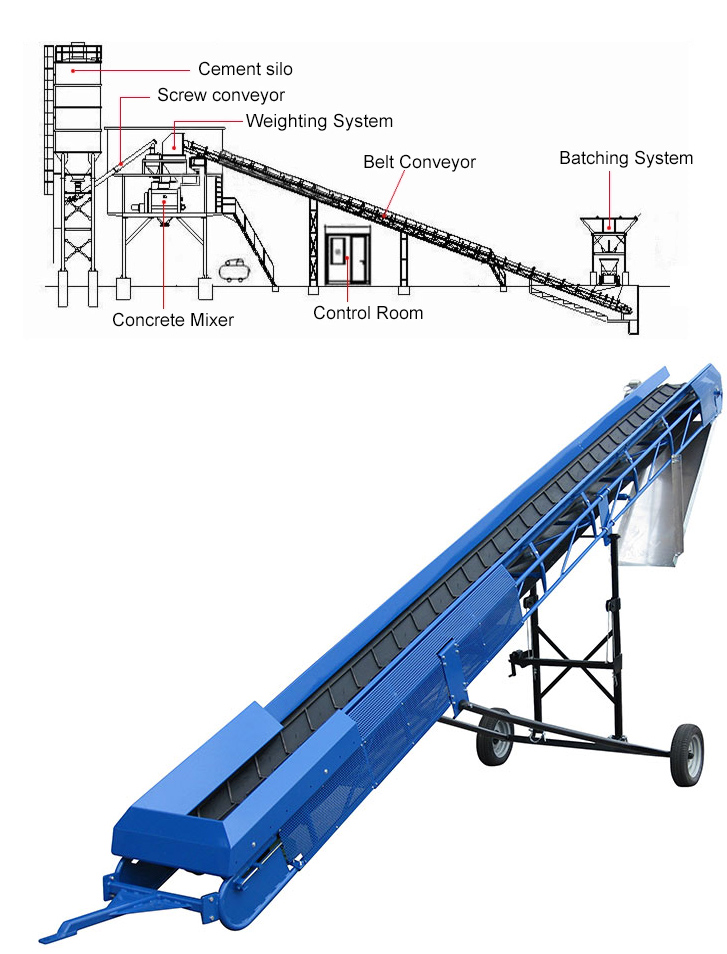

Conveying systems designed specifically for the cement industry to transport cement and other bulk materials.

![]()

![]()

Price:$800.00-$7,000.00/Set

Consult now and enjoy a 10% discount

Belt Width: 500-1800mm

Height of Sidewall: 80-500mm

Belt Speed: 0.8-4.0m/s

Angle of Inclination: 30-90 degrees

Capacity: 84-5036m³/h

Application: Used to transport various materials in the cement production process, including limestone, clay, gypsum, coal and finished cement.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

A belt conveyor for cement is a type of conveyor system specifically designed for handling cement and other bulk materials in the cement industry. It plays a crucial role in the transportation of cement from one location to another within a cement plant or for transferring cement from a production facility to storage or distribution areas.

Belt conveyors are capable of handling large quantities of bulk materials, making them suitable for transporting cement in bulk from one location to another. They can move materials horizontally, vertically, or at inclined angles, depending on the plant layout and operational requirements.They contribute to the smooth operation of cement plants, increase productivity, reduce manual labor and optimize material handling processes.

There are several types of belt conveyors used in the cement industry, each designed for specific applications and material handling requirements. Here are some common types:

1、Troughed Belt Conveyors: Troughed belt conveyors have a V-shaped or troughed belt that helps contain and transport bulk materials. The troughed design prevents material spillage and provides better support for the belt, making it suitable for conveying bulk cement, limestone, and other granular materials.

2、Sidewall Belt Conveyors: Sidewall belt conveyors feature sidewalls that are attached to the belt, forming a pocket to contain and transport bulk materials. These conveyors are particularly useful for handling materials with a high angle of repose or for conveying materials up steep inclines or around curves.

