Utilizes powered continuous chain devices for moving product along assembly lines and/or manufacturing or warehousing facilities.

![]()

![]()

Price:$900.00 - $6,000.00/Set

Consult now and enjoy a 10% discount

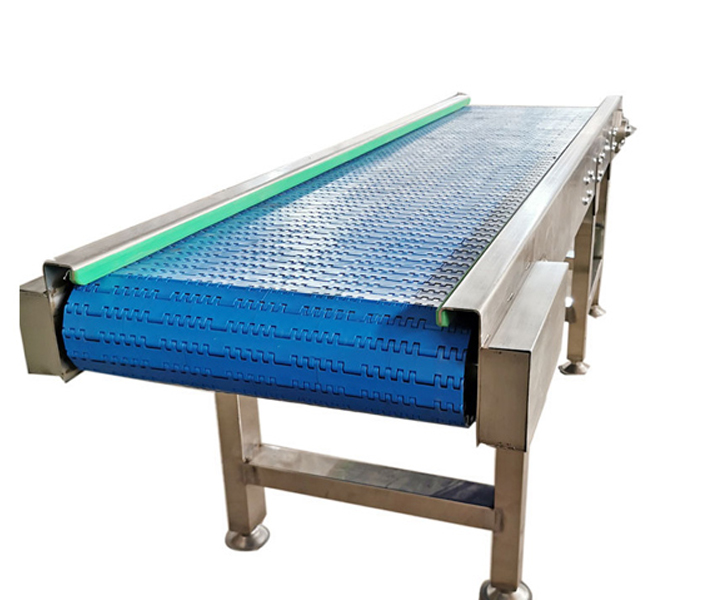

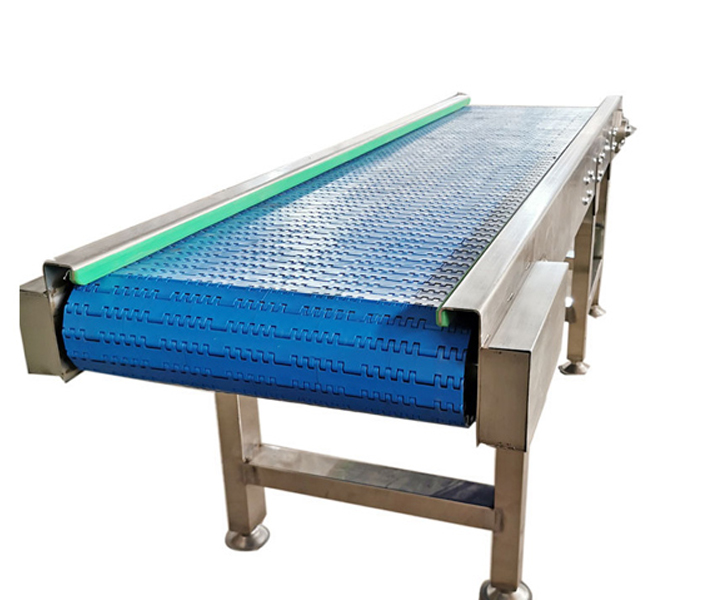

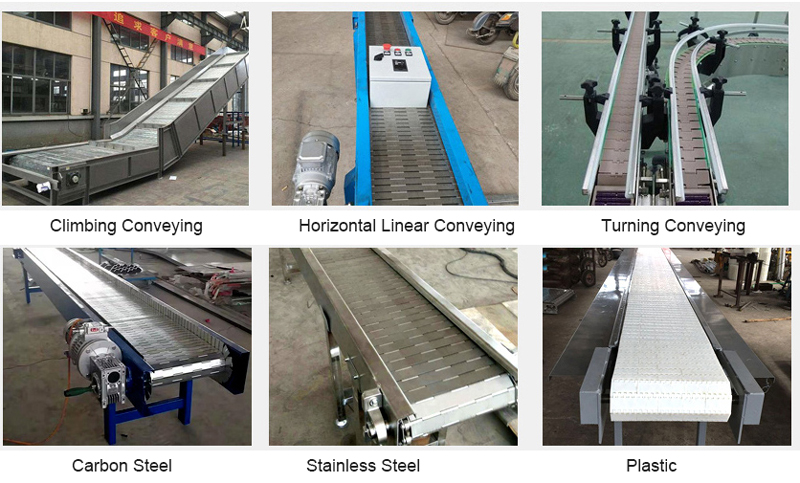

Chain plate width: 1200-2600mm

Chain plate material: carbon steel, stainless steel, plastic

Chain pitch: 38.1mm-200mm

Delivery capacity: 15-60 cubic / hour

Conveying distance: 70 meters

Conveying speed: 7-14 m/min

Motor power: 3-55kw

Application: Used in food, canned beverage, cosmetic products and other industries, especially suitable for the transportation of large volume and heavy goods, automatic conveying, distribution and in-line conveying of subsequent packaging.

Commitment:

Chain conveyors use an endless chain both to transmit power and to propel material through a trough, either pushed directly by the chain or by attachments to the chain. The chain runs over sprockets at either end of the trough. Chain conveyors are used to move material up to 90 metres (300 ft), and typically under 30 metres (98 ft).

The materials and specifications of the chain plates are all customized. For example, 304 stainless steel is selected for transporting food or high and low temperature resistance, and carbon steel is suitable for transporting relatively heavy materials without chemical reactions; there is also bottle washing. If the machine needs to drain the water, the perforated connecting plate is chosen as the bearing surface.

Chain conveyors are a type of mechanical conveyor system that uses chains to move materials along a predetermined path. There are several types of chain conveyors commonly used in various industries. Here are some of the most common types:

1.Slat Chain Conveyor: It use flat slats or plates linked together by chains to convey materials. They are often used for transporting hot, oily, or abrasive materials.

2.Drag Chain Conveyor: The chain is used to drag or move materials along the conveyor path. It is suitable for handling heavy or bulky materials.

3.Wire Mesh Chain Conveyor: It use a chain with a mesh or grid pattern to convey materials. They are suitable for applications where air or light needs to pass through the conveyor belt.

The following table shows you the differences between the above three types of chain conveyors:

| Differences | Slat Chain Conveyor | Drag Chain Conveyor | Wire Mesh Chain Conveyor |

