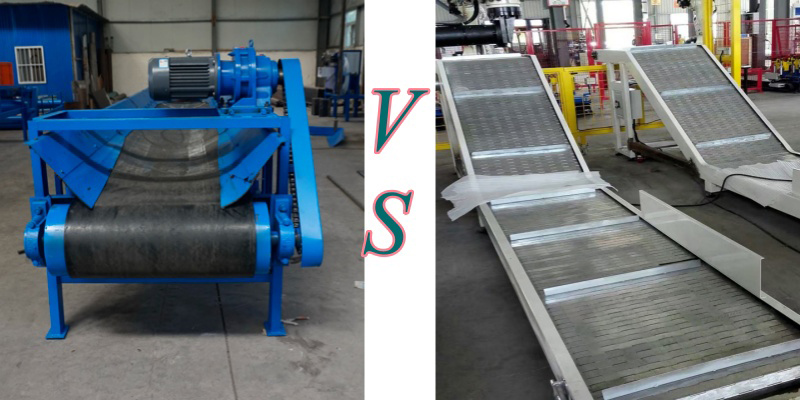

Different products have different uses, but a clearer understanding of the products can lead to better choices. Belt conveyors and Chain Conveyors have their own advantages and disadvantages. This article helps you choose the type of equipment that is more suitable for you through their differences.

Belt conveyor has a simple structure and is suitable for horizontal, inclined and vertical transportation; while the chain conveyor has a strong load capacity and is suitable for harsh environments and special working conditions. Choosing the right conveyor can improve production efficiency, and choose the right conveying equipment to meet needs based on material characteristics and working environment.

| Belt Conveyor | Chain Conveyor | |

| Scope of application | Belt conveyors are suitable for conveying bulk materials, granular materials, etc. | Chain conveyors are suitable for conveying heavy, high temperature, corrosive materials. |

| Performance features | It has stable operation and simple maintenance, and is suitable for long-distance transportation. | It has strong load capacity, wear resistance and corrosion resistance, and is suitable for harsh environments. |

| Structural features | Belt conveyor consists of conveyor belt, driving device, roller, tensioning device, etc. | Chain conveyors are composed of chains, sprockets, guide rails, rollers, etc. |

Belt conveyors

The belt conveyor carries the belt surface through idlers. These belt surfaces are usually very durable. If you have special needs, you can choose oil-resistant, high-temperature-resistant or food conveyor belts.

The advantages of belt conveyors mainly come from two aspects: soft belts and lower purchase costs.

The relatively soft belt conveying surface of the belt conveyor provides a gentle conveying surface for some fragile products, and the smooth and seamless belt surface is also easier to clean.

At the same time, the belt conveyor has a simple structure, and the price of the PVC material is competitive, so that compared with other conveyors, you can use the least cost and get the biggest profit.

Disadvantages of belt conveyors

Although special belts can be selected for belt conveyors, they still cannot achieve good results when conveying abrasive and heavy products, and they will be damaged quickly.

Chain Conveyor

Chain Conveyor usually connects short metal plates to form a flat conveyor belt, which is used to carry products and transport them to designated locations.

Advantages of Chain Conveyor

Metal conveyor panels are undoubtedly more durable, so the Chain Conveyor can accept larger loads.

Moreover, the conveyor belt of Chain Conveyor is formed by connecting short-distance metal plates, and the damage of a single section does not need to replace the entire conveyor belt. And if a part of the belt conveyor is damaged, it means that you need to replace the entire belt.

Disadvantages of Chain Conveyors

Because the conveyor belt of Chain Conveyor is spliced, there will inevitably be gaps. If it is not used to convey packaged food or packaged products, but to convey loose and unpackaged materials, the gaps of the conveyor belt will be filled soon, and the machine will become vulnerable.

In short, belt conveyors and chain conveyors are two common and widely used conveyors. They each have their own characteristics and application scenarios. Different conveyor types are used in different scenarios. If you are interested in the machine, you can refer to our product page to learn more, or you can consult online.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.