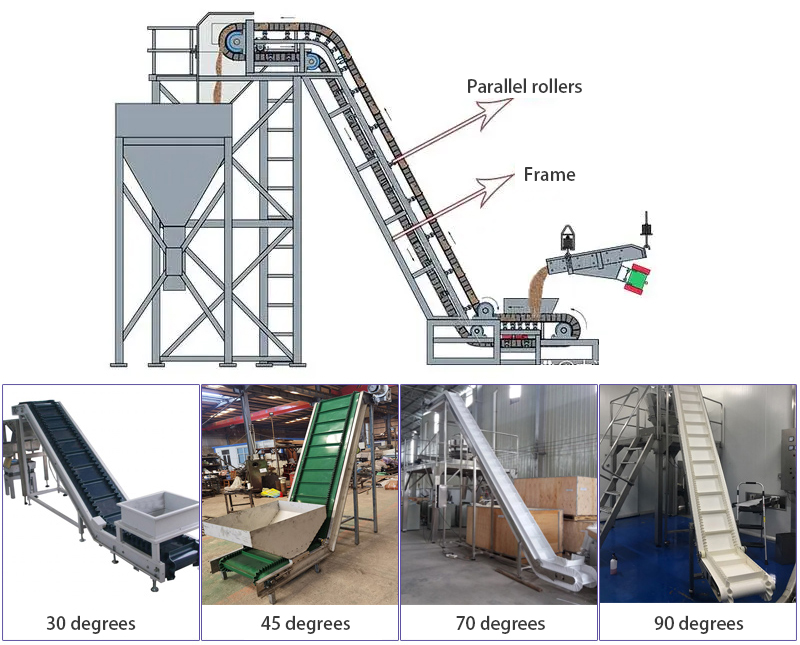

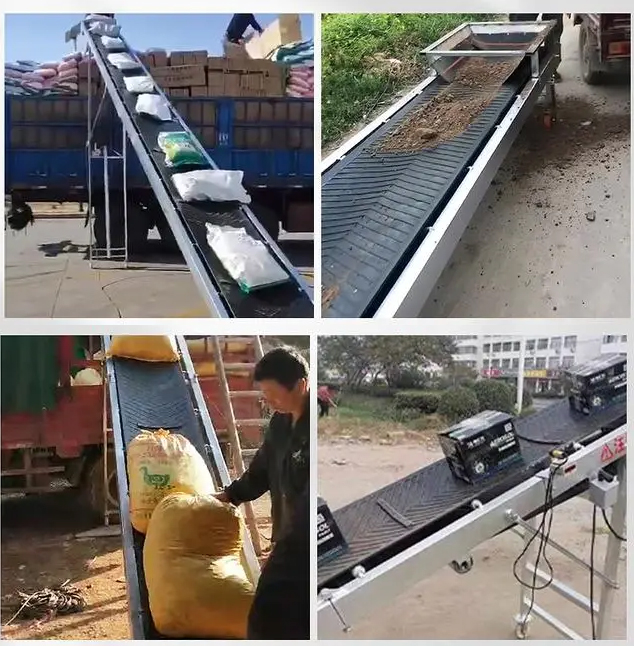

Safely transport products to higher levels at an angle

![]()

![]()

![]()

Price:$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Belt Width: 500-1800mm

