Is a material handling equipment used to move material from one location to another.

![]()

![]()

Price:$800.00-$6,000.00/Set

Consult now and enjoy a 10% discount

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying speed: 1.25-2m/s

Conveying length: 10 meters

Belt material: PVC/PU rubber

Frame Material: Carbon Steel/Stainless Steel

Angle: 0°-90°

Application: The material can be transported from the initial feeding point to the unloading point inclined or vertically, used in chemical, electronic, food processing and other industries

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Belt conveyor system is a material handling device used to move material from one location to another. They are commonly used in production, manufacturing and distribution facilities to transport goods and materials over short or long distances.

Belt conveyor systems are versatile and can be used to handle a wide variety of materials, including bulk materials, packaged goods, and heavy or irregularly shaped items. They are also relatively low maintenance and can be designed to be easily cleaned and sanitized, which is important for industries such as food and pharmaceuticals.

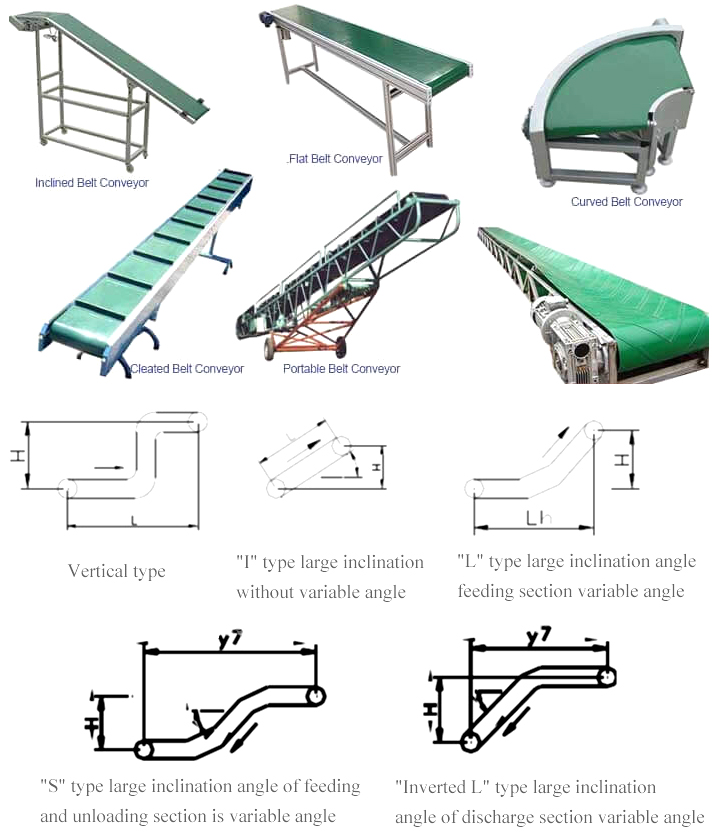

There are several different types of belt conveyor systems, each designed to meet specific material handling needs and requirements. Here are some of the most common types:

| Type | Horizontal Belt Conveyor | Inclined Belt Conveyor | Mobile Belt Conveyor | Z Type Belt Conveyor |

| Image |  |

|

|

|

| Features | Used to convey product horizontally from one location to another | For conveying material up a slope or higher. | Usually mounted on wheels or tracks, this can be moved quickly and easily to different locations as required. | The ability to move material vertically and horizontally makes it an ideal solution for applications with limited space. |

| Capacity | 28-800m³/h | 84-503m³/h | 28-800m³/h | 28-800m³/h |

| Length | 20 meters | 10 meters | 6 meters | 6 meters |

| Type | Hydraulic Lifting Belt Conveyor | Height Adjustable Belt Conveyor | Telescopic Belt Conveyor | Food Grade Belt Conveyor |

| Image |  |

|

|

|

| Features | With a hydraulic lifting mechanism, the conveyor belt can be raised and lowered, allowing materials to be loaded or unloaded at different heights. | The conveyor can be raised or lowered to different heights, allowing material to be loaded or unloaded at different heights. | It is designed with a telescoping mechanism that allows the conveyor to extend or retract in length. | It is designed and manufactured to meet the stringent hygiene and hygiene requirements of the food and beverage industry. |

| Capacity | 160 m³/h | 50-400t/h | 50-400t/h | 28-800m³/h |

| Length | 1.7-6 meters | 2.7-12 meters | 3-26 meters | 6 meters |

Working principle of belt conveyor systems is to use a driving device to drive the conveyor belt to move. Conveyor belt circulates along the roller to transport materials from the starting point to the end point. Material is placed on the conveyor belt and transported continuously. Driving device is an electric motor. Power is transmitted to the conveyor belt through the transmission device to push conveyor belt to move. Conveyor belt forms a closed cycle under the support of the roller. Entire system controls the start and stop, speed adjustment and direction change of conveyor belt through the control device.

