In the realm of coal handling and transportation, the capacity of belt conveyors plays a pivotal role in ensuring the efficient movement of bulk materials from one point to another.

The capacity calculation formula of belt conveyor for coal is:: Conveying capacity (t/h) = belt speed (m/s) × bandwidth (mm) × layer density (t/m3) × efficiency (%)

Among them, the belt speed refers to the running speed of the conveyor belt on the belt conveyor, usually in meters and seconds; the bandwidth refers to the effective width of the conveyor belt, in millimeters; the material layer density refers to the density of the conveyed material on the conveyor belt , in tons cubic meters; efficiency refers to the efficiency of the conveyor, usually expressed as a percentage.

1. Belt width: The width of the belt affects the carrying capacity of the conveyor. Generally speaking, wider conveyor belts can carry more coal than narrower conveyor belts.

2. Belt speed: The speed at which the belt moves also affects the capacity of the conveyor. Higher belt speeds allow more coal to be transported in a given time.

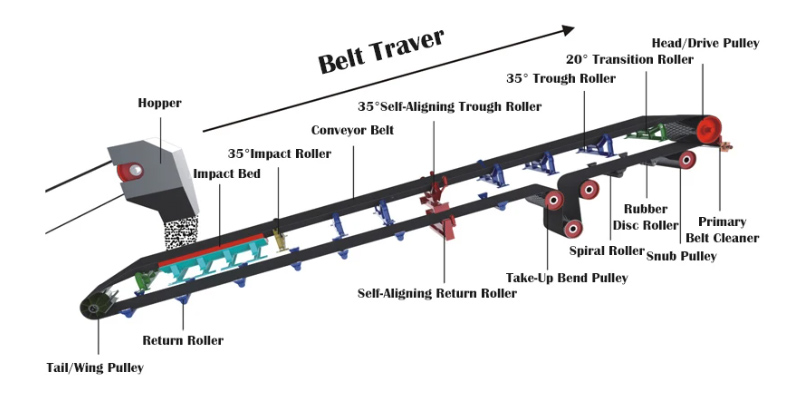

3. Belt trough: The design of the belt conveyor (such as the presence of trough rollers or cleats) can affect capacity. Troughed conveyor belts and wedge conveyor belts can increase capacity by providing a better seal and preventing spillage.

4. Conveyor length: The length of the conveyor determines its capacity. Longer conveyors generally have higher capacities because they can transport coal over greater distances.

5. Incline/drop angle: If the conveyor tilts or drops, it will affect the capacity. Inclined conveyors may have reduced capacity compared to horizontal conveyors due to additional resistance and potential material slippage.

6. Material characteristics: The physical characteristics of coal, such as size, density and flowability, will affect the capacity of the conveyor. For example, larger coal sizes may require wider conveyor belts or lower conveyor speeds to maintain proper flow and prevent clogging.

7. Loading and unloading conditions: Loading and unloading methods and the equipment used will affect the capacity of the conveyor. An efficient loading and unloading system ensures that coal is evenly distributed on the belt and discharged correctly, maximizing conveyor capacity.

It is important to note that the capacity of a belt conveyor is typically expressed in terms of mass or volume per unit time (e.g., tons per hour or cubic meters per hour). The specific capacity of a belt conveyor for coal will depend on the specific operational conditions and design parameters mentioned above.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.