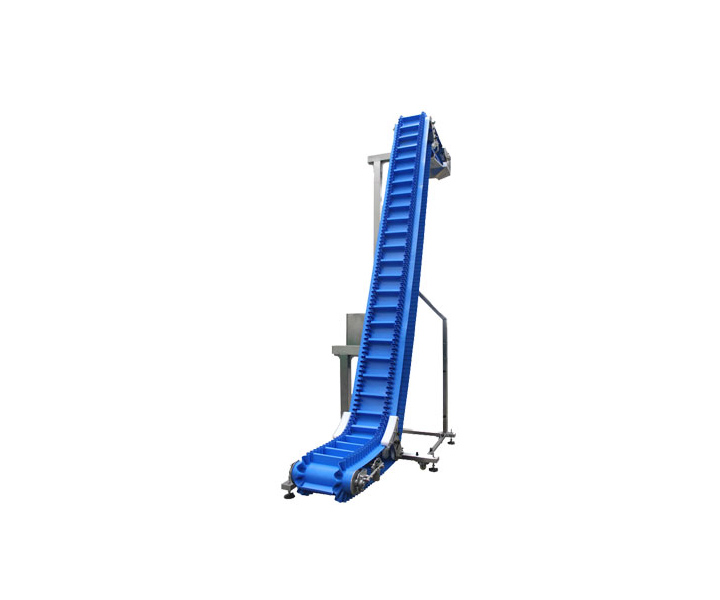

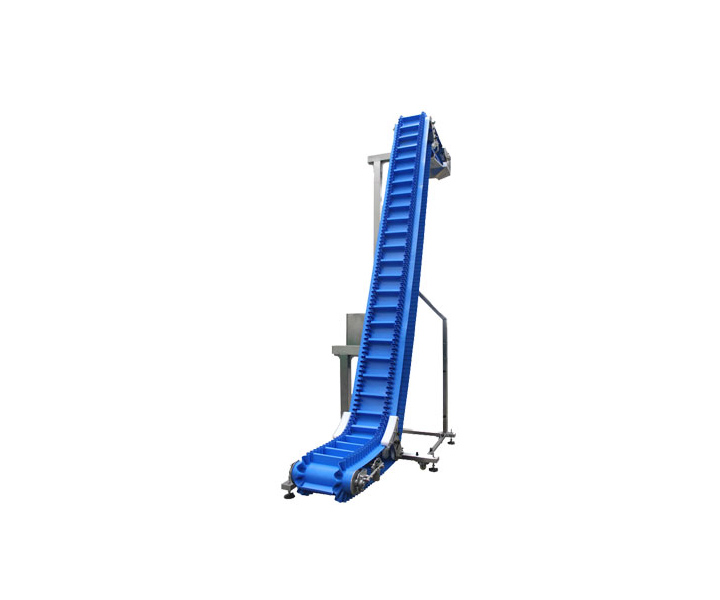

Climbing belt conveyor

Climbing belt conveyor Vertical climbing belt conveyor

Vertical climbing belt conveyor Adjustable Speed climbing belt conveyor

Adjustable Speed climbing belt conveyor Mobile climbing belt conveyor

Mobile climbing belt conveyor Food climbing belt conveyor

Food climbing belt conveyor

Suitable for continuous conveying of goods between floors or height differences

![]()

![]()

![]()

Price:$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Climbing angle: 0°-90°

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying speed: 1.25-2m/s

Conveying length: 10 meters

Belt material: PVC/PU rubber

Frame Material: Carbon Steel/Stainless Steel

Application: The material can be transported from the initial feeding point to the unloading point inclined or vertically, used in chemical, electronic, food processing and other industries

Commitment:

Climbing belt conveyor is suitable for the continuous conveying of goods between floors or height differences. The climbing angle is 0-90°. It can transport the products from the initial feeding point to the unloading point. The belt is equipped with diaphragms and skirts. This enables the product to be lifted and conveyed at a larger angle without the product falling.

Climbing belt conveyor allows feeding control at one or more positions, and can be easily connected with various types of feeding equipment. The feeding point is equipped with a vibrating feeder, which can continuously and evenly send the product to the receiving port.

The angle of the climbing conveyor belt can be more than 30 degrees, or even 90 degrees for vertical conveying. Different from ordinary belt conveyors, the climbing belt conveyor adopts corrugated sidewall belts, and a diaphragm is added in the middle to prevent products from climbing. fall during the process.

Climbing belt conveyor is used for feeding and climbing conveying of various materials, and the conveying angle is 30°-90°, suitable for food, agriculture, medicine, chemical and other industries to lift materials from the ground to the top, such as snack food, frozen food , vegetables, fruits, candy, chemicals or other granular products, etc.

The conveyor belt forms an endless belt through the electric drum and the reversing drum of the climbing belt conveyor, which is driven by the motor and the reducer to generate power, and relies on the frictional force generated between the conveyor belt and the electric drum to transport the material. The discharge end of the slope belt conveyor can increase the effective traction force and avoid the inability to effectively convey materials during the conveying process.

Inclined/large angle conveying

Conveyor belts with corrugated rib and diaphragm are especially suitable for conveying at large inclination angles, and the conveying angle is in the range of 30°-90°.

