It solves the problem of sieving products with a high mesh number above 200 mesh or products with easy agglomeration and static electricity that are difficult to sieve by ordinary sieve shakers.

![]()

![]()

Price:$200.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

Diameter:100/200/300mm

Mesh Size:635 mesh

Feed amount: ≤500

Voltage: 110V-380V

Dimension(L*W*H):35*35*45

Weight: 25 KG

Application: High mesh over 200 mesh or fine powder that is easy to agglomerate and charged with static electricity. Such as pharmaceutical powder, robe powder, electromagnetic powder, metal powder, etc.

Commitment:

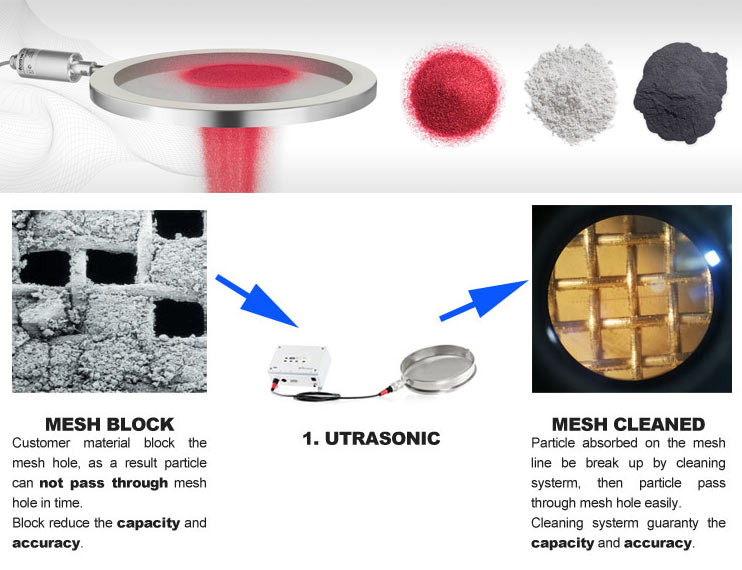

Ultrasonic sieve shaker is an ultrasonic transducer installed on the ordinary sieve shaker. It is a kind of inspection equipment for fine powder with high static electricity, strong adsorption force, high density and light specific gravity. It sieves as fine as 20 microns, while It will not block the sieve, which solves the current screening problems such as agglomeration, static electricity, and strong adsorption blocking the mesh when the current experimental sieve is used for fine powder sampling.

Ultrasonic sieve shaker can set the equal sieving time of the same material according to the needs to ensure the consistency of sample analysis data, reduce the inspection error to an extremely low level, and make the product quality data accurate.

Ultrasonic sieve shaker is composed of ultrasonic vibration controller DH-300T test sieve (host) in sieve shaker. The high-frequency electrical oscillation generated by the ultrasonic vibration power supply is converted into a high-frequency sinusoidal oscillation wave by the oscillator, and the oscillator transmits the oscillation wave evenly to the screen surface. The materials on the screen are subjected to low-frequency three-dimensional vibration, and ultrasonic vibration is superimposed, which can not only prevent the mesh from clogging, but also improve the screening output and quality. The added ultrasonic system can be added to any layer of the experimental sieve, and it is very convenient to install and disassemble.

With ultrasonic sieve support, the waves are evenly distributed and stimulate the test sieve at a continuously changing frequency. This has several efficiency-enhancing effects:

1. The high frequency vibration reduces the frictional resistance between the particles and the screen.

2. Decompose aggregated or agglomerated powder to prevent mesh clogging.

3. When the fine powder is damped or rubbed to generate static electricity, it will cause some materials in the troupe to agglomerate when damped or rubbed to generate static electricity. Under the action of ultrasonic waves, these agglomerates can be crushed for a second time, thereby increasing the output.

Prevent fine powder from clogging the screen

The ultrasonic frequency is applied to the sieve to truly solve the characteristics of strong adsorption, adhesion, viscosity, high static electricity, high density, ultra-fine powder and other materials, and the sieve is as fine as 635 mesh.