Height of Sidewall: 80-500mm

Belt Speed: 0.8-4.0m/s

Angle of Inclination: 30-90 degrees

Capacity: 84-5036m³/h

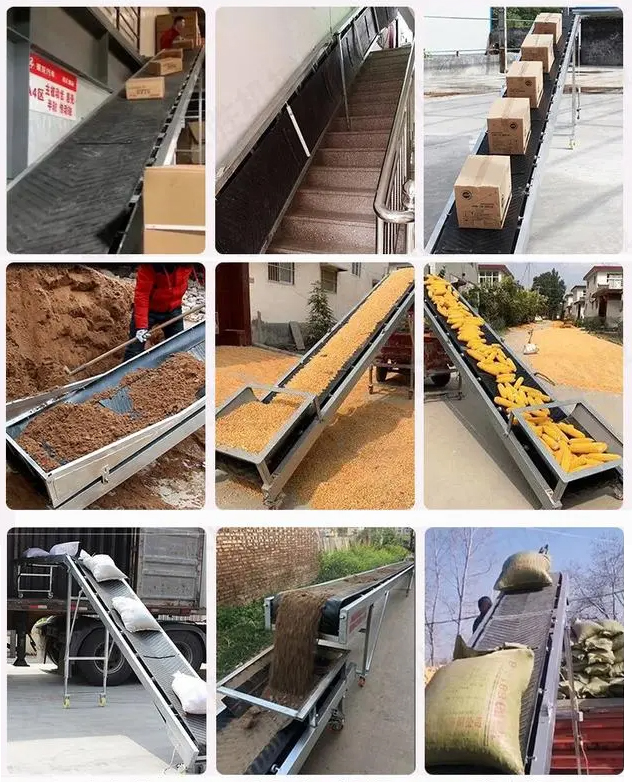

Application: It can effectively transport products from low to high, and is widely used in the food packaging industry, as well as the food industry, warehousing and logistics industry, packaging industry, express delivery industry, electronic and electrical industry, medicine and other industries.

Commitment:

Inclined belt conveyor, also known as an incline conveyor or inclined conveyor, is a type of conveyor system designed to transport materials at an inclined angle. Unlike horizontal belt conveyors that move materials on a flat surface, inclined belt conveyors are configured with an inclined or sloped belt to elevate materials to a higher level or descend them to a lower level.

Inclined belt conveyor adopts corrugated sidewall conveyor belt (that is, the design of corrugated sidewall and partition plate), the advantage of this is that when encountering the inclination angle, the corrugated sidewall and the partition plate form an independent box-type bucket. The material can be framed so that it does not fall off during transportation.

In general, for traditional flat belts without skid plates or scrapers, it is common to use slope angles as high as 18-20 degrees. However, for specific applications and using cleats or baffles, higher tilt angles can be achieved, up to a maximum angle of 90 degrees. There is no universally fixed maximum angle for all belt conveyors as it will vary based on these factors. However, there are some general guidelines that can help determine the maximum angle for a belt conveyor:

Belt types and characteristics: Different belt materials, such as rubber, PVC or fabric, have different coefficients of friction and grip characteristics. In addition, the flexibility, tensile strength and thickness of a conveyor belt can also affect its ability to handle inclines.

Material being conveyed: Bulk materials with a high coefficient of friction, viscous or large particle sizes may require lower inclination angles to prevent slippage or material flow problems. On the other hand, free-flowing material may allow for steeper inclines.

Environmental Factors: Wet or slippery conditions may require a smaller tilt angle to maintain stability and prevent spillage of material.

Inclined belt conveyors work on the principle that a continuous belt moves along an incline or slope, conveying material from one end to the other. Here's a step-by-step explanation of how it works:

Inclined Angle: The conveyor is set at an inclined angle, which can range from a slight incline to a steep slope, depending on the application and the material being transported.

Material Loading: Loading of material to be transported onto the lower end of the conveyor, usually by manual or mechanical means such as loading chutes or conveyor hoppers.

Belt Movement: When the motor rotates the head pulley, the belt starts to move. Friction between the belt and pulleys and the weight of the material being conveyed cause the belt to grip and move along the inclined surface.

Material conveying: The inclined belt conveyor conveys the material along the slope. Cleats or scrapers, if present, help prevent material from slipping or rolling back on inclined surfaces, ensuring reliable and stable transport.

Unloading: At the upper end of the conveyor, material is unloaded directly into another conveyor, processing equipment or storage bins, depending on the application.

Inclined belt conveyors are widely used in various industries that require inclined or vertical conveying of materials. Here are some common applications for inclined belt conveyors:

Mining and Quarrying: Conveying bulk materials such as ore, coal, gravel or aggregates from lower levels to higher levels and vice versa. They are used for efficient material transfer between different levels of mine or quarry, including loading and unloading trucks or storage boxes.

