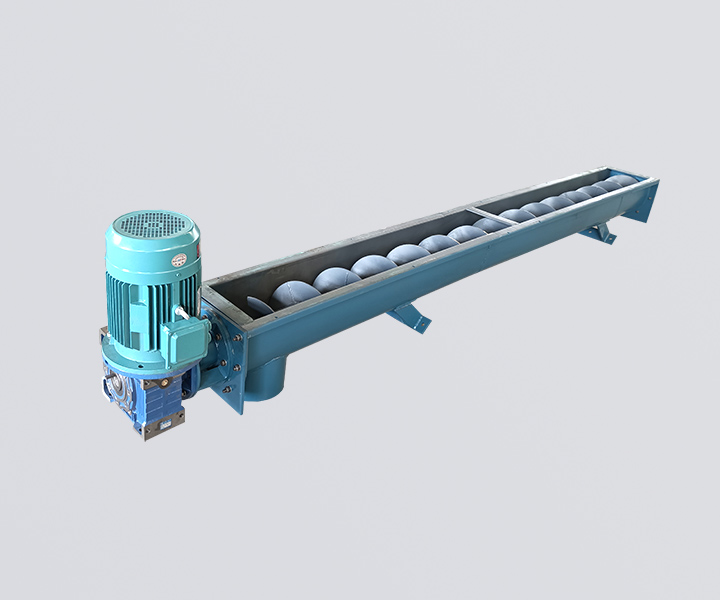

screw conveyor

screw conveyor shaftless screw conveyor

shaftless screw conveyor warm screw conveyor

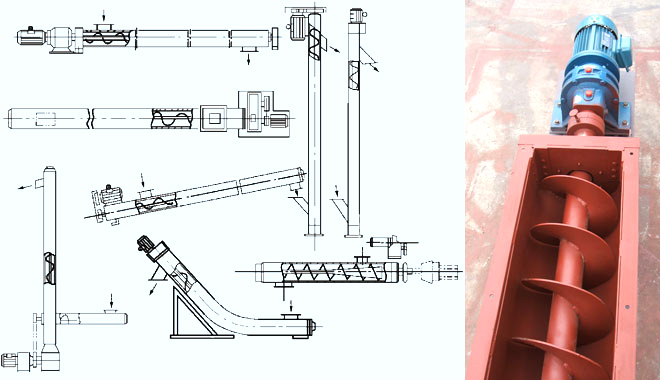

warm screw conveyor inclined screw conveyor

inclined screw conveyor vertical screw conveyor

vertical screw conveyor

For conveying bulk materials from almost any position (vertical, horizontal or inclined)

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100mm-1250mm

Capacity: 458m³/h

Length: 2-70 meters

Angle of Inclination: 0-90°

Customized: shaft/shaftless, tubular/U-shape, single shaft/double shaft

Application: Used to transport large quantities of granular solids (e.g., powders, granules, granules), semi-solids, liquids, and even non-flowing materials from one point to another, including concrete, dry sand, gypsum, fly ash, grain, etc.

Commitment:

Screw conveyor is a mechanical conveying system used to transport bulk materials from one location to another. It consists of a rotating screw inside a trough or tube, which moves the material along the length of the trough or tube. The screw is typically made of metal or plastic and has helical flights that act as paddles to move the material.Screw conveyors can be used to transport a wide variety of materials, including powders, granules, flakes, and pellets.