In a cement plant, belt conveyors play a crucial role in transporting various materials throughout the production process. Here are some key applications of belt conveyors in a cement plant:

1.Raw Material Handling: Belt conveyors are used to transport raw materials such as limestone, clay, shale, and iron ore from the quarry or mines to the crushers or storage areas.

2.Cement Production: Belt conveyors are employed in various stages of cement production. They transport the crushed raw materials, such as limestone and clay, to the pre-blending or raw mill area. Additionally, belt conveyors are used to transfer the ground cement clinker from the ball mill or vertical roller mill to the storage silos.

3.Bulk Material Transport: Belt conveyors are utilized for the transportation of bulk cement, fly ash, and other powdered or granular materials to storage silos or directly to the cement trucks for distribution.

4.Cement Packaging: Belt conveyors are involved in the packaging process of cement. They transport cement bags from the packaging machine to the palletizing area or directly to the loading docks for distribution.

5.Waste Handling: Belt conveyors are used for handling waste materials generated during the cement production process. They transport materials such as kiln dust, filter cake, and other by-products to designated disposal areas or recycling facilities.

Transporting Bulk Materials

Belt conveyors are capable of handling large quantities of bulk materials, making them suitable for transporting cement in bulk from one location to another. They can move materials horizontally, vertically, or at inclined angles, depending on the plant layout and operational requirements.

Efficiency and Automation

Belt conveyors offer high efficiency and automation capabilities, allowing for the smooth and continuous transport of cement. They can be integrated with control systems to automate the material flow, optimize production rates, and minimize manual intervention.

Long Distances and High Capacities

Belt conveyors in cement plants can cover long distances, to connect different processing units, storage areas, and loading/unloading points. They have high conveying capacities, enabling the efficient movement of large volumes of cement and other materials.

Durability and Reliability

Belt conveyors used in the cement industry are designed for heavy-duty applications and harsh environments. They are built to withstand the abrasive nature of cement and other materials, ensuring durability and reliability in continuous operation.

Belt conveyor for cement is a conveyor specifically designed to transport cement, while other conveyors can also be used to transport cement, but they may be suitable for different industries or specific applications. The following are some differences between "Belt conveyor for cement" and other conveyors in conveying cement:

1. Design: Belt conveyor for cement is usually designed according to the needs of the cement industry, taking into account the special properties and requirements of cement. It may have special dustproof and sealing designs to reduce the leakage of cement dust. Other conveyors, on the other hand, may be general-purpose designs suitable for handling a wide range of materials.

2. Wear resistance: Cement is a highly abrasive material, so "belt conveyor for cement" usually has stronger wear resistance. It may use special conveyor belt materials or maintenance designs to extend service life and Reduce maintenance requirements.

3. Sealing: Cement will generate dust during transportation, so "belt conveyor for cement" may have better sealing performance to reduce dust leakage. This helps to improve the cleanliness of the working environment and the health and safety of employees.

4. Capacity and speed: Cement production usually requires a large amount of conveying capacity, so the belt conveyor for cement may have higher conveying capacity and speed to meet the production requirements of the cement factory.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

