Ultrasonic Sieving Machine

Ultrasonic Sieving Machine Carbon Steel Ultrasonic Sieving Machine

Carbon Steel Ultrasonic Sieving Machine Small Ultrasonic Sieving Machine

Small Ultrasonic Sieving Machine Ultrasonic sieving machine with special feeding port

Ultrasonic sieving machine with special feeding port Ultrasonic sieving machine with silo

Ultrasonic sieving machine with silo

Screen powders on meshes as fine as 20 microns without blinding or blocking

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Diameter: DHC400-1800mm Mesh size: 60-635 mesh

Processing capacity: 0.2-5t/h

Ultrasonic vibration frequency: 38KHz

Transducer: Internal/External

Ultrasonic gear: continuous 1-9 gears, pulse 2 gears

Application: all kinds of high-precision powder, battery cathode and anode materials, pharmaceutical powder, carbon powder, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, electromagnetic powder, silicon powder, Coffee powder, alumina, etc.

Commitment:

DHC-800 ultrasonic sieving machine for sieving 80 mesh ceramic powder, about 14 catties in two minutes, without blinding or blocking

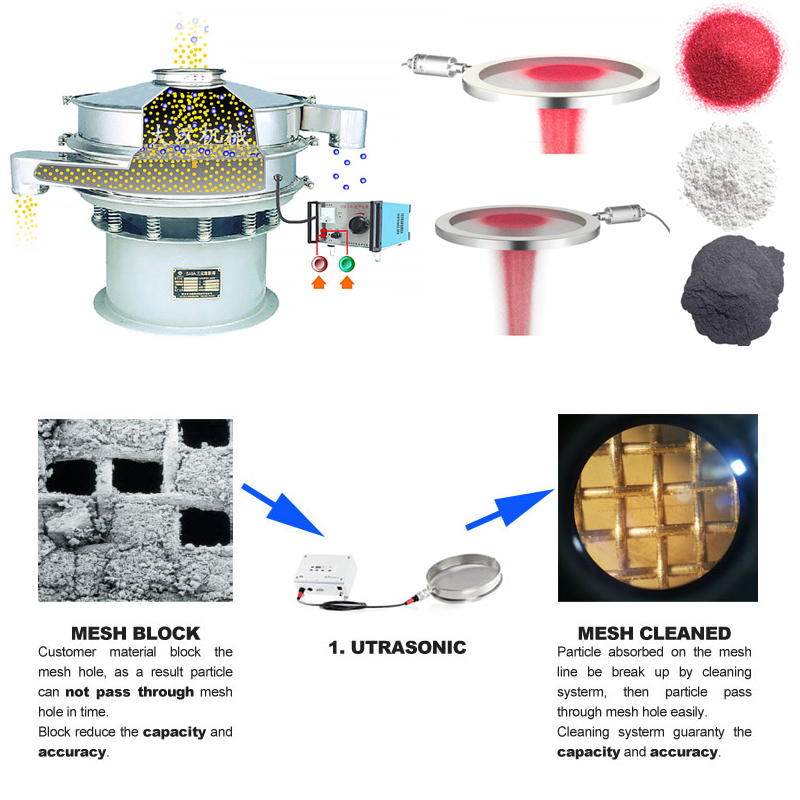

Ultrasonic sieving machine uses ultrasonic frequency to vibrate the screen, the vibration frequency can reach 36,000 times per second, which can make the fine powder material form a micro-suspended state on the screen, and can pass through the screen faster without generating static electricity and sticking to the screen. , and easier to screen powders, the system increases screening capacity by 10 times, increasing productivity while allowing separation accuracy down to 20m (#635 mesh), our ultrasonic system can be installed to new and existing vibrating screens and sieving machine.

Ultrasonic sieving machine is suitable for 400 mesh, 500 mesh and 600 mesh fine materials, such as graphite powder, diamond, glass powder, silica alumina powder, slurry, white latex, alumina, quartz sand, lithium battery cathode material, metal powder, fluorescent Powder, titanium powder, trace mineral powder, sulfur powder, high nickel ternary cathode material, epoxy powder, traditional Chinese medicine powder, catalyst, lithium battery powder, stainless steel metal powder, chili powder, diamond, matcha powder, etc.

