material particle size analysis and detection, dry screening to 5 microns; mainly used in soil research, laboratory and industrial fields, specific materials include: flour, aggregate, coal, pigment, soap, cement, powder , feed, sesame, abrasive, etc.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Electromagnetic sieve shaker is a laboratory instrument, which uses electromagnetic drive to generate controlled vibration to make particles pass through the sieve. The vibration frequency reaches 3000 times/min. The dry sieve can sieve to 20um (635 mesh), and the negative pressure device can be added. Dry sieving to 5um solves the problem of ultrafine powder dry sieving. The height of the sieve machine can hold 8 layers of sieves (including the bottom of the sieve), which can precisely separate a kind of granular material into 2-7 particle size segments at the same time.

Electromagnetic sieve shakers are preferred over other types of mechanical sieve shakers because they produce more uniform and controlled vibrations, resulting in more accurate and repeatable results. They are widely used in quality control and research applications in industries such as pharmaceuticals, food processing and chemicals, where particle size analysis is critical to product quality and consistency.

Electromagnetic sieve shakers are widely used in various industries for particle size analysis and quality control purposes, and can dry sieve down to 5 microns. Here are some common uses of electromagnetic sieve shakers:

Chemical Industry: For particle size analysis of chemicals such as powders, granules and pellets. They are also used for quality control of raw materials and finished products.

Pharmaceutical industry: For particle size analysis of active ingredients and excipients. They are also used for quality control of tablets and capsules.

Food Industry: For particle size analysis of various foods such as flour, sugar and spices. They are also used for quality control of food ingredients and finished products.

Mining industry: For particle size analysis of minerals, ores and other geological materials. They are also used for quality control of mining products.

Environmental Industry: For particle size analysis of soil, sediment and other environmental samples. They are also used for quality control of environmental monitoring instruments.

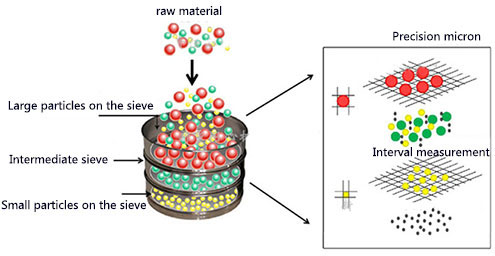

The electromagnetic vibrator is used as the vibration source. The vibration of the electromagnetic vibrator drives the low-position vibration of the sieve machine, and then passes through the base to a set of standard test sieves arranged from coarse to fine on the base. At the same time, the vibration motor (or reciprocating mechanism) installed on the lower part The materials are selected and screened, and the materials are vibrated on the screen surface of the standard inspection sieve, so that the material particles smaller than the pore size of the screen are sieved into the lower inspection sieve, and the layers are screened, only each layer of the test sieve has the same particle size , to achieve separation of different particle sizes.

Accurate and Repeatable Results

Electromagnetic drives create controlled vibrations, ensuring accurate and repeatable results, which is important for product quality and consistency.

Wide range of applications

Can be used for particle size analysis of various materials including chemicals, minerals, pharmaceuticals and food. They are also used for quality control in various industries.

High capacity

A large number of samples can be processed and multiple sieves can be accommodated simultaneously, saving time and increasing productivity.

Easy to use

Easy to operate with minimal training required. They are also equipped with digital controllers for precise control of the sieving process.

Minimal noise and vibration

Generates minimal noise and vibration, which makes them suitable for use in laboratory environments.

Low maintenance cost

Requires minimal maintenance and is designed for long-term use, making it a cost-effective solution for particle size analysis and quality control.

The main difference between an Electromagnetic Sieve Shaker and an ordinary sieve shaker is the method used to generate the vibration that causes the particles to pass through the sieve mesh.The table below shows you the difference between the two sieve shakers:

| Comparison item | Electromagnetic Sieve Shaker | Ordinary Sieve Shaker |

|

|

|

| Application | Dry sieve can sieve to 20μm (635 mesh), add negative pressure device, can dry sieve to 5μm. | 200 mesh or more coarse mesh, more than 200 mesh is easy to block the screen |

| Screening effect | Electromagnetic drives are more precise and produce more uniform vibrations for more accurate and repeatable results. | Using a mechanical drive, such as an electric motor, to create the oscillatory motion that causes the screen to vibrate, test results may be less precise and less consistent. |

| Capacity and number of sieves | Typically up to 8 to 10 sieves | Typically holds up to 4 or 5 sieves |

