For handling and transporting coal during all stages of coal mining and processing operations

![]()

![]()

Price:$800.00-$8,000.00/Set

Consult now and enjoy a 10% discount

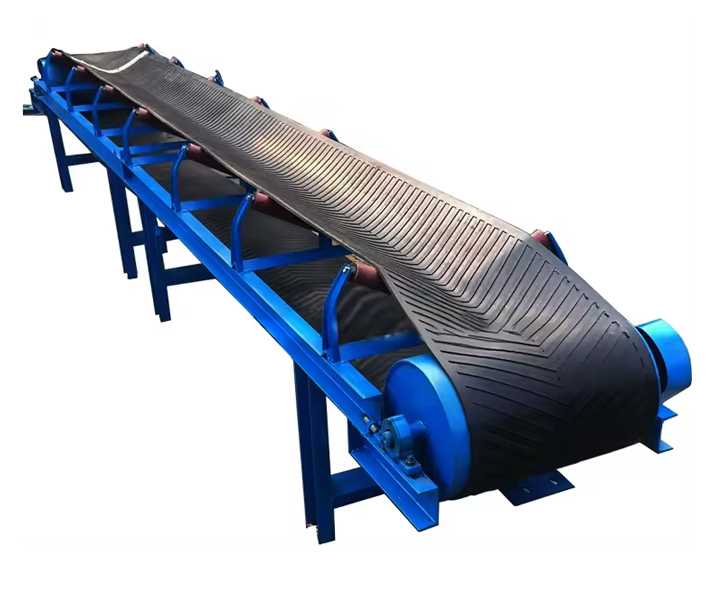

Belt Width: 500-1800mm

Height of Sidewall: 80-500mm

Belt Speed: 0.8-4.0m/s

Angle of Inclination: 30-90 degrees

Capacity: 84-5036m³/h

Application: Suitable from mining sites to processing plants or storage facilities to handle both raw coal and processed coal, such as crushed coal, pulverized coal, or coal briquettes.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

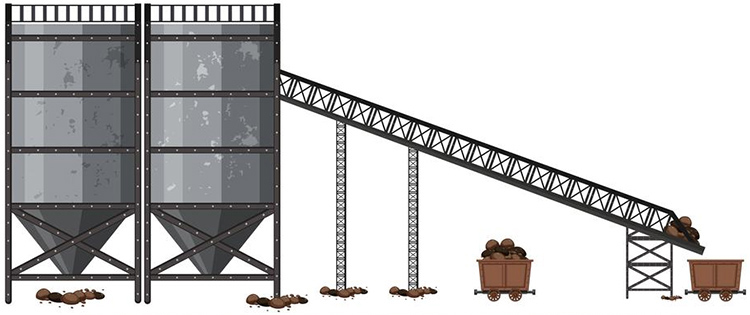

Belt conveyors for coal are used to transport coal from mining areas to processing plants or storage facilities. In power plants, they are used to transport coal from storage areas to boiler rooms for combustion. In ports, belt conveyors are used to unload coal from ships for storage or further transport.

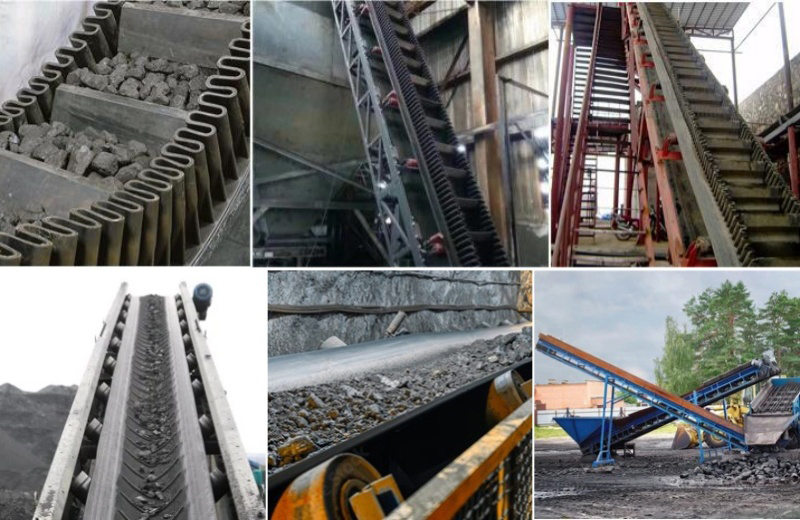

Belt conveyors for coal are designed to handle various types of coal, including bituminous coal, sub-bituminous coal, lignite, and anthracite. They can transport coal in bulk or in smaller quantities, depending on the application. Belt conveyors offer advantages such as high capacity, long-distance transportation, and the ability to handle different coal sizes and moisture contents.

There are several types of belt conveyors commonly used for coal handling in the mining and coal industries. Each type is designed to suit specific requirements and operating conditions. Here are some of the common types of belt conveyors for coal handling:

Troughed Belt Conveyors: Troughed belt conveyors have sides that are raised to form a trough, which helps contain the coal and prevent spillage. This design is especially useful for transporting bulk materials like coal over long distances and at higher capacities.

Sidewall Belt Conveyors: Sidewall belt conveyors have corrugated sidewalls that help contain the coal material and prevent it from spilling over the edges of the conveyor belt. This design is useful for handling materials with a high angle of repose or for conveying coal up steep inclines.