1. Ultrafine powder screening: It really solves the screening problems of materials with strong adsorption, adhesion, viscosity, high static electricity, high density, ultrafine powder and other characteristics.

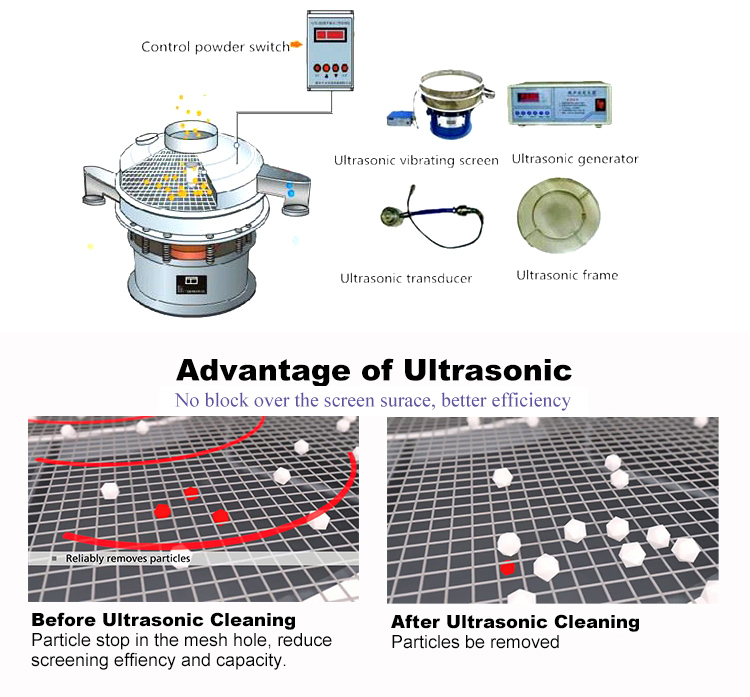

2. Solve the clogging of the screen: The ultrasonic system applies high-frequency, extremely low-amplitude vibration to the screen, and the vibration frequency is 36,000 times/min, which helps to deblind and fluidize fine products, making it easier to screen.

3. Cost reduction: Due to the elimination of screen clogging, the product quality remains consistent throughout the production process, and there is no need to stop the machine to clean the screen, reducing the risk of downtime and reducing production costs.

4. Increase the output: Since the screen will not be blocked, the screen can be cleaned without stopping, and the output can be increased by 0.5-10 times.

| Material Name | Material Properties |

| Silicon carbide | High hardness, small expansion coefficient, brittleness, good thermal conductivity, etc. |

| Wood powder | Light specific gravity, fluffy material, easy to agglomerate |

| Lithium battery material | It has good electrical conductivity and anti-classic performance, light weight, poor material fluidity, high viscosity and low output |

| Pharmaceutical powder | Light specific gravity, easy to agglomerate, easy to adhere |

| Epoxy powder | Thermoset powder coatings with corrosion resistance and toughness |

| Nickel ternary cathode material | High capacity, low cost, poor material fluidity, high viscosity, low output |

| Sulfur powder | Flammable, sterilizing, laxative. The fineness is 200 mesh, 325 mesh, 400 mesh and 500 mesh etc. |

| Graphite powder | Adsorption, easy caking, strong viscosity, high static electricity, etc. |

| Coating | Sticky and light, it will aggregate into particles and sometimes turn into dust, wasting raw materials and polluting the environment |

Ultrasonic sieving machine converts 220V, 50Hz or 110V, 60Hz electric energy into high-frequency electric energy such as 18KHz, inputting the ultrasonic transducer, and turning it into mechanical vibration such as 18KHz, so as to achieve the purpose of efficient screening and net cleaning. It eliminates the static electricity on the screen holes, the agglomeration of powder and the clogging problem caused by the particles inserted into the rough mesh surface, and does not change the characteristics of the screened material.

