The ultrasonic sieving machine can easily solve the mesh blockage and improve the screening output and precision. ultrasonic sieving machineing machine has been successfully applied to the screening and classification of 400 mesh, 500 mesh and 600 mesh ultrafine materials. The ultrasonic sieving machine has a wide range of applications. What are its advantages? Listed below are 5 points.

Ultrasonic sieving machine adds ultrasonic deblinding system, which applies high frequency, very low amplitude vibration to the screen, which helps to deblind and fluidize fine products, making it easier to screen, on screens as fine as 20 microns Screens powders without clogging or clogging, providing better screening for all kinds of powders, especially sticky and difficult powders.

Sieving graphite powder

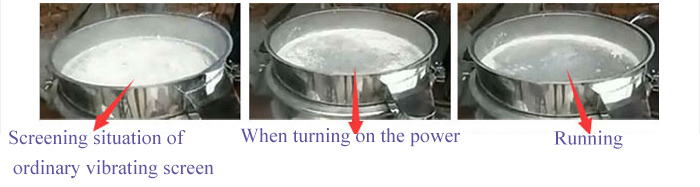

The screen frame is operated in three dimensions under the action of the vibrating motor and at the same time is subjected to a high-frequency and low-amplitude ultrasonic vibration wave from the transducer, so that the material is suspended on the screen surface at a low altitude, thereby effectively solving the problem of material blocking the network.

Ultrasonic sieving can make the powder pass through the sieve holes faster, thereby increasing the sieving capacity by 10 times.The table below is the comparison of the screening effect between the ultrasonic sieving machine and the ordinary sieving machine.

| Model (mm) |

Testing materials | Ordinary sieving machine | UItrasonic sieving machine | ||

| Mesh | Test results | Mesh | Test results | ||

| φ1000 | Silicon carbide | 500 | Unable to screening | 500 | 1500KG/H |

| Tungsten powder of cemented carbide | 600 | No fine powder was sifted out for 15 minutes | 600 | 30KG/H | |

| vitamin c powder | 400 | 1KG/H | 400 | 120-150KG/H | |

| φ500 | Pollen | 400 | No fine powder was sifted out for 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder,Cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| φ450 | Ndfeb powder | 300 | 32.2% residual sieve in 30 minutes | 300 | 6.9%residual sieve in 30 minutes |

For the screening of fine materials, dust pollution is an urgent problem for every enterprise. If the dust splash is prevented from the production process, can it effectively solve the dust pollution problem? ultrasonic sieving machines can achieve this. This is because the seal used is made of high-quality silica gel. The new design of the bundle ring can prevent the leakage of dust during the operation of the equipment. The top of the equipment is equipped with a dust cover to solve the problem of dust dissipation.

ultrasonic sieving machines are available in a wide range of models, from DHC-400 to DHC-2000. There are a variety of materials available for our customers, such as stainless steel, plastic, carbon steel, processing capacity up to 10t / h, but also according to user needs custom made

Ultrasonic sieving machine has a wide range of applications and obvious advantages. If you want to know more about it, you can contact customer service at any time.

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW |

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW |

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW |

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW |

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW |

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW |

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.