Z-type bucket elevator for dried fruit materials is a device specially used for conveying dried fruits (such as cashews, almonds, walnuts, etc.) vertically or obliquely. It adopts a Z-type layout to lift dried fruits from low to high through the hopper, which is suitable for the material conveying link in the dried fruit processing production line.

① Reduce material breakage and protect fragile nuts such as cashews, almonds, pistachios, etc.

② Closed conveying, in line with food-grade hygiene requirements, to avoid contamination.

③ Can be matched with other equipment to achieve fully automatic production and improve efficiency.

④ The conveying height and speed can be customized to meet different process requirements.

Material loading: Dried fruits and other materials are loaded by the bucket, and the bucket is transported upward with the movement of the chain or pulley.

Vertical lifting: The bucket is lifted vertically along the Z-type structure under the traction of the chain or pulley to convey the material from the bottom to the top.

Unloading: After reaching the top, the material is unloaded to the next processing stage or equipment.

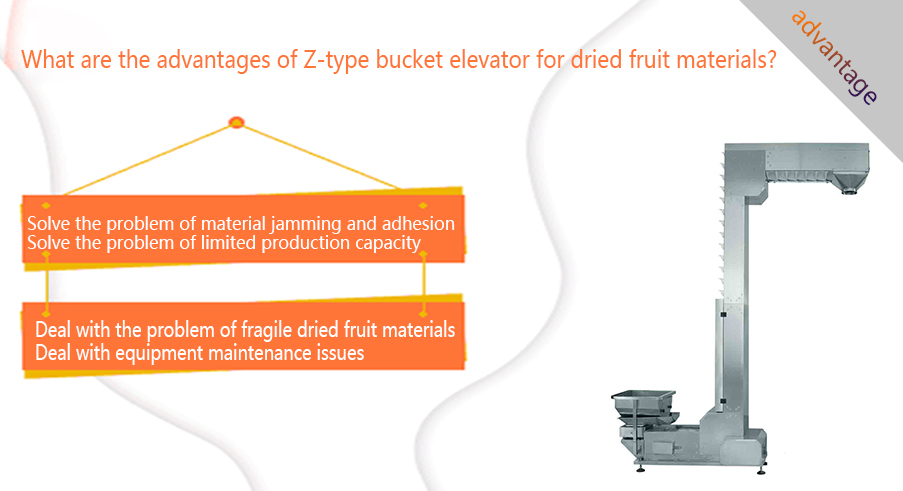

1. Solve the problem of material jamming and adhesion: Some seasoned dried fruits (such as honey cashews, caramel almonds) have syrup and seasoning powder on the surface, which are easy to stick to the hopper and block the discharge port during transportation. The hopper of the Z-type bucket elevator for dried fruit materials adopts a flip-type unloading structure to avoid material residue.

2. Solve the problem of limited production capacity: Some traditional conveying equipment has a slow speed when conveying high-load materials. The Z-type bucket elevator for dried fruit materials can choose a single outlet/multiple outlet structure to adapt to multiple production lines.

3. Deal with the problem of fragile dried fruit materials: Z-type bucket elevator for dried fruit materials adopts low-speed conveying and flexible hopper. The material enters slowly from the feed port without violent collision, reducing broken fruit.

4. Deal with equipment maintenance issues: Traditional belt conveyors and screw conveyors are prone to wear after long-term operation, while Z-type bucket elevator for dried fruit materials adopts wear-resistant chains and food-grade hoppers with long service life.

|

Parameters |

recommended range |

description |

|

Lifting height |

2-6meters(customizable) |

choose the appropriate height according to the needs of the production line |

|

Conveying capacity |

1-10tons/hour |

affects production efficiency, needs to match production capacity |

|

Hopper material |

food-grade PP hopper/stainless steel |

ensure food safety, corrosion resistance |

|

Body material |

carbon steel spraying /304 stainless steel |

carbon steel is suitable for ordinary materials, stainless steel is suitable for food-grade requirements |

|

Drive mode |

chain drive |

stable operation, suitable for long-term work |

|

Control mode |

variable frequency speed regulation /switch control |

adjustable conveying speed to match different production rhythms |

Z-type bucket elevator plays an important role in the transportation of dried fruit materials and is widely used in food processing, food packaging, feed production and other industries. Z-type bucket elevator is widely used in automated production lines in the dried fruit industry, for example:

① Lifting dried fruit from a low place to a packaging machine or color sorter.

② Achieve uniform feeding in a multi-point batching system.

③ Cooperate with a fully automatic weighing and packaging system to improve production efficiency.

✅Prevent overload: Excessive feeding may cause the bucket to get stuck and affect operation.

✅Regular cleaning: Dried fruit materials are prone to debris, and the inside of the equipment needs to be cleaned regularly to avoid material accumulation.

✅Check the chain tension: After long-term operation, the chain may loosen, and the tension needs to be adjusted regularly to maintain smooth transportation.

✅Select dust cover: In a dusty processing environment, a dust cover can be installed to prevent dust from contaminating the material.

Z-type bucket elevator for dried fruit materials is an efficient and flexible conveying equipment, which is particularly suitable for vertical or inclined conveying needs in the dried fruit processing industry. Through reasonable selection and regular maintenance, production efficiency can be significantly improved, and the integrity and sanitation and safety of dried fruit materials during transportation can be ensured.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.