Agriculture: For tasks such as loading and unloading crops, grain, seeds or fertilizers. They can transport materials from the ground to high-bay storage bins, processing equipment or trucks for distribution.

Manufacturing and Production: Efficient material handling at different heights. They transport raw materials, intermediate or finished products between various stages of the production process, such as feeders, assembly lines or packaging stations.

Food Processing: They transport items such as fruit, vegetables, meat, baked goods or packaged food between processing plants, sorting stations or between different levels of production facilities.

Warehousing and logistics: used in warehouses and logistics centers for overhead material transport. They can move goods between or on different floors of a facility, facilitating efficient storage, order picking and loading and unloading operations.

Construction sites: For vertical or inclined movement of construction materials. They can transport aggregate, sand, cement or other construction materials to higher heights, such as scaffolding or elevated storage areas.

Ports and terminals: Used for loading and unloading cargo onto ships or barges. They transport material from the ground to the vessel's elevated platform, allowing for efficient and safe transport during offshore operations.

Large inclination conveying

It is suitable for inclined or vertical conveying, and the conveying angle can reach 90 degrees.

The product is not easy to slip

Corrugated ribs and diaphragms are added to prevent the product from falling off easily when conveying at a large angle.

Can be combined into conveying system

It can be used with other conveying equipment according to the conveying site, or assembled with multiple machines to form an automatic conveying system, which improves conveying efficiency and reduces input costs.

Customizable

The hopper can be fed in the horizontal section to avoid material flying powder when feeding, or it can be designed as a mobile type according to the requirements, which is convenient for moving between factories.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Inclined Belt: The conveyor belt is designed with an incline, typically ranging from a few degrees to steep angles, depending on the application. The angle of inclination determines the rate of ascent or descent of the materials.

Cleats or Flights: Inclined belt conveyors often have cleats or flights attached to the belt surface. These raised sections prevent materials from sliding back or slipping during transportation on the inclined surface.

Drive System: Inclined belt conveyors are equipped with a drive system, typically located at the lower end of the conveyor, which provides the necessary power to move the belt and transport materials uphill or downhill.

Calculating the power requirements for an inclined belt conveyor involves considering several factors, including the weight of the conveyed material, the angle of inclination, the conveyor length, the belt speed, and the friction between the belt and the pulleys. Here is a general approach to calculating the power required for an inclined belt conveyor:

1.Determine the Belt Tension: The first step is to calculate the belt tension required to convey the material. The belt tension is influenced by the weight of the material being transported, the angle of inclination, and any additional forces such as acceleration or deceleration. Use the following formula to calculate the belt tension (T):

T = (W + H) × L × K

Where:

W = Weight of the material being conveyed per unit length (lbs/ft or kg/m)

H = Vertical height or lift (ft or m)

L = Conveyor length (ft or m)

K = Belt factor (accounts for the angle of inclination and other factors)

The belt factor (K) is typically obtained from conveyor design standards or can be determined based on the specific application.

2.Calculate the Frictional Resistance: The power requirement is influenced by the friction between the belt and the pulleys. The frictional resistance can be estimated using the following formula:

Frictional Resistance = (T × V) / 33,000

Where:

T = Belt tension (lbs or N)

V = Belt speed (ft/min or m/s)

The frictional resistance is expressed in horsepower (HP) or kilowatts (kW).

3.Calculate the Total Power Requirement: The total power requirement for the inclined belt conveyor includes the power required to overcome the frictional resistance and any additional power required for the drive system. The additional power required depends on factors such as the efficiency of the drive system and any losses in the transmission.

Total Power Requirement = Frictional Resistance + Additional Power.

The additional power can be estimated based on the specific drive system being used.

