Conveying equipment that can be easily carried and moved, usually used for temporary or short-distance material transportation needs on site.

![]()

![]()

Price:$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Belt width: 500/650/800/1000mm

Conveying length: 10-25 meters

Conveying capacity: 50-550m³/h

Conveying speed: 0.8-2.0 m/s

Lifting Height:adjustable

Application: It is widely used in construction sites, mining sites, grain storage and other occasions. It is suitable for transporting soil, sand, coal, grain, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

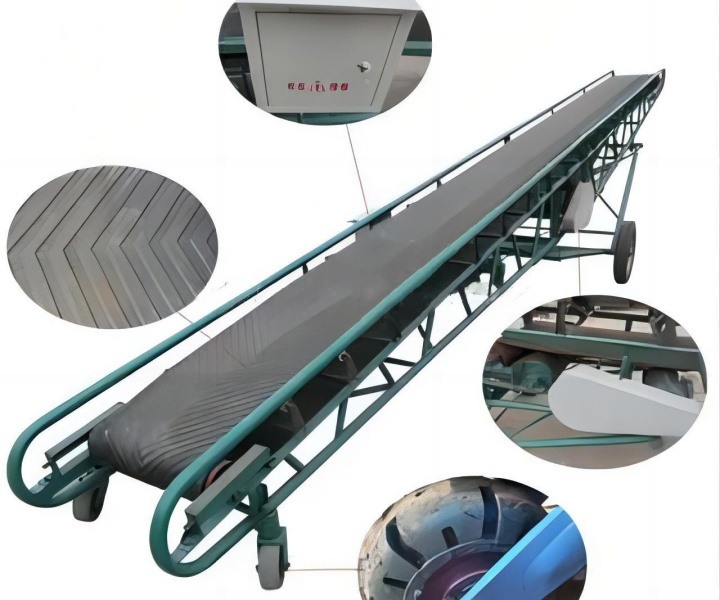

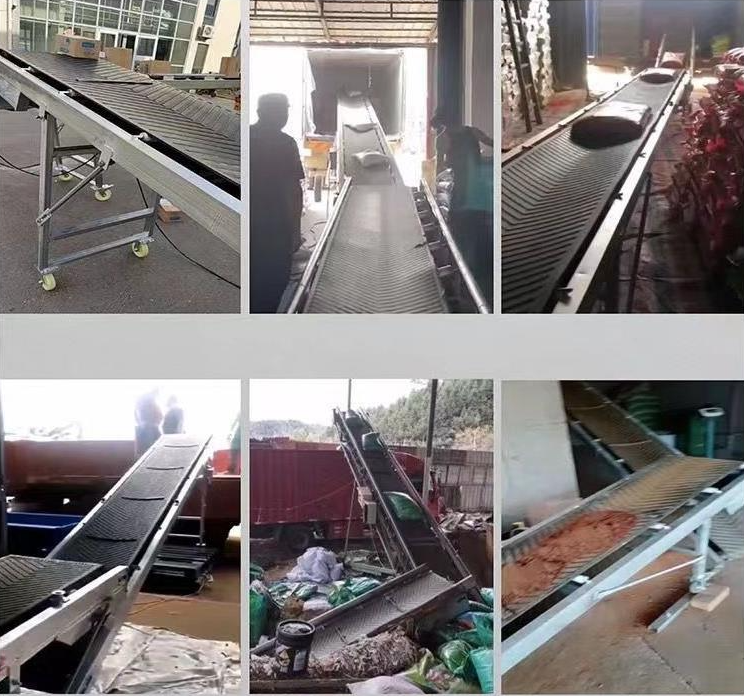

Portable belt conveyor is a mobile and flexible material handling system that uses a continuous belt to transport items or bulk materials from one location to another. It is designed to be easily transported, assembled, and disassembled, making it ideal for temporary or mobile applications.

Portable belt conveyors offer several advantages, including flexibility, mobility, and ease of setup. They are commonly used in applications such as construction sites, warehouses, loading docks, and temporary material handling operations. These conveyors provide a convenient and efficient solution for transporting items or bulk materials across different locations, making them a versatile tool in various industries.

Portable belt conveyors find applications in numerous industries and scenarios where flexibility, mobility, and temporary material handling solutions are required. Here are some common applications:

Construction site: Conveying materials such as aggregate, sand, gravel, concrete and construction waste. They efficiently move materials from one location to another, allowing easy loading and unloading of goods onto trucks, dumpsters or other equipment.

Warehousing and Logistics: They facilitate the loading and unloading of products to trucks, trailers or storage areas, increasing efficiency and reducing manual labor.

Mining and Quarrying: For transporting bulk materials, ores, minerals and aggregates. They can be easily relocated as the mine progresses, enabling efficient material transfer and ensuring flexibility to changing operational requirements.

Agriculture: For tasks such as loading/unloading grain, seed, fertilizer or animal feed. They efficiently handle bulk materials and facilitate their movement to storage areas, trucks or processing equipment.