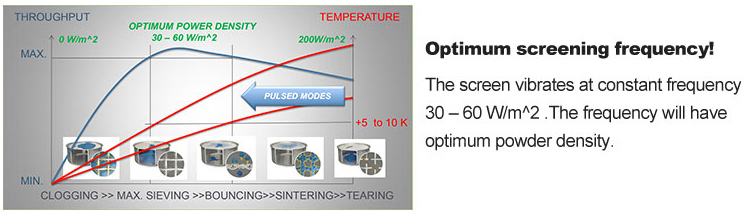

The frequency conversion device is to change the vibration frequency of the ordinary sieving machine, so that the vibration frequency of the material in the same unit time increases, thereby increasing the number of times the material passes through the sieve holes in the same time, making the sieving machine more efficient and finer, suitable for wider range.

Prevent blindness and blockage

Use ultrasonic frequencies to vibrate the mesh so that the mesh does not clog, while allowing separation accuracy down to 20 μm (#635 mesh).

Increase production

Ultrasonic sieving can make the powder pass through the sieve holes faster and increase the mesh penetration efficiency, thereby increasing the sieving capacity by 10 times.

Continuously working

The power supply can be adjusted automatically between 18K-40K, and the low frequency can be converted to high frequency according to the specific gravity of the material. The transducer can work continuously for 12-24 hours.

Upgrade existing systems

Can be installed onto new or existing shakers for easy integration into your production line.

Avoid production downtime

Preventing screen overloading not only reduces production downtime, but also reduces the time required to clean the screen.

Reduce operating costs

There is no need to clean the net with a rubber ball to prevent re-contamination caused by rubber abrasion.

| Model (mm) |

Test material | Ordinary Sieving Machine | Ultrasonic Sieving Machine | ||

| Mesh | Test Results | Mesh | Test Results | ||

| φ1000 | Silicon carbide | 500 | cannot be sieved | 500 | 1000KG/H |

| Tungsten carbide powder | 600 | 15 minutes without sifting out fine powder | 600 | 30KG/H | |

| Vitamin C Powder | 100 | 1KG/H | 100 | 120-150KG/H | |

| φ600 | pollen | 400 | 15 minutes without sifting out fine powder | 400 | About 20% fine powder is sieved in 15 minutes, and finer grading is possible |

| φ1000 | Nickel, Zinc, Cobalt Powder | 325 | 10KG/H | 400 | 300KG/H |

| Emery powder | 400 | Cannot be sieved | 300 | 13000KG/H | |

| material |  |

|

| SUS304 stainless steel: it is mainly used in medicine, food and other industries. The characteristics of SUS304 high-quality stainless steel are high temperature resistance and high toughness. | Q235A carbon steel: mainly used in the chemical industry, Q235A carbon surface steel features: good toughness and plasticity. | |

| grid |  |

|

| Adhesive mesh frame: high cleanliness, the whole mesh frame has no dead angle, the screen is directly bonded to the mesh frame, and the screen wire head and corners are not retained; suitable for the food and pharmaceutical industries. | Sub-mother grid: suitable for materials with large specific gravity and strong elaboration, the screen is easy to replace and difficult, and the cost of screen replacement is low; suitable for chemical and metallurgical industries, etc. | |

| clear net |  |

|

| The use of the mesh frame blocking ball and the pinball is a common net cleaning device, which is generally used for 100-200 mesh screens. | Ultrasonic cleaning device: - - Generally used for 400-500 mesh screen, features: high efficiency, good cleaning effect. | |

| Seals |  |

|

| Rubber seals: mainly used in the chemical industry, high and low temperature resistance, good odor resistance and electrical insulation. | Silicone seals: mainly used in the food and pharmaceutical industries, with high adsorption performance and good thermal stability. |

| Model | Diameter (mm) |

Screening area (m2) |

Screen size target |

Layers | Input power (V/HZ) |

Ultrasound model |

Transducer location |

Frequency (KHz) |

Ultrasound gear |

Power (Kw) |

| DHC-200 | ⌀200 | 0.03 | 10-1200 | 1-5 | 220/50 | DHC-7 | External | 38KHz | Continuous 1-9 gears Pulse 2 gear |