| Chain material | Steel plate chain | Steel or plastic drag chains | Metal mesh belt |

| Conveying materials | Heavy, regular-shaped materials | Heavy, irregularly shaped materials | Lightweight, irregularly shaped materials |

| Conveying environment | High temperature, high humidity, corrosive environment | Harsh environments, such as dust and oil | Environment with high requirements for cleanliness and hygiene |

| Application scenarios | Automobile manufacturing, metallurgy, mining and other industries | Material transportation, automated production lines | Food, medicine, electronics and other industries |

| Advantages and disadvantages | Strong load-bearing capacity, but poor flexibility | Highly adaptable, but easily worn | Hygienic and easy to clean, but limited carrying capacity |

Chain conveyors are used in a variety of industries and applications for the handling and transportation of materials. Here are some examples:

Manufacturing: Transporting parts between workstations, assembly lines, and storage areas. They can be customized to suit different types of materials, including raw materials, finished products and heavy machinery.

Food Processing: Transporting food at all stages of production and packaging. They are designed to meet strict hygiene and safety standards and can be made from materials suitable for food contact.

Logistics: Used in logistics and distribution centers to move products between different stages of the supply chain. They can be used for truck loading, shipping packages and containers, and sorting delivered products.

Construction: Used on construction sites to move heavy materials such as concrete, steel and bricks. They are often used to transport materials to hard-to-reach areas and can be customized to fit different types of construction equipment.

Mining: Used in the mining industry to transport bulk materials such as coal, ore and aggregates. They can be designed to operate in harsh environments and can handle heavy loads over long distances.

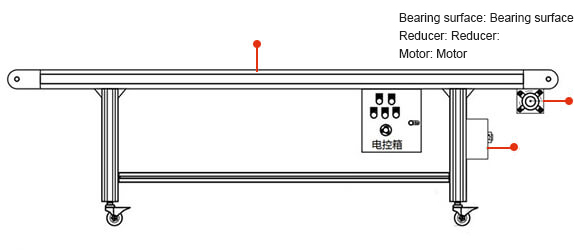

The working principle of a chain conveyor involves a chain that is driven by a motor and moves along a track or series of tracks. The chain is typically made of steel and is attached to a series of slats or plates that carry the material being transported. The slats or plates can be made of various materials depending on the application, such as plastic, wood, or metal.

