For inspection of your product, ideal for screening incoming materials and final production inspection of finished powders

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Power: 0.18-2.22KW

Application:Starch, traditional Chinese medicine powder, peanut, sesame, wheat, mature vinegar, soybean milk, fruit juice, animal fat, etc.

Commitment:

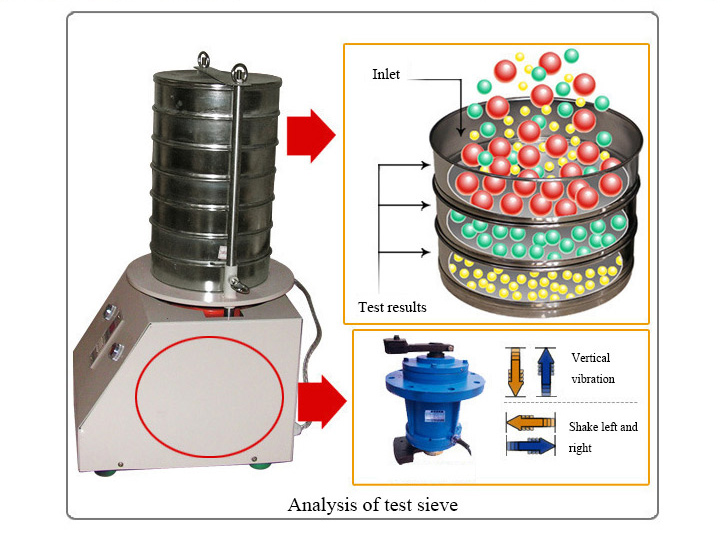

Sieve shaker machine is used in the laboratory to analyze the particle size structure of granular and powdery materials. It is widely used in laboratory sampling and testing. It can accurately separate 2-8 particle segments from a granular material at the same time. It can also be used to analyze slurry Fineness and impurity content. The working time of the laboratory test sieve is controllable and the machine stops automatically, which ensures the repeatability of the test, comprehensive functions and convenient operation.

Advantages:

Precise screening: It is driven by a vibration motor to generate high-frequency vibration, so that the material jumps on the screen to achieve precise screening. The screening accuracy can reach 0.025~3mm.

Multi-stage screening: The sieve shaker machine can set up multiple layers of screens as needed to achieve multi-stage screening of the material, and can accurately separate 8 particle segments at the same time.

Corrosion and high temperature resistance: The sieve shaker machine is made of polished stainless steel, resistant to acid and alkali corrosion, resistant to high temperatures below 300℃, non-magnetic, and not easy to rust.

Easy to move: The sieve shaker machine is small in size, light in weight, easy to move, and suitable for screening operations in various places.

Platform operation, no need to fix: The sieve shaker machine adopts platform operation, no need to fix, which is convenient for operators to operate and maintain.

Low noise: The sieve shaker machine adopts a special shock-absorbing design, low noise, and will not cause noise pollution to the surrounding environment.

Disadvantages:

In addition to the advantages, the sieve shaker machine also has some disadvantages:

Limited processing capacity: The sieve shaker machine is suitable for processing a small amount of material. If you need to process a large amount of material, you need to choose other types of screening equipment, such as drum screens, spiral screens, etc.

Easy to clog: When the material is more viscous or has a high water content, it is easy to clog on the screen.

Inconvenient to replace the screen: Replacing the screen requires disassembling some parts, which is relatively troublesome to operate.

Sieve shaker machine uses YZU vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits the vibration through the vibrating plate to the screen frame on the upper part of the vibrating plate. The material particles smaller than the aperture of the screen are sieved to the lower screen frame, so that only materials of the same particle size are left in each screen frame to achieve the separation of different particle sizes and determine the particle size composition of the material, so that the size of the material in the screen frame The materials can be very effective for filtering, grading and screening purposes.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Sieve shaker machine is widely used in the inspection and analysis of food, medicine, chemical industry, abrasives, pigments, mining, metallurgy, geology, ceramics, national defense and other industries in scientific research units, laboratories, inspection rooms, production control, etc.

The following will introduce its application scenarios in some industries in detail:

Food industry

Raw material pretreatment: Screening of raw materials such as grains, beans, nuts, fruits, etc., to remove impurities and separate large and small particles.

Product quality control: Screening of finished food products to ensure that the product particle size is uniform and meets quality standards, such as screening flour, powdered sugar, milk powder, etc.

Production process control: Screening of powdered and granular materials during the production process, such as screening flour, powdered sugar, milk powder, etc.

Pharmaceutical industry

Raw material pretreatment: Screening of medicinal materials, powders, tablets, etc. to remove impurities.

Production process control: Screening of powdered and granular materials during the production of medicines, such as screening of powdered and granular materials.

Pharmaceutical inspection: Screening of medicines to inspect the particle size distribution of medicines.

Chemical industry

Raw material pretreatment: Screening of various chemical raw materials to remove impurities and ensure the purity of raw materials.

Production process control: Screening of powdered and granular materials during the chemical production process, such as screening of catalysts, dyes, pigments, etc.

Product quality control: Screening of chemical products and inspection of product particle size distribution.

Metallurgical industry

Metal powder classification: Screening of metal powders and classification according to particle size, used in metal powder metallurgy, spraying and other industries.

Metal particle classification: Screening of metal particles and classification according to particle size, used in metal processing, casting and other industries.

The price of Dahan Sieve Shaker Machine is generally: $800.00-$4,500.00/Set.

The price of sieve shaker machine is affected by many factors, including the number of screen layers, screen material, motor power, manufacturer, brand awareness, etc. Generally speaking, the price of sieve shaker machine with single-layer screen is relatively low, ranging from several thousand yuan to tens of thousands of yuan; the price of sieve shaker machine with multi-layer screen is higher, ranging from tens of thousands of yuan to more than 100,000 yuan.

The main factors affecting the price of sieve shaker machine:

Number of screen layers: the more layers, the higher the price.

Screen material: The price of stainless steel is higher than that of ordinary steel.

Motor power: The greater the power, the higher the price.

Brand awareness: The higher the brand awareness, the higher the price.

It is recommended that you choose the appropriate sieve shaker machine according to your actual needs, compare the price and performance, and choose the most cost-effective equipment.

Xinxiang Dahan Factory is a professional manufacturer of sieve shaker machines with many years of production experience and strong technical strength. The manufacturer has a complete range of products, covering sieve shaker machines of various specifications and models to meet the needs of different users. The sieve shaker machines produced by Dahan are famous for their high efficiency, low energy consumption, and strong durability. They are widely used in food, medicine, chemical industry, mining and other industries. The manufacturer has advanced production equipment and perfect testing methods to ensure stable and reliable product quality. In addition, Dahan Factory also provides professional after-sales service, providing customers with all-round technical support and solving various problems encountered by customers during use.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.