Incline/Decline Belt Conveyors: Incline and decline belt conveyors are designed to transport coal material at different angles. These conveyors are used to move coal up or down slopes, allowing for efficient material handling in coal processing plants or mining operations.

Belt conveyors for coal is a common and crucial conveying equipment in the coal industry and is widely used in coal production, processing and transportation.

In the coal production process, belt conveyors for coal are often used to transport coal from a mine or mining site to a processing plant or transportation site.

In the processing chain, they are used to transport coal from equipment such as crushing and screening to storage or loading areas.

Belt conveyors for coal can also be used in coal terminals, thermal power plants and other places to transport coal to ships or boilers and other equipment.

The application scenarios of belt conveyors for coal are not limited to the coal industry, but can also play a role in other industries. For example, in the construction industry, they can be used to transport coal, sand and gravel and other materials; in ports, they can be used to load and unload cargo; in the chemical industry, they can be used to transport chemical raw materials, etc.

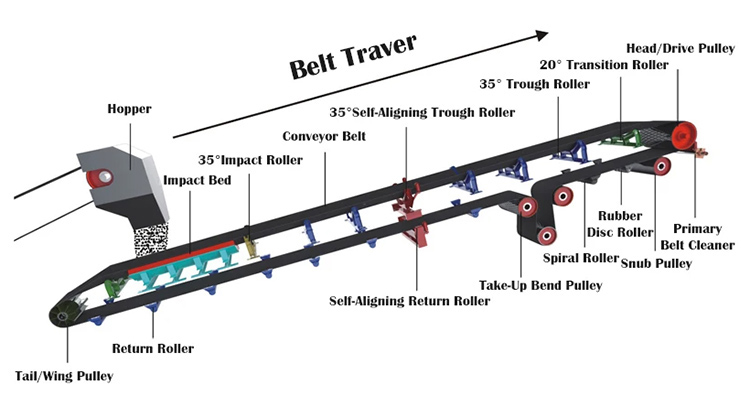

Belt conveyors for coal drives the belt to run continuously through the driving device to realize the transportation of coal and other materials. The material is loaded on the belt and due to the continuous movement of the belt, the material is transported to the destination. Support structures and rollers help maintain stable operation of the belt, while tensioners and adjusters ensure that the belt maintains proper tension and position. During the transportation process, materials can reduce friction through rollers and other components and improve transportation efficiency.

Versatility

Belt conveyors can be customized to meet specific requirements, such as inclines, declines, curves, and transfer points, making them versatile for various coal transportation applications.

Efficiency

Belt conveyors are known for their high efficiency in transporting bulk materials over long distances, making them ideal for coal transportation from mining sites to processing plants or storage facilities.

Safety

Belt conveyors are designed with safety features to prevent spillage and minimize dust emissions, ensuring a safe working environment for operators and reducing the risk of accidents.

Cost-Effective

Using belt conveyors for coal transportation can be cost-effective compared to other transportation methods, as they require less manpower and maintenance, leading to lower operational costs.

| Model | Belt Width (mm) | Lenth(m) | Belt Speed (m/s) | Lifting Height | Slope Angle | Capacity (m³/h) |

| DY-500 | 500 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 50-140 |

| DY-650 | 650 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 100-250 |

| DY-800 | 800 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 170-350 |

| DY-1000 | 1000 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 270-550 |

Belt: The conveyor belt is the essential component that carries the coal and is available in various materials and designs to suit different applications and loads.

Pulleys: Pulleys help to support and guide the conveyor belt, providing the necessary tension for efficient coal transportation.

Idlers: Idlers are rollers that support the conveyor belt and help reduce friction, ensuring smooth and reliable coal transportation.

Drive Unit: The drive unit consists of motors, gearboxes, and couplings that power the conveyor belt and control its speed and direction.

Support Structure: The support structure provides stability and strength to the conveyor system, ensuring safe and efficient coal transportation.

The conveying capacity of belt conveyors for coal depends on many factors, including bandwidth, belt speed, conveying distance, material density, etc. Generally speaking, the standard conveying capacity of belt conveyors for coal is between 50-140m³/h. For large-scale coal transportation systems, manufacturers can customize them according to customer needs, and their transportation capabilities can reach higher. Through reasonable design and selection of appropriate equipment parameters, coal transportation under different scales and requirements can be achieved to meet production needs.

A coal mine introduced a high-efficiency belt conveyor for coal to improve production efficiency. The equipment adopts an advanced control system to achieve automatic operation and monitoring. The conveyor design takes into account the characteristics of coal particles to ensure a stable and efficient transportation process. By optimizing the layout, energy consumption and maintenance costs are reduced. The belt conveyor for coal has been successfully applied to the coal mine production line, improving production efficiency, reducing labor costs.

Xinxiang Dahan is a well-known manufacturer specializing in the production of belt conveyors for coal. Dahan has advanced production equipment and a technical team, and is committed to providing customers with high-quality conveying equipment solutions. Dahan's belt conveyors for coal adopt advanced design concepts and manufacturing processes, and have the characteristics of strong stability, reliable operation, and high conveying efficiency. Manufacturers can customize production according to customer needs, and are widely used in coal mines, ports, power and other fields.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.