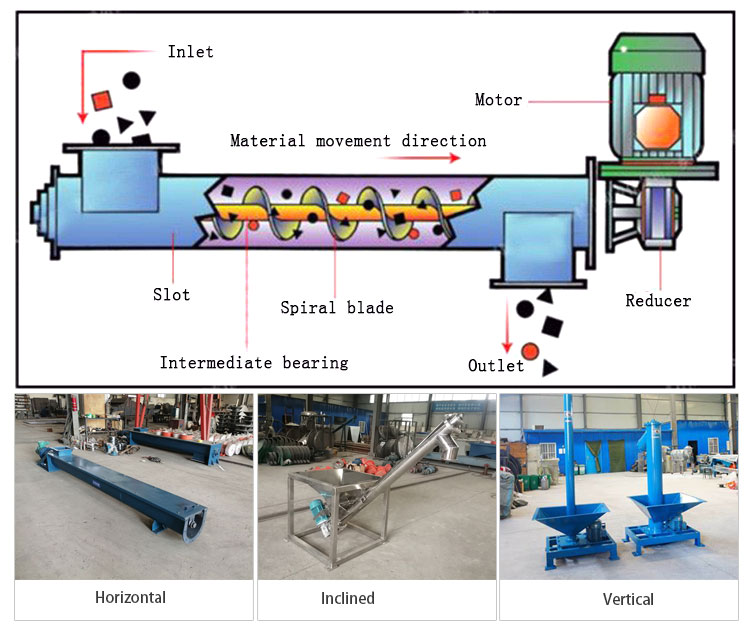

It is suitable for cement, food, chemical, agriculture and other industries and used for horizontal, inclined or vertical material transportation, and can realize large-volume and continuous material transportation. Screw conveyors can be divided into horizontal screw conveyors, inclined screw conveyors and vertical screw conveyors according to different needs. They are widely used in various industrial fields and provide efficient solutions for material transportation.

Tubular Screw Conveyor

It is mainly used for horizontal, inclined and vertical conveying of powdery or granular materials. The high speed can ensure smooth, fast and uniform conveying, and it is not easy to jam the material. The sealed pipeline design ensures no dust during the conveying process and the material is not easy to leak.

U-Type Screw Conveyor

It is suitable for horizontal/small inclination transportation, the inclination angle does not exceed 15°, and the sealing performance is good, which can avoid the generation of dust during the transportation process. The upper rainproof type cover is detachable, which is convenient for later maintenance and repair.

Shaftless Screw Conveyor

It is designed with no center shaft, which provides a non-clogging conveying surface and eliminates the accumulation of sticky materials, making it especially suitable for conveying pasty materials, semi-fluid and sticky materials, wet and strip materials, such as municipal solid waste, sludge , kitchen waste, household waste, etc.

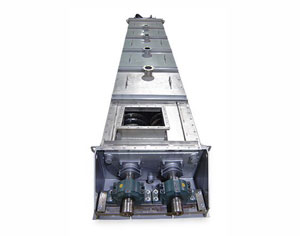

Double Screw Conveyor

It is composed of two screws and is mainly used when the material needs to be mixed when it moves to the destination. It is divided into two designs: double shaft and double shaftless. It is suitable for conveying poor fluidity, large volume or particle size, and needs to be stirred. materials.

Cooling Screw Cnveyor

It is a conveying equipment that integrates cooling and conveying. It is equipped with a water cooling system. The cooling water flows from the empty pipe at the inlet end through the cavity of the spiral plate and then flows out from the empty pipe at the initial stage to form a cooling water channel. It can achieve the specified outlet temperature of the product and is suitable for conveying High temperature fly ash, cinder, rubber powder, carbon black and other materials.

A screw conveyor works by using a rotating screw inside a trough or tube to move bulk materials from one location to another. Here's how it works:

Material is fed into the screw conveyor through a hopper or other inlet.The rotating screw inside the trough or tube moves the material along the length of the trough or tube. The helical flights on the screw act like paddles, moving the material forward with each rotation of the screw.As the material moves along the length of the trough or tube, it is compacted and compressed by the screw. This helps to prevent the material from becoming aerated or separated during transport.At the discharge end of the screw conveyor, the material is released from the trough or tube. This can be done by using a slide gate, valve, or other mechanism.

Wide range of applications

The scope of application of screw conveyor products is very wide, and can be used in many fields such as storage, food, chemical industry, waste water, etc., and it is used in some industries to mix various materials and break lumps.

Easy to arrange

There are multiple entry and discharge points. It can discharge materials at different points as needed. The flow of material can also be controlled with the aid of sliding gates or valves.

High conveying efficiency

The screw conveyor can quickly complete the transportation of materials and ensure the stability and accuracy of the material transportation process.

Safe and reliable

Internal pressure and steam can be maintained. This is very important when we are dealing with toxic or hazardous materials.

Small footprint

Compact size, small size, small footprint, easy access to hatches and compartments during unloading operations at ports.

Dust-free and pollution-free

It can realize sealed transportation, which is conducive to the transportation of easily flying, hot and strong-smelling materials, which can reduce the pollution to the environment and improve the working conditions of workers.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

You provide the following parameters before purchasing:

Our manufacturer selects and designs according to the parameters you provide. We have 15 years of experience in design and production, and the product quality is good.

1. If you are replacing, you need to provide the flange size (round or square), flange (outer diameter, inner diameter, flange hole distance), and the distance between the inlet and outlet. If it is a new installation, you can ignore these parameters. When you install Just do it to our size.

2. It is necessary to provide some parameters such as installation conditions, material name, material particle size, whether the material has hardness, whether the material has viscosity, material temperature, import and export distance, and the conveying capacity you need. We will help you choose a reasonable model to achieve You need to ensure that you can use it with comfort and peace of mind.

