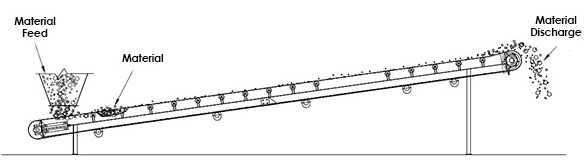

Rubber Belt Conveyor for Coal is a kind of conveying equipment commonly used in coal mining and processing. It transports coal and other materials from one location to another through a conveyor belt. It can be transported horizontally or inclined. It is widely used in coal mines, thermal power plants, ports and other places to transport granular materials such as coal and ore.

Rubber Belt Conveyor for Coal usually consists of the following main parts:

Conveyor belt: The conveyor belt is the core component of the coal belt conveyor, which is used to carry and transport materials.

Drive device: The drive device provides power to drive the conveyor belt to run. It is usually a system composed of a motor, a reducer, a coupling, etc.

Roller: The roller supports the conveyor belt and keeps it on the correct running track.

Tensioning device: The tensioning device is used to adjust the tension of the conveyor belt to ensure that the conveyor belt maintains a proper tension state during operation to prevent sliding and falling off.

Supporting device: The supporting device supports the conveyor belt and other components to ensure that the overall structure of the conveyor is stable and reliable.

Cleaning device: It is used to remove debris and accumulation on the conveyor belt, keep the surface of the conveyor belt clean, and avoid damage to the conveyor belt and equipment.

Protective device: A safety device used to protect the conveyor, including a protective cover, a safety switch, etc., to ensure the safety of operators and equipment.

The Rubber Belt Conveyor for Coal can efficiently transport materials such as coal from one location to another through the following steps, improving production efficiency and reducing labor intensity.

Loading: Coal is evenly distributed on the running belt through the feeding device.

Conveying: The belt moves continuously under the action of the driving device to transport the coal to the designated location.

Unloading: After the coal reaches the unloading point, it is unloaded through the unloading device.

Coal belt conveyor has many advantages, making it one of the commonly used conveying equipment in the coal industry. The following are the main advantages of coal belt conveyor:

Large conveying capacity: With large conveying capacity, it can efficiently convey large amounts of coal and other materials.

Reliable operation: The coal belt conveyor has a simple structure and stable and reliable operation, which reduces equipment failures and downtime and improves production continuity.

Strong adaptability: The coal belt conveyor is suitable for various environments and working conditions. It can convey coal and other granular materials horizontally, inclined, and vertically, and has a wide range of applications.

Reduced pollution: The coal belt conveyor adopts closed conveying, which reduces the scattering of materials and dust pollution.

A mining company needed a reliable and efficient way to transport large quantities of coal from a mine to a nearby processing plant. They chose the rubber belt conveyor system for its durability, low maintenance requirements and high capacity.

Rubber belt conveyor for coal the conveyor system consists of a series of rubber belts driven by electric pulleys that carry the coal along a series of rollers and idlers. The conveyor system is designed to move 3,000 tons of coal per hour over a distance of more than 10 kilometers.

Rubber belt conveyor systems are built to handle the harsh operating conditions of mining environments, including exposure to dust, dirt and moisture. The conveyor system requires minimal maintenance and is capable of continuous operation, ensuring mining companies maximize uptime and productivity.

Rubber belt conveyor systems also provide mining companies with a cost-effective solution as it is able to transport large quantities of coal over long distances with minimal energy consumption. The conveyor system also reduces the need for manual labor, improving worker safety and reducing labor costs.

Overall, the use of rubber belt conveyor systems in the mining industry provides a reliable, efficient and cost-effective means of transporting large quantities of coal over long distances, helping mining companies increase productivity, reduce costs and improve worker safety.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.