Temporary loading and unloading: used for temporary locations where materials or products need to be loaded and unloaded. This includes scenarios such as temporary work locations, remote locations or areas with limited infrastructure.

The working principle of a portable belt conveyor is based on the movement of a continuous belt, carrying materials or items from one end to the other. The following is a brief introduction to the working principle:

Loading: Portable belt conveyors are equipped with loading points, which can be hoppers or openings designed for controlled material or item input. Load points allow materials or items to be placed on the conveyor belt, starting the transfer process.

Conveying: Once materials or items are loaded onto the conveyor belt, they are conveyed along the length of the conveyor belt by the continuous motion of the conveyor belt. The belt moves in a specific direction, usually driven by a motorized pulley or drive, to push material or items toward the discharge end of the conveyor.

Discharge: At the discharge end of a portable belt conveyor, there may be discharge spouts, chutes, or specific areas for transferring or collecting materials or items. The continuous motion of the belt facilitates the control and regulation of the discharge of the conveyed material or item at designated points.

Portability

for easy transport between different work areas or job sites. They are usually lightweight, compact and can be installed and removed quickly. They can be folded or disassembled into smaller components for easy transport and storage.

Adjustable length and height

It has adjustable length and height to meet different conveying requirements. The length of the conveyor can be extended or shortened to suit the distance between loading and unloading points. The height of the conveyor can be adjusted to match the height of the material source or receiving equipment.

Durable Construction

Although portable belt conveyors are lightweight and mobile, they are constructed to withstand the rigors of handling different materials. They are usually made of durable materials like aluminum or steel, and have a strong frame and conveyor belts that can handle a variety of loads.

Safety function

The portable belt conveyor is equipped with safety function to ensure the safety of the operator and equipment. These may include emergency stop buttons, safety guards and limit switches to prevent accidental operation or injury.

| Model | Belt Width (mm) | Lenth(m) | Belt Speed (m/s) | Lifting Height | Slope Angle | Capacity (m³/h) |

| DY-500 | 500 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 50-140 |

| DY-650 | 650 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 100-250 |

| DY-800 | 800 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 170-350 |

| DY-1000 | 1000 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 270-550 |

Here are some key features and components of a portable belt conveyor:

Belt: It is usually made of a durable material such as rubber, PVC or fabric and forms a continuous loop that runs along the length of the conveyor.

Frame and Support: Frames are usually made of lightweight materials like aluminum or steel, ensuring durability and portability. It is designed for easy assembly and disassembly, and can be quickly installed in different positions.

Adjustable Length and Height: Portable belt conveyors often have adjustable length and height to suit various applications and requirements. The length of the conveyor can be extended or reduced by adding or removing sections, allowing flexibility in positioning and conveying distance. The height of the conveyor can be adjusted to match specific loading and unloading points.

Wheels and Handle: The portable belt conveyor is equipped with wheels and handle for easy transportation. The wheels are usually lockable for easy moving and positioning of the conveyor. The handles provide the operator with a means to maneuver and steer the conveyor when required.

Control and safety features: They may include features such as emergency stop buttons, safety guards, and limit switches to keep operators safe and prevent accidents.

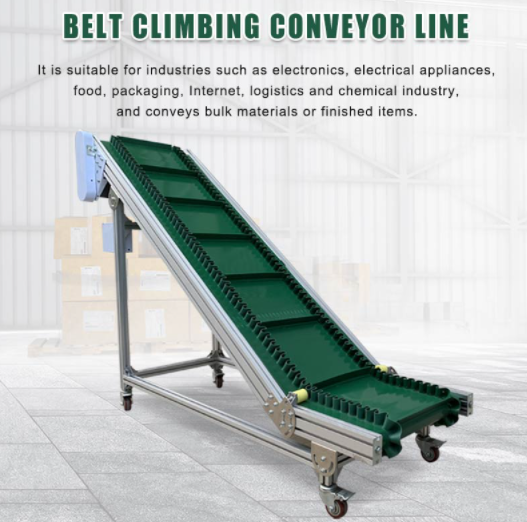

Portable belt conveyors can be divided into the following two categories:

|

|

|

| Features | This type of portable belt conveyor can be unfolded when in use to provide conveying functions; it can be folded up when not in use for easy handling and storage. | With a retractable design, the length can be adjusted as needed to adapt to the material transportation needs of different sites. This design makes it more flexible and suitable for conveying distances of different lengths. |

Xinxiang Dahan is a manufacturer specializing in the production of portable belt conveyors and is committed to providing customers with high-quality conveying equipment solutions. Xinxiang Dahan portable belt conveyor is flexible, portable, efficient and economical, and is widely used in construction sites, mining sites and other fields.

The portable belt conveyors produced by our factory mainly include various models such as 500mm, 650mm, 800mm, 1000mm in width, the lifting height is adjustable, the length can reach 25m, and the conveying capacity of materials is large. All products are assembled and delivered by the manufacturer to ensure that the user can put into production after receiving the goods. In addition, our factory can accept customer's "tailor-made" equipment to meet the user's material screening needs to the greatest extent.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.