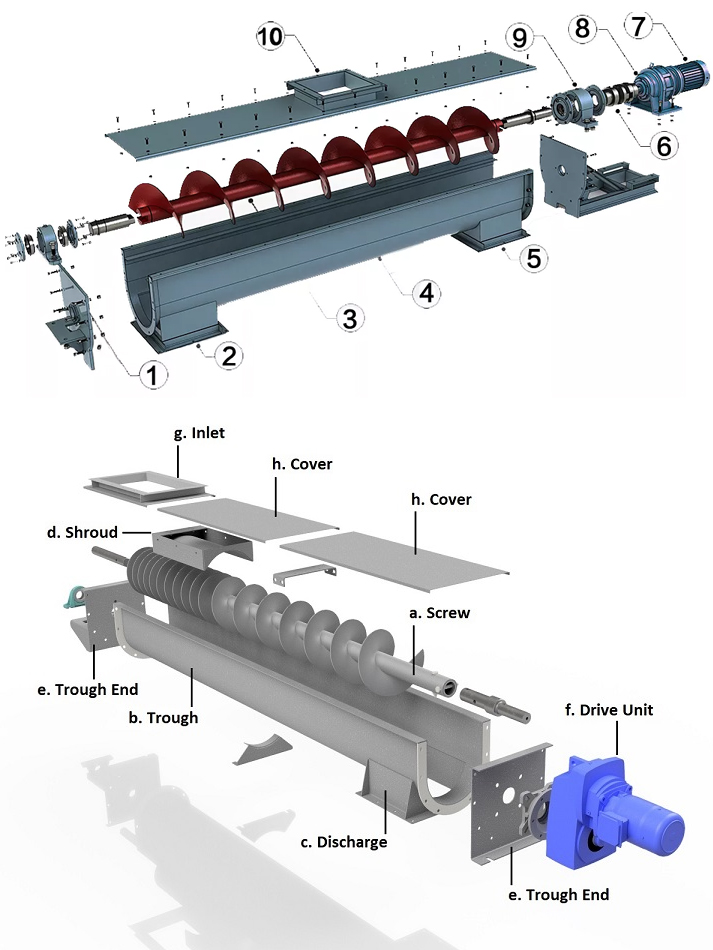

The basic structure of a screw conveyor consists of three main components: the screw, the trough or tube, and the drive system. Here's a breakdown of each component:

1. The screw: The screw is the main component of a screw conveyor and is typically made of metal or plastic. It consists of a helical flight that wraps around a central shaft. The size, shape, and pitch of the helical flight can be customized to fit the specific needs of a particular application.

2. The trough or tube: The trough or tube is the housing for the screw and provides a channel for the material being transported. It can be made of metal or plastic and can be designed to fit the specific needs of a particular application. The trough or tube can be straight or curved, and can be designed to operate at an incline or decline.

3. The drive system: The drive system is responsible for rotating the screw and moving the material along the length of the trough or tube. It typically consists of a motor, gearbox, and coupling. The speed and direction of the screw can be controlled by the drive system to fit the specific needs of a particular application.

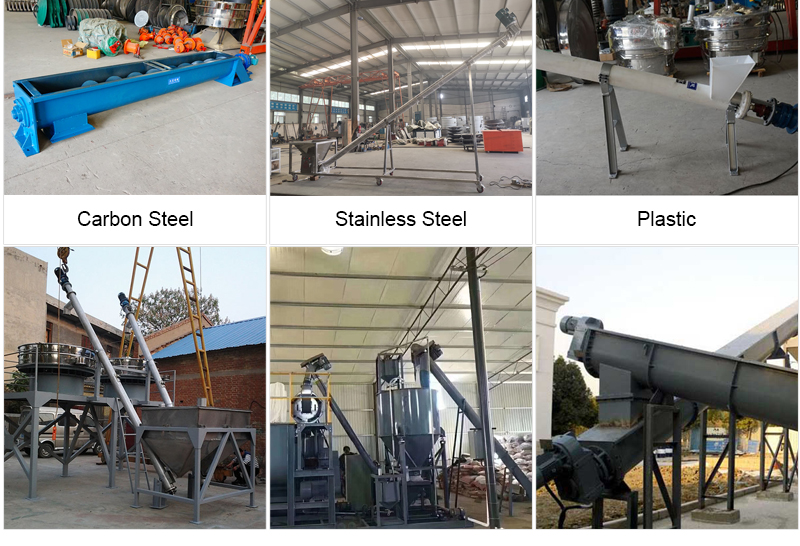

Screw conveyors can be customized to fit the specific needs of a particular application. Here are some of the options that are available for screw conveyors:

