In the field of fine screening, the use of vibro sifters and ultrasonic sieving machines is the most extensive, but as two different products, there are many differences between vibro sifters and ultrasonic sieving machines. The next small series will give you a detailed introduction.

Ordinary vibro sifter can be used in the separation process of solids in liquids, for the separation of different particle sizes of the same product, for safe screening to eliminate foreign particles, for the homogenization of particles, etc., sieving up to 500 mesh, in fine sieving When the powder is used, the screen is prone to blockage.

The ultrasonic system of the ultrasonic sieving machine applies high frequency vibration to the screen. The frequency of vibration breaks surface tension, making the stainless steel mesh effectively frictionless and preventing oversized and undersized particles from clogging or clogging the mesh screen, sifting powders on screens as fine as 20 microns without clogging or clogging. The ultrasonic vibrating sieve makes it easier to separate ultrafine powders such as metal powders, paints, chemicals or food powders.

| Model (mm) |

Testing materials | Ordinary Vibro Sifter | UItrasonic Vibro Sifter | ||

| Mesh | Test results | Mesh | Test results | ||

| φ1000 | Silicon carbide | 500 | Unable to screening | 500 | 1500KG/H |

| Tungsten powder of cemented carbide | 600 | No fine powder was sifted out for 15 minutes | 600 | 30KG/H | |

| vitamin c powder | 400 | 1KG/H | 400 | 120-150KG/H | |

| Φ600 | Pollen | 400 | No fine powder was sifted out for 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder,Cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| Φ400 | Ndfeb powder | 300 | 32.2% residual sieve in 30 minutes | 300 | 6.9%residual sieve in 30 minutes |

As a superfine fine powder screening equipment, the vibro sifter can screen a fine particle of 500 mesh or 0.028 mm and filter 500 mesh slurry.

ultrasonic sieving machine is based on the vibro sifter and equipped with ultrasonic device. Therefore, it is more suitable for powder with finer particle size, higher viscosity, easy to agglomerate, high static electricity, high precision, high density and light specific gravity. Shaped material, larger than 500 mesh sieve.

Fine powders can be challenging in the sifting process, with ordinary vibro sifter it is easy to stick to the mesh, causing build-up, which reduces yield and product quality, ultrasonic deblinding system provides a fully automatic solution for mesh blindness , to increase productivity while preventing mesh damage, the data shows that the ultrasonic vibrating sieve will increase the processing capacity by 10 times than the ordinary vibro sifter.

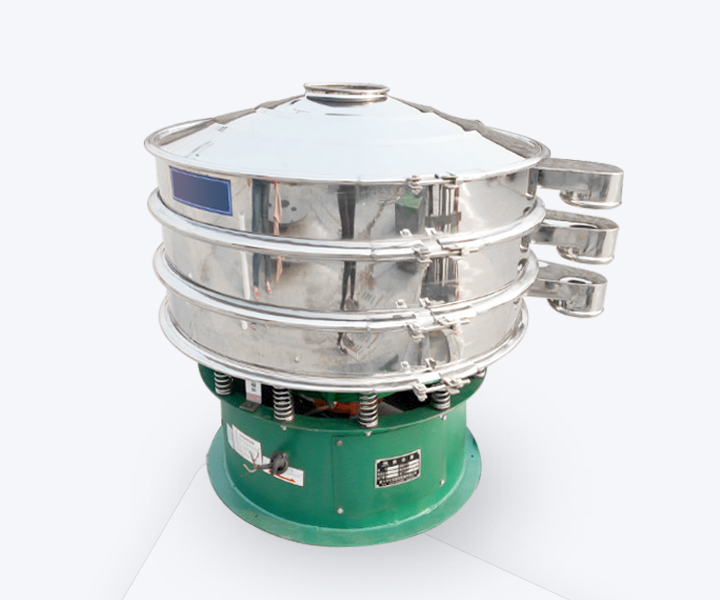

The vibro sifter is mainly composed of a feeding port, a dust cover, a discharge port, a bundle ring, a screen mesh, a weight block, an upper weight hammer, a vibrating body, a vibration motor, a spring, a lower weight, and a base.

The ultrasonic sieving machine is mainly composed of a dust cover, a transducer, a vibrating body, a vibration reducing spring, an ultrasonic power source, a base and the like.

The vibro sifter is an excitation source by an upright motor. When the screen is started, the eccentric weights installed on the upper and lower ends of the motor convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion. This movement is transmitted to the screen surface. In this process, the material smaller than the pore size of the sieve surface falls through the sieve hole to the lower layer, and becomes the undersize material. The material larger than the pore diameter of the sieve surface is discharged from the discharge opening after continuous jumping movement, and the weights of the upper and lower ends are adjusted by adjusting the upper and lower ends. The phase angle can change the trajectory of the material on the screen surface to achieve the purpose of screening.

The high-frequency electricity generated by the ultrasonic sieving machine power source is converted into a high-frequency sinusoidal longitudinal oscillation wave by an ultrasonic transducer, and the oscillation wave is transmitted to the resonator to resonate the resonator, and then the vibration is uniformly transmitted to the sieve by the resonator. On the surface, the material on the screen is superimposed with ultrasonic vibration while doing low-frequency three-dimensional vibration, which can prevent the mesh from being blocked and improve the screening output and precision.

The above is the difference between the vibro sifter and the ultrasonic sieving machine. Dahan Machinery reminds you to choose according to the characteristics of the material you are screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.