A coal mining company required a robust and high-capacity solution to transport large volumes of coal over long distances from the mine to a processing plant, under harsh environmental conditions. The Chain Conveyor for Transporting Coal proved ideal for this application, offering exceptional durability, continuous operation, and the ability to handle heavy loads and abrasive materials. Its enclosed design minimized dust emissions and ensured reliable performance in demanding settings, providing a cost-effective and efficient delivery system for the company’s needs.

The mining company installed a 5km long chain conveyor system to transport coal from the mine to the processing plant. The chain conveyor is designed for a maximum capacity of 2,000 tons of coal per hour.

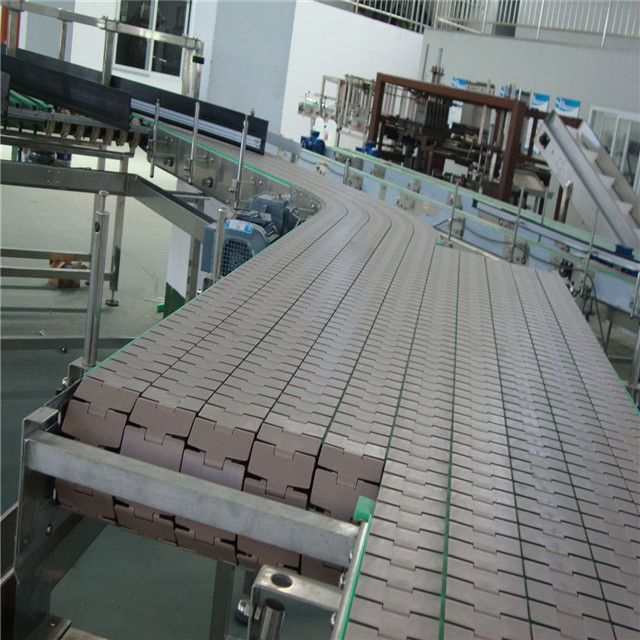

To ensure the conveyor can operate in the harsh mining environment, the chains and slats are made of high-strength steel. The conveyors are also equipped with a series of dust suppression systems to prevent the release of coal dust into the atmosphere.

Chain conveyors are powered by a series of motors located along the conveyor, which helps to distribute the load evenly and reduces the risk of downtime. The conveyor is also equipped with a series of sensors that monitor the temperature and vibration of the conveyor to detect any potential problems.

Chain conveyors are capable of transporting large quantities of coal over long distances with ease, reducing manual labor and increasing efficiency. The use of conveyor systems also ensures the safe and efficient transport of coal, reducing the risk of material damage or degradation.

Overall, the use of chain conveyor systems provides mining companies with an efficient and reliable method of material handling, reducing the risk of downtime and increasing productivity.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.