The chain conveyor uses an endless chain to transmit power and push the material through the groove, which is directly pushed by the chain or pushed by the accessories on the chain. The chain runs on the sprockets at both ends of the groove. Up to 90 m (300 ft), usually below 30 m (98 ft). This article will introduce the working principle of the chain conveyor in detail.

Once the product you need to transport is safely loaded onto the chain conveyor, the system is powered by operating an ON/OFF button or switch, which causes a clockwise or counterclockwise rotational motion of the motor system, depending on The desired direction of movement, so that the mesh gear and chain move in the same direction as the motor, as a result, the chain conveyor moves the load through the drive system to the last gear where unloading is done, and for one-way operation, the conveyor system It can also be customized to provide movement in either direction by installing two or more motors at each end of the conveyor system.

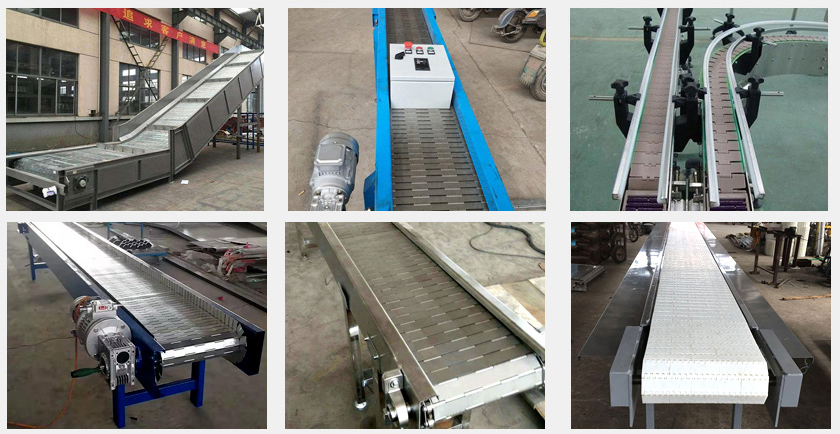

The chain conveyor is composed of motor, drive shaft, sprocket, chain, bearing, lubricant, chain plate, roller, tensioning equipment, etc. Among them, the chain and the chain plate mainly play the role of driving the movement of the product. The chain uses the cyclic reciprocating motion to provide traction power, and the metal plate is the carrier. Under the action of the traction force of the chain, the bearing material is transported along the horizontal or inclined direction.

The above is the introduction of the working principle of the chain conveyor. The chain conveyor can ensure the extraction and transportation of bulk materials over a long distance. The equipment can be transported horizontally, inclined and vertically. The industry has a wide range of applications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.