Gas ultrasonic protection sieving machine is another ultrasonic sieving machine that uses the principle of gas sealing. It is equipped with a gas protection device on the basis of the ultrasonic sieving machine. It is installed for the characteristics of certain materials, such as some materials cannot be touched. Oxygen, carbon dioxide, 3D printing powder, metal powder, graphite powder, etc., are protected by inert gas during the screening process, which can prevent the powder from oxidizing or deteriorating due to moisture absorption. Due to the sealing design, it can also prevent the dust from being too dense and exposed to the air. cause an explosion.

The Gas ultrasonic protection sieving machine is designed in a fully enclosed form and is equipped with a special inflatable device to ensure that the new material does not touch the air and equipment material during the screening process, so as to achieve high-efficiency screening and do not change the properties of the material. The equipment can be widely used For alloy powder, titanium alloy, stainless steel powder, 3D printing powder, metal powder, graphite powder, etc.

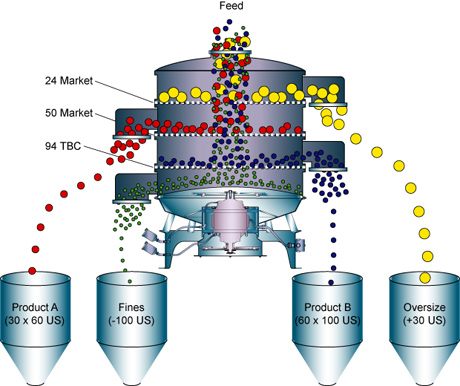

Gas ultrasonic protection sieving machine is composed of 304 stainless steel material, gas protection hose, anti-static device and other structures. Using the relative motion of the granular material and the sieve surface, some particles pass through the sieve holes, and the material is divided into different levels of sieving machine according to the particle size. The sieving process of the sieving machine is generally continuous. After the sieving raw materials are fed to the sieving machine (referred to as the sieve), the material smaller than the sieve hole size passes through the sieve hole, which is called the under-sieve product; the material larger than the sieve hole size is The sieve surface is continuously discharged, which is called the product on the sieve.

1. The use of inert gas protection can prevent powder oxidation or moisture absorption and deterioration.

2. It is suitable for sieving from 36 microns to 25 mm. Use ultrasonic frequency to vibrate the grid. This keeps the hole from clogging.

3. Use customized layered screens and powerful 3D vibration motion to screen products through different screens, which can continuously filter up to 5 levels of product separation in just 1 operation.

4. Various sizes are available, suitable for smaller and larger scale operations from Ø900 to Ø2200, It permits a production volume of 100 to 5,000 kg/h, depending on the product.

5. The sealing structure prevents dust from overflowing and improves the operating environment.

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

Gas ultrasonic protection sieving machine sieving to 500 mesh or 0.028mm, filtration to 5 microns, grading screening, 1 to 5 layers of sieves can be selected, 2-6 grades of sorting can be performed at the same time, suitable for screening metals Particles, metal powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, 3D printing materials, graphite powder, carbon dioxide and other materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.