Efficiency

Large quantities of material can be moved quickly and easily. This helps improve process efficiency and reduce labor costs.

Wide range of applications

They can also handle a wide variety of materials, including bulk materials, packaged goods, and heavy or irregularly shaped items.

Strong conveying capacity

There are many models and specifications, the conveying capacity is between 30 and 3000 tons per hour, and the conveying capacity can reach 203 meters. Different designs can also be adopted according to the actual situation on site.

Durability

Belt conveyor systems are durable and require minimal maintenance. They are designed to withstand heavy use and operate in harsh environments.

Customizable

Can be customized to meet the specific needs of the application, including conveyor length and width, type of belt, and conveyor speed and direction.

Improved safety

Belt conveyors are designed with safety features such as guards, emergency stops, and sensors to prevent accidents and injuries.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

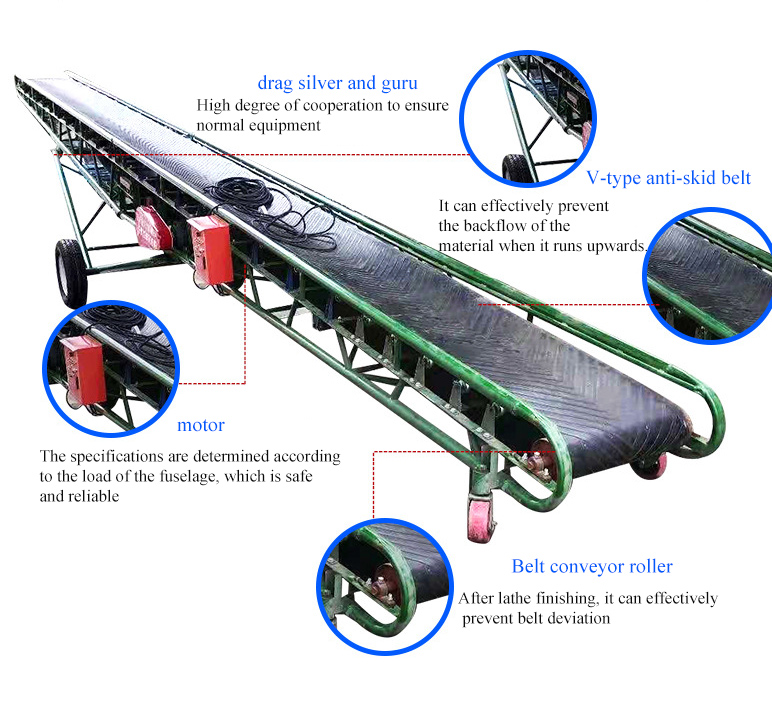

Belt conveyor systems are mainly composed of conveyor belts, idlers, rollers, elastic devices and other parts.

Conveyor belt: It has the characteristics of oil resistance, acid and alkali resistance, and the appropriate conveyor belt material can be selected according to the nature of the material.

Idler: ①Users can determine the horizontal position by adjusting the center idler to avoid the deviation of the material during the conveying process. ②The buffer idler is installed at the receiving place to reduce the impact of the material on the belt and reduce the belt tension. wear.

Roller device: The purpose of the reversing roller is to change the running direction of the tape and increase the wrapping angle of the drive roller, so that the tape forms a closed loop.

Tightening device: Make the conveyor belt reach the necessary tension, which can effectively reduce the possibility of slippage on the driving roller, and ensure that the deflection of the conveyor belt between the idlers is within a normal range.

When designing a belt conveyor, the major parameters to be considered are:

Motor and gearbox selection

To aid the selection of the motor, one must first know what the effective pulling force required for the conveyor is.

Speed of belt

The speed of the conveyor will be the circumference of the drive pulley multiplied by the revolutions per unit time.