0.18 |

| DHC-400 | ⌀340 | 0.09 | 1-3 | Sieving machine 380/50 Ultrasonic sieving machine220/50 |

Built-in/External | 0.25 | ||||

| DHC-600 | ⌀540 | 0.23 | 0.55 | |||||||

| DHC-800 | ⌀730 | 0.42 | 0.75 | |||||||

| DHC-1000 | ⌀900 | 0.64 | 60-635 | 1.1 | ||||||

| DHC-1200 | ⌀1100 | 0.95 | 1.5 | |||||||

| DHC-1500 | ⌀1400 | 1.54 | 2.2 | |||||||

| DHC-1800 | ⌀1700 | 2.27 | 3 |

Special Instructions

This series of ultrasonic sieving machine has a variety of models to choose from, with high sieving rate, effectively preventing material from blocking holes, and effectively solving the problems of low sieving rate and small output of ultrafine powder. Various models can be customized for customers: gate type, moving wheel type, heightened type, airtight type, etc.

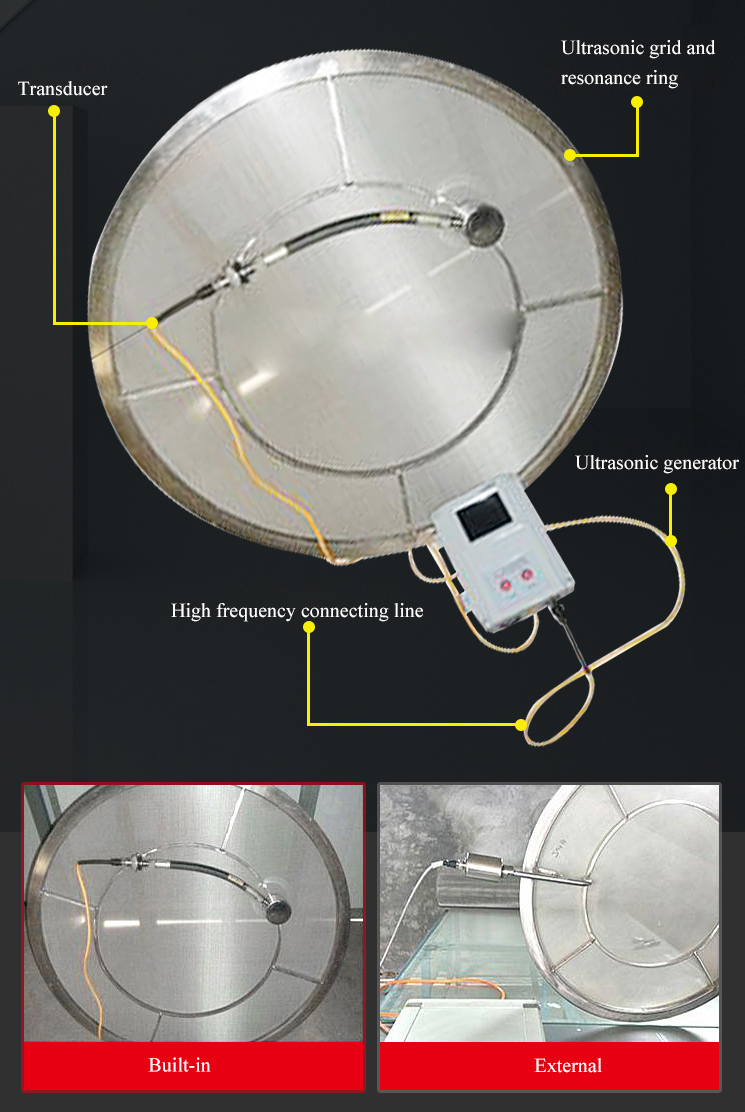

Ultrasonic sieving machine is mainly composed of ultrasonic resonance power supply, oscillator, outer mesh ring and resonance ring, screen mesh, mesh frame, vibration motor, damping spring and other parts.