Electromagnetic Sieve Shaker for Metal Powder

Electromagnetic Sieve Shaker for Flour

| 200 | 200 | ||

| Sieve Shaker Type | Electromagnetic | ||

| Dry Test | YES | ||

| Wet test | YES | ||

| Power Levels | 9 | ||

| Particle’s Size* | From 20 μm to125 mm wet From 40 μm to 125 mm dry |

||

| Number of sieves (mm) | 7 (ø200/203 X 50 mm alt.) 14 (ø200/203 X 25 mm alt.) |

8 (ø200/203 X 50 mm alt.) 16 (ø200/203 X 25 mm alt.) |

5 (ø300 X 80 mm alt.) 8 (ø305/315 X 55 mm alt.) |

| Sieves diameter (mm) | 60 to 203 | 60 to 203 | 250 mm to 315 mm** |

| Timing (min) | 1 to 99 | ||

| Tension | 220/240 V – 50/60 Hz. | ||

| Intensity (A) | 1,8 | ||

| Power(kW) | 0,4 | ||

| Weight (Kg)> | 27 | 40 | 45 |

| Interval | 1 to 9 s | ||

| Max. Width | 2 mm | ||

| Dimensions (LxAxh) mm | 375 x 630 x 700 | 360 x 300 x 800 | 400 x 300 x 800 |

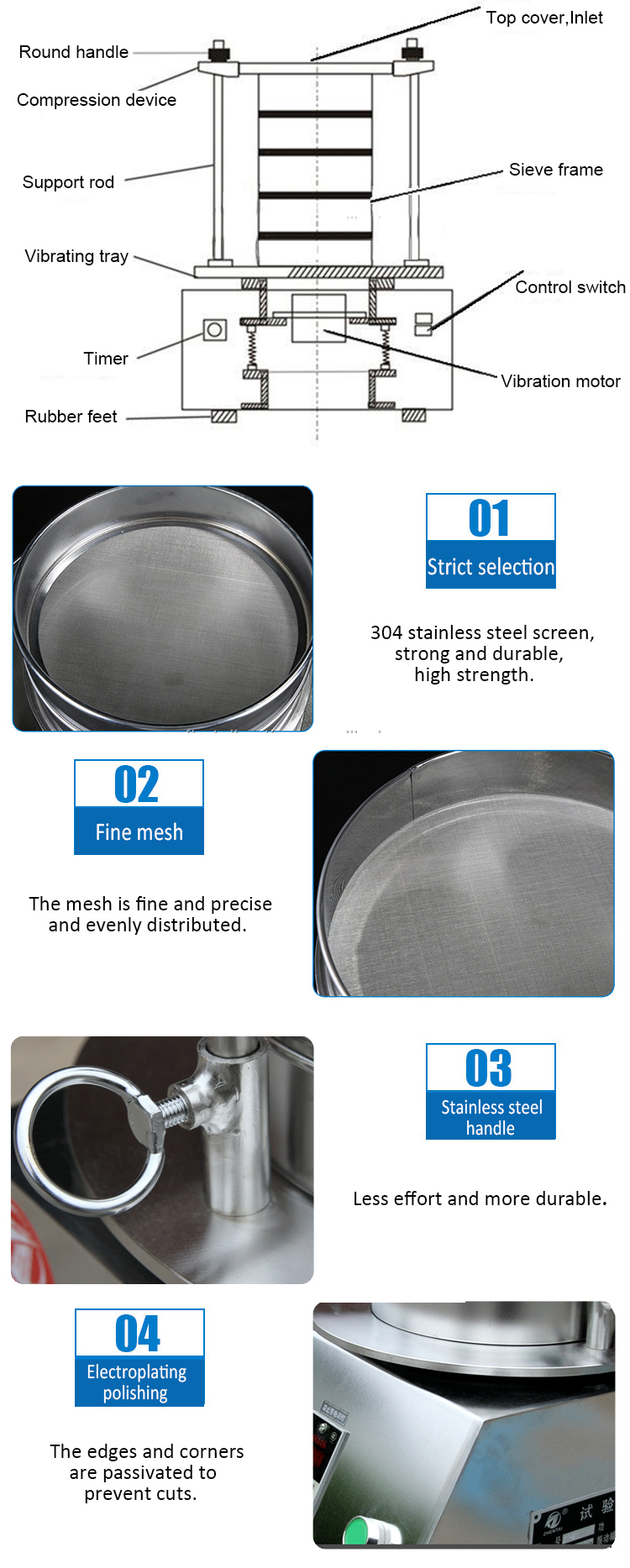

An electromagnetic sieve shaker typically consists of the following components:

Base unit: The base unit is the main part of the sieve shaker, which houses the electromagnetic drive and the digital controller.

Sieve stack: The sieve stack is a set of wire mesh sieves that are stacked on top of each other in decreasing order of mesh size. The sample to be analyzed is placed on the top sieve, and the sieves are secured in place using a clamping system.

Electromagnetic drive: The electromagnetic drive generates a controlled vibration that is transmitted to the sieve stack. The amplitude and frequency of the vibration can be controlled using the digital controller.

Digital controller: The digital controller allows for precise control over the sieving process. It features a digital timer, amplitude controller, and other settings that can be adjusted to meet the specific requirements of the particle size analysis.

Clamping system: The clamping system holds the sieve stack in place and ensures that the sieves remain securely in place during the sieving process.

Power supply: The electromagnetic sieve shaker is powered by an electrical source, which is typically a standard AC power outlet.

The Electromagnetic sieve shaker uses 3-D throwing motion to ensure optimal use of the sieve area and allow the sample to move evenly across the entire sieve surface. It can be used for separation and particle size determination of powders, granules or suspensions, and can be dry sieved to 5 microns.

Application examples: cement clinker, chemicals, coffee, building materials, fertilizers, fillers, flour, grains, metal powders, minerals, nuts, plastics, sand, seeds, soil, washing powder,...

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio molitor eggs | 12 mesh |

| Worm dung | 30 mesh | Soybeans | 4-5 mesh | green beans | 10 mesh |

| Rice | 12-14 mesh | rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| flour | 50-60 mesh | Miscellaneous grains | 40-50 mesh | Sesame Millet | 22-24 mesh |

| Fried Chicken Burger Breaded | 20-30 mesh | Mung bean flour | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Traditional Chinese Medicine Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Medicine residue | 60-150 mesh | Soy milk | 80-120 mesh | honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.