When the motor is turned on, the chain begins to move along the track, pulling the slats or plates along with it. The material being transported is placed on top of the slats or plates and is carried along the conveyor as it moves.

Heavy handling

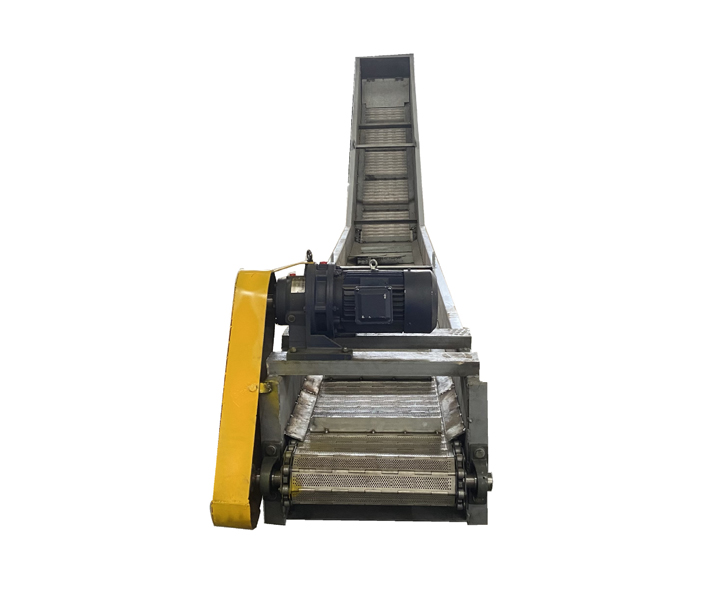

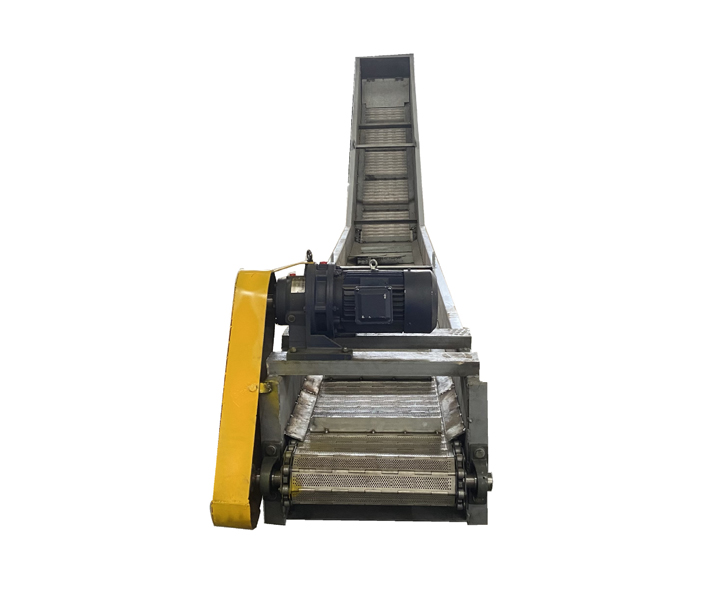

It is used to carry heavy objects and transport materials over long distances. The weight of a single material (piece) can reach 70-120kg, the conveying capacity can reach 60m/h, and the conveying distance can reach 90 meters.

Multifunction

Can be designed to suit various layouts and configurations, making it adaptable to different production environments

Low maintenance cost

Chain conveyors require relatively little maintenance compared to other types of conveyors. The chain is durable enough for long periods of continuous operation with minimal maintenance.

High-speed handling

Material can be moved at high speeds, ideal for time-critical applications. They are also able to process materials at different speeds, increasing production flexibility.

Improve security

They are equipped with safety guards that prevent workers from touching moving parts, reducing the risk of injury or accidents.

Reduce labor costs

Automation can be achieved, reducing the need for manual labor and increasing efficiency. This can save costs for companies that rely on manual labor for material handling.

