For transporting and handling sand, gravel and other loose materials.

![]()

![]()

Price::$800.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying capacity: 70-278m³/h

Conveying length: 10-15 meters

Conveying speed: 1.25-2.0 m/s

Application: Used in mining, construction, and agriculture to transport sand, gravel, and other loose materials.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Sand and gravel belt conveyor is a type of conveyor system specifically designed for handling and transporting sand, gravel, and other bulk materials commonly used in construction, mining, and aggregate industries. It provides an efficient and reliable method for moving large volumes of sand and gravel from one location to another.

Sand and gravel belt conveyors are commonly used in various industries, including construction, mining, quarrying, and aggregate production. They are versatile and can be customized to meet specific requirements, such as the desired capacity, length, and incline/decline angle. These conveyors facilitate the efficient transportation of sand and gravel, eliminating the need for manual handling and reducing labor costs.

Sand and gravel belt conveyor is widely used in industries and environments that need to transport sand, gravel and other bulk materials. Some common applications for gravel belt conveyors include:

Construction site: transport sand, stone, gravel, aggregate and other materials. They are used to transfer these materials from stockpiles to different areas of the construction site, including mixing plants, concrete batching plants, or directly to construction areas for backfill, embankment or other applications.

Mining and quarrying operations: used to transport mined materials from the excavation site to processing plants or storage areas. They are commonly used to move sand, gravel, ore, minerals and other bulk materials over long distances, facilitating efficient material handling and reducing reliance on trucks or other modes of transportation.

Aggregate Production: Transporting material between different stages of the production process (such as screening, crushing, washing and storage) ensures a continuous flow of material for further processing or distribution.

Sand and gravel plant: Sand, gravel and other materials can be transported between different processing equipment (such as crushers, screens, washing machines and storage bins), thereby simplifying the production process and optimizing efficiency.

Efficient Material Handling

Sand and gravel belt conveyors streamline material handling processes, reducing manual labor and increasing operational efficiency.

Cost-Effective Transport

By automating the transport of sand and gravel, belt conveyors help reduce labor costs and minimize material spillage, leading to cost savings for businesses.

Versatility

Sand and gravel belt conveyors can be used in a variety of applications, including mining operations, construction sites, aggregate processing plants, and more, making them versatile tools for material transport.

Reduced Downtime

Reliable sand and gravel belt conveyors help minimize downtime by ensuring continuous material flow, thereby improving overall productivity and operational efficiency.

Cost-Effective Transport

By automating the transport of sand and gravel, belt conveyors help reduce labor costs and minimize material spillage, leading to cost savings for businesses.

Stable and reliable

The operation is stable and reliable, reducing material loss and failure rate, ensuring continuous production.

The working principle of the sand and gravel belt conveyor is to drive the conveyor belt through a belt transmission device to make it run continuously along the set conveying line. Granular materials such as sand and gravel are placed on the conveyor belt, and as the conveyor belt moves, the materials are taken to the destination. Supports, rollers and tensioners ensure stable operation of the conveyor belt, while the drive provides the power.

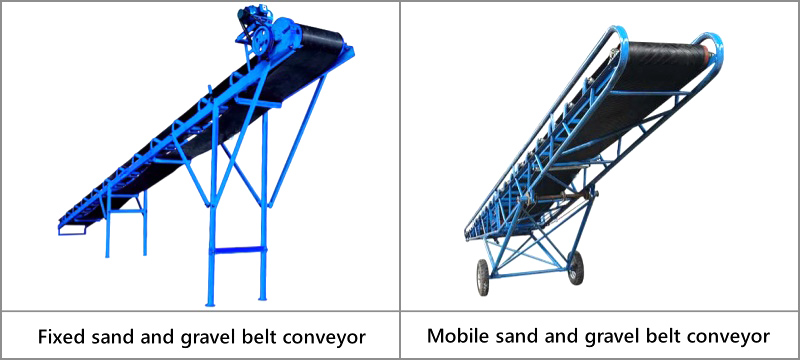

Sand and gravel belt conveyors can be divided into the following types according to different conveying angles and installation design functions:

Classification from different conveying angles:

Horizontal sand and gravel belt conveyor: Mainly used for horizontal sand and gravel conveying, suitable for horizontal sand and gravel transportation in mines, construction sites and other places.

Inclined sand and gravel belt conveyor: Used to convey sand and gravel at an inclined angle, suitable for places that need to cross height differences, such as sand and gravel conveying from the ground to the stockpile yard.