Tension and take-up

A properly tensioned belt will wear evenly and will contain material evenly in the trough and run centrally when going over the idlers.

Take-up is an important component in maintaining and achieving optimum belt tension.

Material to be conveyed

The type, particle size, humidity, etc. of the material need to be considered to determine the material, structure and load-bearing capacity of the conveyor belt.

Transportation distance

Consider the horizontal distance and vertical height of the conveyor to determine the length, drive power and support structure of the conveyor belt.

Working environment

The working environment includes temperature, humidity, etc.

Belt conveyor systems are widely used in various industries for efficient material handling. Here are some common applications for belt conveyor systems:

Manufacturing: Used to transport raw materials, components and finished products between different stages of the production process. They can be used on assembly lines, packaging, sorting and distribution of goods.

Mining and Quarrying: For transporting bulk materials such as coal, ore, gravel, sand and aggregates. They are essential for efficient, continuous material movement over long distances, including overburden removal, stacking, and truck or railcar loading and unloading.

Food and Beverage: For handling and processing of food. They are used to transport raw materials, packaging materials and finished products such as bottles, cans, boxes and packaged food. Food-grade belt conveyors ensure compliance with hygiene and sanitation standards.

Warehousing and logistics: Critical to the movement of goods, including pallets, cases and containers, in warehouses and logistics centers. They facilitate efficient loading and unloading of trucks, cross-dock operations, and sorting and distribution of cargo within facilities.

Agriculture: For handling and transporting crops, grains, seeds, fertilizers and other agricultural products. They facilitate loading and unloading of materials from storage bins, trucks and railcars.

Construction: For moving construction materials such as sand, gravel, concrete and construction waste. They facilitate efficient material handling and can be used to transport materials to various work areas on site.

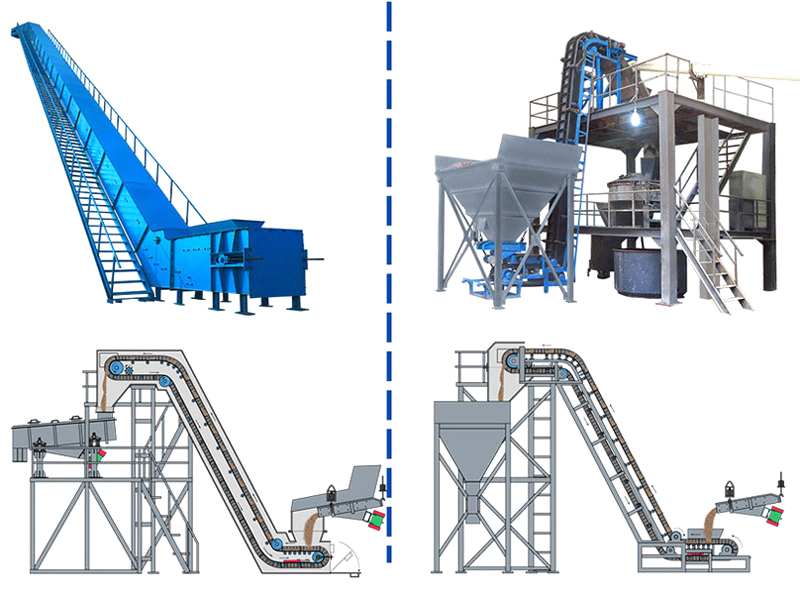

A mining company introduced a belt conveyor system produced by Dahan to improve the efficiency of ore transportation. The belt conveyor system includes multiple conveying lines, which can automatically adjust the transportation speed and direction to meet different process requirements. Through this system, ore can be transported from the mining point to the processing plant without manual intervention, which greatly reduces transportation costs and human resources. The system is stable and reliable, improves production efficiency, and saves costs for customers.

The main products of Dahan belt conveyor system manufacturers are: TD belt conveyor, inclined belt conveyor, mobile belt conveyor, telescopic belt conveyor, lifting belt conveyor, climbing belt conveyor, mining belt conveyor and other equipment. The products are in sufficient stock, and regular models can be shipped within 24 hours.

The company has established a complete pre-sale, sale, and after-sales service to achieve rapid response within 30 minutes, rush to the customer's site survey within 72 hours, and quickly on-site repair within 24 hours.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.