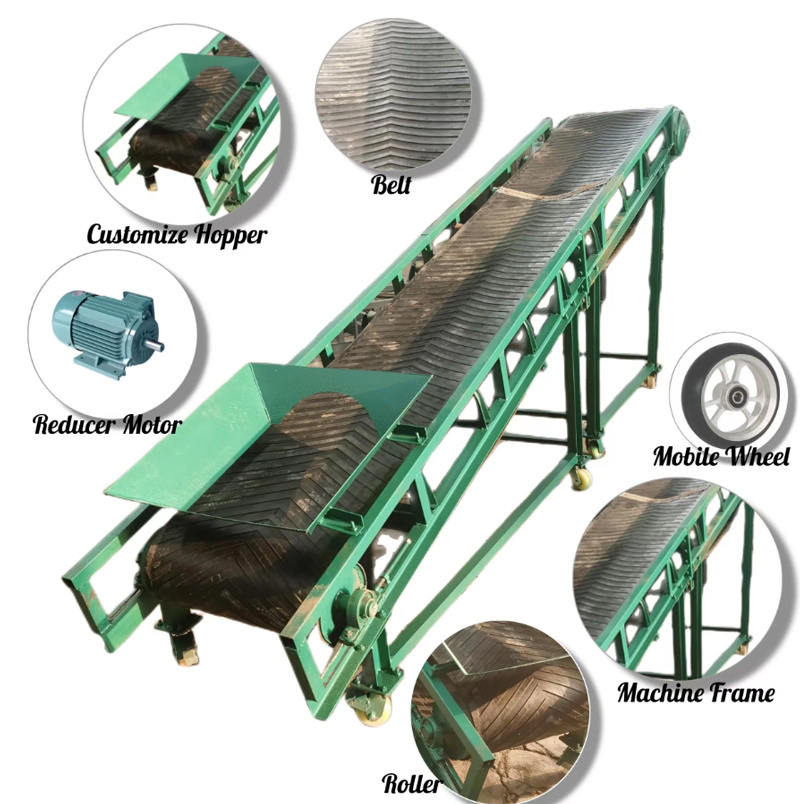

Belts: Belts are an important part of the conveyor system that carries materials. In cement plants, conveyor belts are typically made of durable materials that can withstand the wear and tear of cement and other bulk materials.

Pulleys: Pulleys are used to support and guide the belt, helping to maintain proper tension and alignment. They are vital to the smooth operation of conveyor systems.

Rollers: Rollers are installed along the length of the conveyor belt to support and guide the conveyor belt as it moves. They reduce friction and promote smooth movement of materials.

Drive system: The drive system consists of motors, gearboxes and other components that provide the power needed to move the conveyor belt. It is essential for controlling the speed and direction of the belt.

Support Structure: The support structure provides a stable framework for the conveyor system, ensuring correct alignment and stability during operation.

1.Daily Inspections: Perform visual inspections of the conveyor system every day before operation. Check for any signs of damage, misalignment, or abnormal noise. Look for debris or spillage on the belt and ensure all safety guards are in place.

2.egular Lubrication: Lubricate the conveyor components, such as bearings, pulleys, and chains, according to the manufacturer's recommendations. Proper lubrication helps reduce friction and wear, extending the life of the components.

3.Weekly or Monthly Inspections: Conduct more detailed inspections on a weekly or monthly basis. Inspect the belt for signs of wear, tears, or damage. Check the belt tension and adjust if necessary. Examine the pulleys, rollers, and idlers for proper alignment and any signs of wear or damage. Inspect the motor and drive components for any issues.

| Convey products | Purpose of usage | Conveying capacity | Conveying length |

| Limestone, clay, iron ore | Raw materials are delivered to the crusher | 10t/h | 5 m |

| Coal grinding machine pulverized coal | Pulverized coal is delivered to the burner | 5t/h | 20 m |

| Cement clinker | Clinker is transported to storage bin | 8t/h | 15m |

| Cement | Cement delivered to concrete mixer | 10t/h | 10m |

| Fly ash | Fly ash is transported to storage bin | 20t/h | 4m |

| Scrap | Transport waste to waste disposal area | 20t/h | 18m |

Xinxiang Dahan is a professional cement conveyor manufacturer. They offer high quality belt conveyors specifically for applications in the cement industry. These conveyors feature advanced design and manufacturing technology to ensure efficient and reliable cement delivery. Xinxiang Dahan's products have the characteristics of strong wear resistance, good sealing, and adaptability to large conveying volumes and long conveying distances. They are committed to providing customized conveying solutions for cement plants and meeting customer needs through strict quality control and excellent after-sales service.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.