| Trough or tube material | Includes carbon steel, stainless steel, and plastic. The material of the tank or tube will depend on the specific application and the type of material being transported. |

| Screw material | Including carbon steel, stainless steel, plastic, etc. The material of the screw will depend on the specific application and the type of material being transported. |

| Flight design | Pitch, diameter and blade shape can be adjusted to optimize screw conveyor performance. |

| Drive system | A choice of motors, gearboxes and couplings are available to provide the required speed and torque to the screw conveyor. |

| Inlets and outlets | Can be designed to match the shape and size of the equipment that feeds or exits the screw conveyor. |

| Covers and inspection ports | A cover and an inspection port can be added for easy inspection and maintenance. Covers can be designed to be removable or hinged, and inspection ports can be located at strategic points along the length of the screw conveyor. |

Screw conveyors are commonly used in various industries for conveying bulk materials. Here are some of the most common applications for screw conveyors:

1. Agriculture: Machines are used in agriculture to transport grain, seeds and other bulk materials. They can be used to move material between different parts of a processing facility, or to load and unload trucks and railcars.

2. Food processing: used in food processing industry, conveying flour, sugar, spices and other ingredients, as well as finished products such as snacks and oatmeal. They are often used to move materials between different processing stages, such as mixing, baking and packaging.

3. Chemical industry: used in the chemical industry to transport powdery, granular and other materials. They can be used to move material between different stages of the manufacturing process, or to load and unload containers.

4. Mining industry: used to transport minerals, ores and other bulk materials in the mining industry. They can be used to move material between different parts of a processing facility, or to transport material to and from mine sites.

5. Garbage treatment: used for garbage treatment, transporting sludge, ash, garbage and other materials. They can be used to move materials between different stages of the waste management process, or to transport materials to and from landfills.

6. Power generation: used to transport coal and other fuel materials in power generation facilities. They can be used to move material between different parts of a facility, for example from a warehouse to a boiler.

Screw conveyors are used in material handling for a variety of reasons, including:

1. Efficient Transport: Used to efficiently move bulk materials from one point to another. They can be used to transport material horizontally, vertically or at an incline, making them a versatile choice for material handling.

2. Versatility: It can be used to convey various materials, including powder, granules, flakes and pellets. They are commonly used in industries such as agriculture, food processing, mining and chemical manufacturing.

3. Cost-effective: Usually less expensive than other types of material handling systems such as bucket elevators or pneumatic conveyors. They also require minimal maintenance, which further reduces operating costs.

4. Space saving: takes up less space than other types of material handling equipment, such as belt conveyors or bucket elevators. This is especially beneficial in facilities with limited space.

5. Ease of Installation: Easy to install and can be customized to a facility's specific needs. They can be designed to fit in tight spaces or transport materials over long distances.

The following table will introduce the differences between screw conveyors, belt conveyors and bucket elevators:

| Compare Items | Screw Conveyor | Belt Conveyor | Bucket Elevator |

| Features | Use a rotating screw inside a trough or tube to move material. They are usually used for horizontal or inclined transportation of materials | Use a rotating screw inside a trough or tube to move material. They are usually used for horizontal or inclined transportation of materials | Transport material vertically using a series of buckets attached to belts or chains. They are typically used for vertical transport of materials over short to medium distances, minimizing damage to the product. |

| Application | It is a good choice for horizontal or inclined conveying of viscous or easily caking materials. It is also a good choice for applications where space is limited. | It is a good choice for horizontal or inclined conveying of viscous or easily caking materials. It is also a good choice for applications where space is limited. | It is a good choice for vertical transportation of materials in short and medium distances. It's also a good choice for brittle or easily broken materials. |

| Cost | Usually less expensive than other types of conveyors and requires minimal maintenance. | Usually less expensive than other types of conveyors and requires minimal maintenance. | Typically more expensive than screw or belt conveyors, but can handle greater volumes of material and are less prone to damage or wear. |

Screw conveyors can be divided into horizontal type, inclined type and combined type according to the configuration form. It can complete centralized conveying, separately conveying, mixing materials, mixing, dewatering, customized batching, unloading and stacking, and use it with other conveying equipment.

We have a group of professional research, engineering, production, sales and after-sales service teams to serve customers all over the world. The company provides a full range of conveying equipment, which can be reasonably selected and designed according to the particle size, conveying volume, and conveying distance of the conveyed material, so as to ensure that the material is not jammed, arched, and discharged smoothly. Parameters and drawings are provided free of charge.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.