Cut costs

By eliminating screen clogging, the need to repair and replace damaged screens is reduced, thereby reducing production costs and additionally eliminating cleaning downtime.

0-99 minutes timing detection

The inspection and screening time is controlled by a time relay, which can realize free timing from 0 to 99 minutes.

Multi-layer screening

1-8 layers of screen frames can be installed, which can continuously divide a product into 8 different particle segments.

Since the transducer on the ultrasonic system of the ultrasonic sieve shaker directly acts on the grid to control the screen, the sieving effect will be better than that of the ordinary sieve shaker, especially the advantages in fine powder screening and detection will be particularly prominent , the table below lists the differences between these two sieve shakers:

| Comparison item | Ultrasonic Sieve Shaker | Ordinary Sieve Shaker |

| application | Allows separation down to 20 microns (#635 mesh) | 200 mesh or more coarse mesh, more than 200 mesh is easy to block the screen |

| screening effect | The vibration frequency is 36,000 times/second, which can quickly decompose the attachment, and the passing rate of the screen surface can be increased by 50%-400%, and the screen will not be blocked | During the process of sieving fine powder, it is easy to block the mesh, resulting in accumulation, thereby reducing the output and product quality |

| Cost of production | Screen clogging is eliminated, product quality is consistent throughout production, and there is no downtime to clean screens, reducing the risk of downtime | The screen surface needs to be cleaned after each use. If the screen is blocked during use, it needs to be shut down for investigation, which is costly. |

Bismuth tungstate ultrasonic sieve shaker

Alloy powder ultrasonic sieve shaker

| No. | Name | Unit | Date | Online consultation | |

| 1 | Test sieve frame | layers | 1-7 | ||

| 2 | Screen frame diameter | mm | φ200、φ300 | ||

| 3 | Sieve particle size | mm | 0.025-3 | ||

| 4 | Noise | db | <50 | ||

| 5 | Feeding amount (one-time) | g | <500 | ||

| 6 | Amplitude | mm | <5 | ||

| 7 | Motor | Voltage | V | 220 | |

| Rotating speed | R/min | 1450 | |||

| Power | KW | 0.18 | |||

| 8 | Dimensions | mm | 350: 350:300+N*50 | ||

| 9 | Machine quality | KG | 360 | ||

1. Standard test sieve (host) DH-300T test sieve is a particle size analyzer that can be automatically shut down at regular intervals to ensure test repeatability, and has comprehensive functions and simple operation. A granular material can be precisely separated into 2~8 particle segments at the same time. It can be used for the analysis of the fineness and foreign matter content of the slurry material.

2. The ultrasonic vibration power supply has a built-in microcomputer chip, which can automatically track the digital frequency of the whole process according to the different states of the ultrasonic wave.

3. The test screen frame is equipped with an ultrasonic oscillator on the national standard Φ 200 screen frame.

4. The time relay is a control electrical appliance that uses the electromagnetic principle or the mechanical principle to realize the delay control.

5. Cable connection is used between the high-frequency connecting line test screen frame and the ultrasonic vibration power supply.

6. Connector aviation connection plug-in. Oscillator High-performance ultrasonic conversion device.

Power supply instructions for the ultrasonic test sieve: The ultrasonic control system and the test sieve are powered separately, and both the test sieve and the ultrasonic power supply are single-phase.

The connection between the ultrasonic inspection sieve host and the ultrasonic vibration power supply: the plug on the connecting line of the oscillator in the test sieve frame is inserted into the socket behind the ultrasonic vibration power supply, turn on the power and the ultrasonic vibration power supply starts to work, and adjust the power knob according to the screening needs.

Operation method: first place the test sieve frame on the test sieve tray to adjust the height of the fixture, tighten the M12 and M8 nuts, then insert the power cord plug into the 220V socket, adjust the time timer according to the test requirements, turn on the switch test sieve to start working, the time timer The main unit is automatically turned off when it is reset to zero.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.