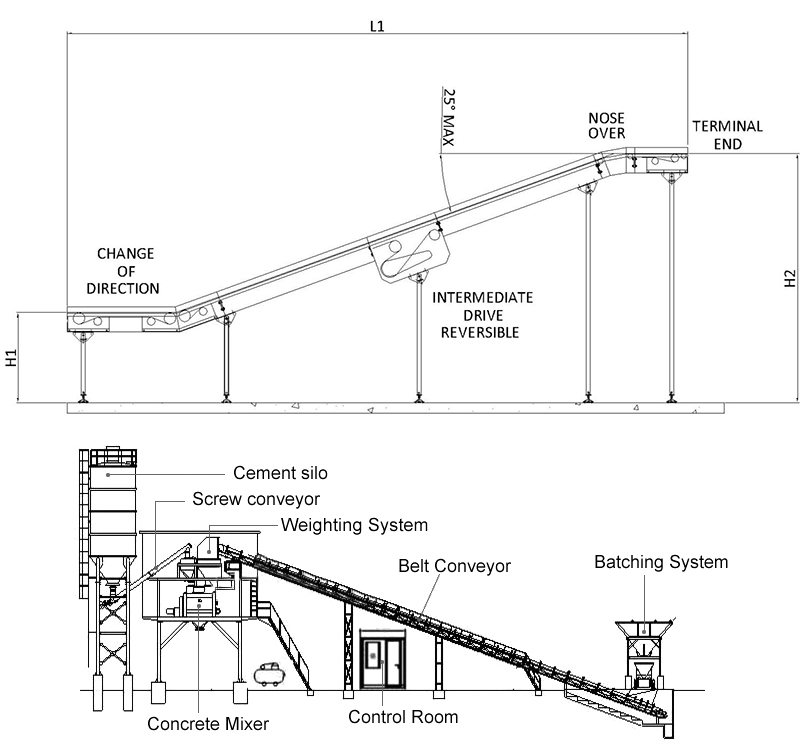

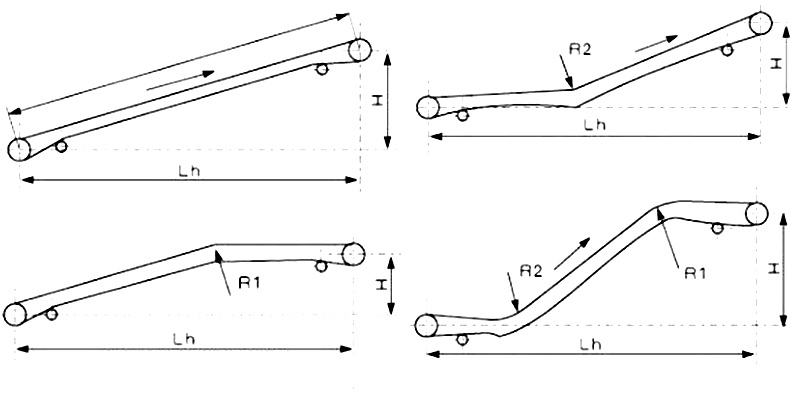

In order to obtain better material receiving and unloading conditions, the large-inclination belt conveyor adopts a "Z" shape arrangement. That is to say, there are upper horizontal section, lower horizontal section and inclined section, and materials are received in the lower horizontal section and unloaded in the upper horizontal section. The upper horizontal section and the inclined section are connected by a convex arc section frame, and the lower horizontal section and the inclined section are connected by a concave arc section frame to realize a smooth transition of the conveyor belt.

1. Upper horizontal section: In order to meet the requirements of different unloading heights, the head frame is divided into lower head frame, Chinese type head frame and high type head frame. Correspondingly, the upper horizontal section is equipped with a low-type convex arc section frame and a low-type middle frame support leg, a Chinese-style convex-arc section frame and a Chinese-style intermediate frame support leg, a high-type convex arc section frame and a high-type intermediate frame support leg.

2. Inclined section: Regardless of whether the upper horizontal section adopts low-type, middle-type, or high-type intermediate frame legs, the inclined section adopts low-type intermediate frame outriggers. When the inclination angle of the conveyor is R45°, it is recommended to use Type II low-type intermediate frame legs.

3. Lower horizontal section: The lower horizontal section adopts low-type middle frame outriggers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.