High conveying efficiency

The common width of the belt is: 20 ~ 2000mm, and it can also be customized according to customer requirements, the length can reach 10 meters, and the conveying height can reach 4 meters.

Adjustable conveying speed

The conveying speed is generally: 0.1 ~ 10M/min; the speed can also be adjusted or fixed according to user needs.

Automation

It can be combined with other conveying equipment to form a horizontal or inclined conveying system to meet the needs of different layout types of operation lines.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | >15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

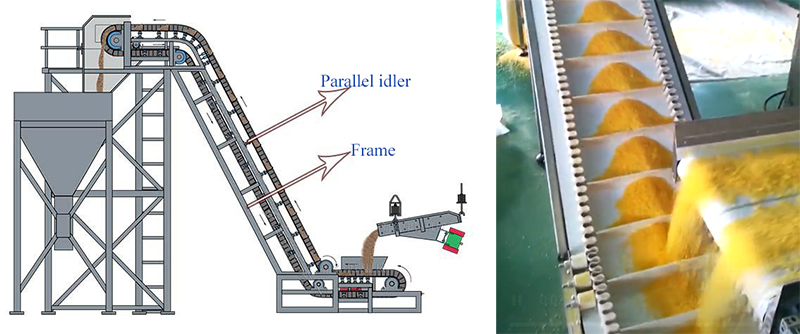

The climbing belt conveyor is mainly composed of a driving device, a transmission roller, a redirecting roller, a corrugated sidewall conveyor belt, a pinch pulley, an idler, an idler belt, a tensioning device, a frame and so on.

Belt material: PP plastic module belt, PVC green belt, PVC baffle belt or PU belt. In addition to ordinary materials, it can also transport special materials such as oil resistance, corrosion resistance and antistatic. The use of food-grade special conveyor belt can meet the needs of food, medicine, daily chemical and other industries.

Control box: high-quality 304 stainless steel electric box, simple design, easy to operate, frequency converter to control the speed.

Vibration feeding hopper: 304 stainless steel vibrating hopper, 150L, can evenly feed the product into the receiving port, we can also make its size and volume according to your needs, and the vibration frequency can also be adjusted.

Drive mode: gear motor drive, electric drum drive, etc.

Speed regulation mode: frequency conversion speed regulation, stepless speed change, etc.

Frame Material: Stainless Steel, Carbon Steel, Aluminum.

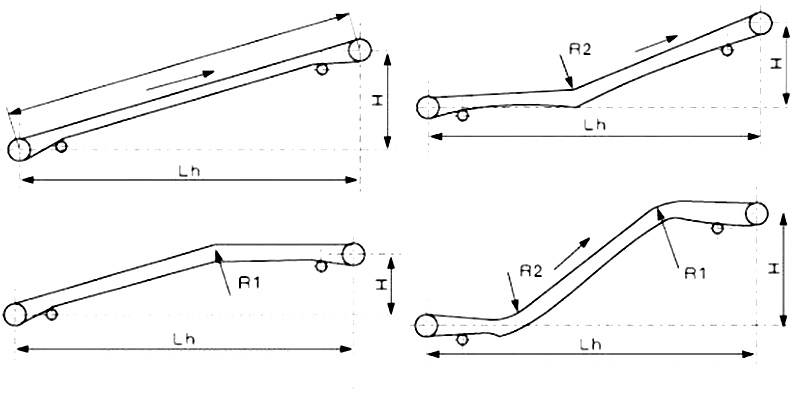

There are various arrangements of climbing belt conveyors. The commonly used construction method is the Z-shaped construction method, which is mainly composed of upper horizontal section, inclined section and lower horizontal section.

The lower horizontal section is generally built with low-type intermediate frame legs, and the lower horizontal section is used for smooth feeding during material loading, reducing the pressure on the conveyor during loading, and reducing material scattering.

The inclined section is the main conveying section of the climbing belt conveyor. The inclined section differs depending on the angle of the intermediate frame legs. If the angle is lower than 45°, you can use the low-type intermediate frame legs. If the angle is higher than 45°, you need to use the type II low-type intermediate frame. Intermediate frame legs.

The upper horizontal section is the discharge end. According to the discharge requirements of different heights, the height of the head frame used is different, and the legs of the intermediate frame should be matched according to the head frame. For example, the low-type convex arc section frame is equipped with low-type intermediate frame legs. (The height of the head frame is H0=1000mm); the Chinese-style convex arc section frame is equipped with Chinese-style intermediate frame legs (the head frame height is H0=1100~1500mm); the high-type convex arc section frame is equipped with high-type intermediate frame legs (Head frame height is 1600~2000mm). The material can be smoothly transitioned through the convex arc section to reduce the loss of the climbing belt conveyor.

Xinxiang Dahan climbing belt conveyor manufacturers have a full range of product models. They are mainly used in many industries such as food, medicine, chemical industry, building materials, metallurgy, and coal. Or vertically arranged to meet more user needs. Factory direct sales, cheap price, can save 30% to 40% of the cost, the equipment is guaranteed for 1 year, and the maintenance is free during the warranty period.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.