The main differences between chain conveyors and belt conveyors are:

| Compared | Chain Conveyor | Belt Conveyors |

| Design | Consists of a series of chains attached to slats or plates to carry material along the conveyor. | Consists of a belt driven by a motor and moved along a track. |

| Load capacity | Designed to handle heavier loads than belt conveyors. Chain conveyors are often used in industrial settings to move heavy or bulky materials such as pallets, containers or products on an assembly line | Typically used in transportation and logistics to move lighter materials such as parcels and bulk products such as grain, fertilizers, cement, flour, etc. |

| Maintenance | Due to the higher number of moving parts, chain conveyors require more maintenance than belt conveyors | Fewer moving parts require less maintenance. |

| Cost | Typically more expensive than belt conveyors due to the greater amount of material required for their construction and higher load capacity. | Require less cost |

| Model | Product name | Chain pitch (mm) |

Ultimate strength of single chain (KN) |

Allowable chain tension (KN) |

Table width (mm) |

Load bearing (KGf/m) |

Speed (m/min) |

Operating temperature (℃) |

| BP40 | Light-duty flat chain conveyor | 8.1 | 31.1 | 8 | 200-300 | 50 | 1-12 | 0-150 |

| BP50 | 50.8 | 55.6 | 15 | 300 -400 | 100 | |||

| BP100 | Curved plate conveyor Single-lane plate conveyor Double-lane chain conveyor | 100 | 56 | 5 | 400-500 | 120 | ||

| BP150 | 150 | 136 | 30 | 600-800 | 200 | |||

| BP200 | 200 | 230 | 40 | 800-1200 | 500 | |||

| BP250 | 250 | 1000-1200 | 1200 | |||||

| BP300 | 300 | 1000-1500 | 1500 | |||||

| BP400 | 400 | 1200-1800 | 2000 | |||||

| DPB | Large flatchain conveyor (heavy duty) | 1500-3000 | 2000 | 1-20 |

The chain conveyor uses the standard top plate chain as the bearing surface, driven by the motor reducer, and runs on the special guide rail. According to the different process, the chain conveyor is divided into turning type and straight type.

Material: carbon steel, stainless steel, chain plates of different widths and shapes can be selected according to actual needs to complete straight lines, turning, lifting and other requirements.

The customized types of chain conveyors mainly include the following:

1. Heavy-duty chain conveyor: This type of conveyor is suitable for heavy-duty environments and can withstand large weights and pressures. For example, heavy-duty chain conveyors are often used in cleaning and drying equipment.

2. Large-angle chain conveyor: This conveyor has a large inclination angle and is suitable for scenes that require a large lifting height. For example, stainless steel chain conveyors are often used in the food processing industry to ensure food-grade hygiene standards.

3. Small chain conveyor: Suitable for occasions with limited space or requiring flexible layout. For example, small chain conveyors can be used in laboratories or small production lines.

4. Curved chain conveyor: Suitable for scenes that require curved conveying, and can adjust the conveying path according to needs. For example, curved conveyors are often used in loading and unloading scenes.

1. Food processing plant: In a food processing plant, chain conveyors are used to transport frozen meat to the packaging line. The conveying length is 30 meters and can handle 2,000 kilograms per hour, ensuring efficient circulation.

2. Automobile manufacturing plant: Automobile manufacturing plants use chain conveyors to transport body parts. The conveying length reaches 50 meters and can transport 1,000 pieces per hour, supporting precise assembly processes.

3. Electronic product production lines: On electronic product production lines, chain conveyors are responsible for conveying circuit boards. The length is 20 meters and can handle 3,000 pieces per hour, ensuring rapid testing and inspection.

4. Chemical plant: The chain conveyor in the chemical plant is used to transport granular fertilizers. The length is 25 meters and the conveying capacity is 1,500 kilograms per hour, which improves packaging efficiency.

5. Pharmaceutical factory: Pharmaceutical factories use chain conveyors to transport medicine bottles. The conveying length is 15 meters and can handle 2,500 bottles per hour, ensuring efficient operation of the production line.

WhatsApp:+86 15236742901

Address::China,Yanjin county forest park gate to the west 1000 meters north road.