Vertical sand and gravel belt conveyor: Suitable for places where sand and gravel need to be conveyed in a 90° vertical direction, and can achieve vertical lifting or lowering of sand and grave.

Classification from different installation methods:

Fixed sand and gravel belt conveyor: Fixed sand and gravel belt conveyor is installed in a fixed position for long-term or permanent conveying tasks, suitable for fixed production lines or sites, and the conveying direction and position are fixed.

Mobile sand and gravel belt conveyor: Mobile sand and gravel belt conveyor is mobile and can be freely moved and arranged as needed. It is suitable for occasions where the conveying position needs to be changed frequently or for temporary projects.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | >15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

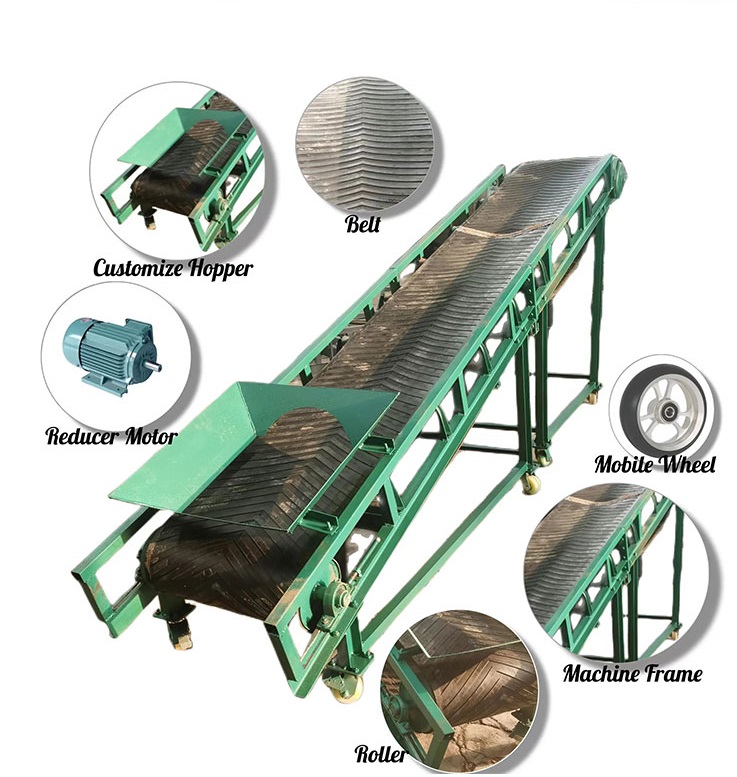

Sand and gravel belt conveyors can be customized to meet specific material handling needs by:

Belt width and length: The belt width and length can be customized to suit the required material flow rate and the distance the material needs to be transported.

Inclining/declining angle: The inclining or descending angle of the conveyor can be adjusted to suit site layout and material handling requirements. Steeper angles are suitable for conveying material up or downhill, while flatter angles are suitable for horizontal conveyance.

Belt material and design: The choice of belt material depends on the characteristics of the conveyed sand and gravel. For example, a conveyor handling abrasives may require a belt with high wear resistance. Belt designs can also be customized to include cleats, sidewalls or chevron patterns to prevent material spillage or improve belt grip.

Loading and unloading mechanism: Customized loading and unloading mechanism can be incorporated into the conveyor system to optimize material transfer. These mechanisms may include hoppers, chutes or gates to facilitate controlled and efficient loading and discharge of sand and gravel.

Conveyor belt speed and control: The speed of the conveyor belt can be adjusted to match the required material flow and operation requirements. Variable speed drives or control systems can be employed to precisely control conveyor speed, allowing for efficient material handling and minimizing spillage.

Additional features: a cover or case can be installed to contain dust or prevent material contamination. Impact beds, skirt systems or seals can be added to minimize material spillage and ensure efficient operation.

A construction materials company uses sand and gravel belt conveyor to efficiently transport sand and gravel aggregates. The equipment is installed between the material yard and the production line, which significantly improves the conveying efficiency and reduces the cost of manual handling. The stability and durability of the conveyor make the production process more continuous and smooth, reducing equipment failures and downtime. Customer feedback shows that the equipment not only improves production efficiency, but also reduces operating costs, significantly improving the company's competitiveness.

Xinxiang Dahan is a professional manufacturer dedicated to producing high-quality sand and gravel belt conveyor. Their products feature durable materials and advanced technology and are suitable for loose material handling in mining, construction, agriculture and other industries. Xinxiang Dahan is known for its reliability, efficiency and flexibility, providing customers with customized solutions to meet various material handling needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.