Ultrasonic resonant power supply: high-frequency high-power ultrasonic resonant power supply generator, using digital frequency modulation and amplitude modulation, can automatically track the resonance point according to different states of screening (different material grid structure) to maximize power output, long-term work stability, and heat generation Small and easy to use.

High-frequency connecting line: A cable is used to connect the ultrasonic generator and the ultrasonic transducer.

Transducer: High-performance ultrasonic conversion device, sealed structure can prevent the entry of fine powder.

Ultrasonic grid frame: It consists of an outer grid frame and a resonance ring. According to the size of the frame, we can insert a variable number of waveguide rings into the frame to ensure the best ultrasonic performance.

Box Dimension (WxHxD): 165 x 230 x 400mm

Ultrasonic sieving machine can use different types of ultrasonic systems and ultrasonic grids according to customer requirements.

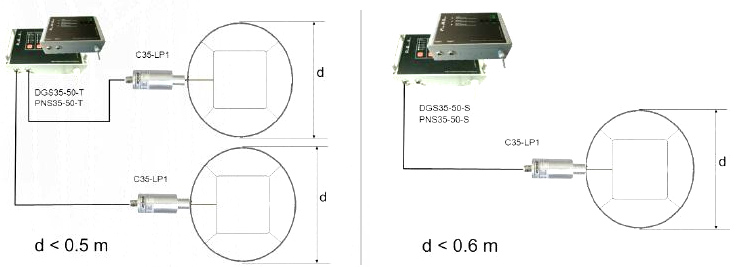

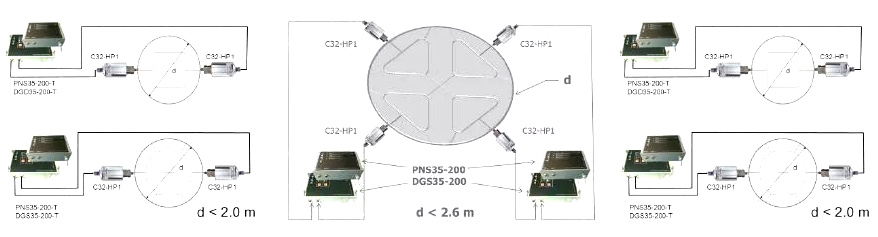

1. Optional built-in transducer and external transducer

2.It can be connected with a single ultrasound, or a single double ultrasound can be connected

3.Multiple series connection methods, more comprehensive coverage and more thorough screening

Ultrasonic sieving machine provides an effective screening solution for the unblinding of fine screens used in food, pharmaceutical and chemical industries.

Sieving metal powder

Removing impurities from metal powders, removing large particles or excess contaminants in metal powders, our ultrasonic systems are able to accurately screen powders on screens as fine as 20 microns without clogging.

Sieving powder coatings

To remove the ultrafine powder in the finished material, 300 mesh and 325 mesh national standard sieves are generally used for screening, and ultrasonic screening is usually used, which can effectively solve the problem of melting and agglomeration in coating screening.

Sieving food powder

To remove large particles or foreign contaminants in food powder, in order to improve the quality of the finished product, use the ultrasonic frequency vibration screen to prevent the screen from clogging.

Sieving 3D printing powder

Used to pre-screen powders before loading into 3D printers, our screening systems are equipped with ultrasonic screening systems and gas guards, which eliminate screen build-up and allow for seamless processing of powdered polymers with improved purity.

Dahan ultrasonic system provides an effective screening solution for deblinding of fine sieves used in the food, pharmaceutical and chemical industries, our factory can also provide a variety of different options according to each user's requirements, stock supply, guaranteed The supply is timely, and the manufacturer has passed the ISO9001 quality management system certification and the EU CE certification, with a one-year warranty and lifetime maintenance. Please contact us directly to learn more about ultrasonic system specifications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.