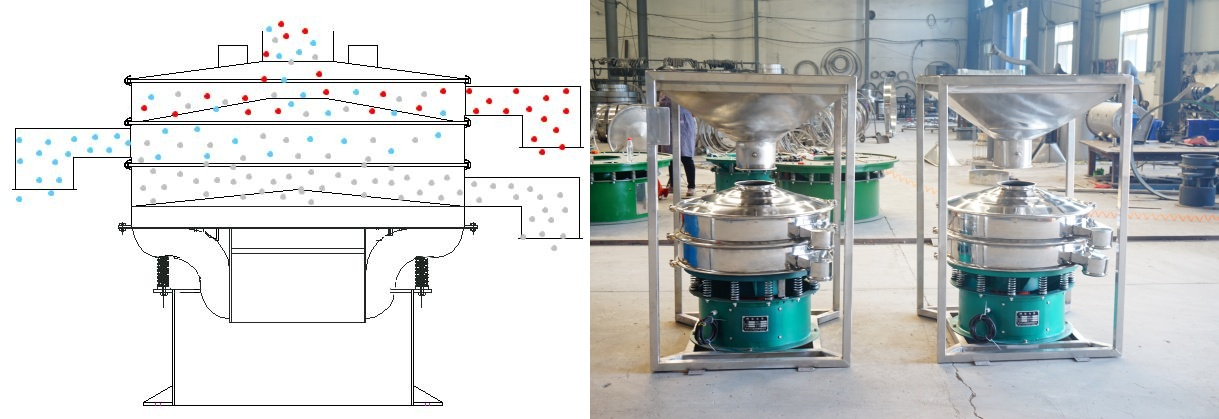

Binding rotary vibrating screen is a screening device that combines a silo with a vibrating screen. It adds a silo structure to the vibrating screen to store the material to be screened, and realizes continuous or intermittent automatic feeding. This design improves the screening efficiency, can effectively handle impurities in granular materials or perform particle size separation, reduces manual operation, and is widely used in chemical, food, pharmaceutical, metallurgical and other industries.

1. Powdered materials

Applicable materials: iron ore powder, coal powder, flour, starch, chemical powder, etc.

Features: Powder has good fluidity but is easy to generate dust. The closed design of binding rotary vibrating screen can effectively control dust

Application scenario: Screening to 200 mesh before discharging iron ore powder from the silo

2. Granular materials

Applicable materials: copper ore sand, rice, PE, PP granules, urea, compound fertilizer, etc.

Features: The granules have strong fluidity. Binding rotary vibrating screen can be equipped with a coarse mesh screen (such as 10-50 mesh) for rapid separation.

Application scenario: Screening of coarse and fine ore particles in the silo of the beneficiation plant

3. Viscous or wet materials

Applicable materials: concentrate after beneficiation, clay powder, wet coal powder, etc.

Features: Viscous materials are easy to clog the screen. Binding rotary vibrating screen can be equipped with bouncing balls, etc.

Application scenario: Screening of wet iron ore powder in the silo of the beneficiation plant

4. Slurry or liquid materials

Applicable materials: ore pulp, paint, juice, soy milk, etc.

Features: Binding rotary vibrating screen can be equipped with a fine mesh (such as 300-500 mesh), which is suitable for screening a small amount of liquid.

Application scenario: Filter the ore pulp before the silo of the ore dressing plant to remove large particles of sediment.

Binding rotary vibrating screen generates three-dimensional motion through the eccentric hammer on the vibrating motor. The material moves in a spiral shape on the screen surface. Small particles fall into the lower layer through the screen, and large particles or impurities are discharged from the discharge port. Adjusting the phase angle of the upper and lower eccentric blocks can change the material movement trajectory to meet different screening needs.

1. Dealing with the problem of impurities in materials: During the transportation and storage of materials, impurities may be mixed into the materials. Binding rotary vibrating screen can separate materials of different particle sizes.

2. Solving the problem of insufficient material processing capacity: Some materials have a large processing volume, resulting in slow screening speed or inability to process a large amount of materials in time. Binding rotary vibrating screen has a high processing capacity and a fast screening speed, which is suitable for screening large-scale materials.

3. Dealing with material deposition and accumulation problems: Some materials are prone to deposition or accumulation at the bottom of the silo, resulting in failure to transport smoothly. Binding rotary vibrating screen displaces the material through vibration, reduces accumulation, and ensures that the material flows smoothly into the screening equipment.

4. Solving the problem of uneven material distribution: The material may be unevenly distributed on the screen due to uneven feeding or accumulation of materials in the silo. Binding rotary vibrating screen makes the material evenly distributed on the screen surface, improving screening efficiency and accuracy.

|

Model |

Screen diameter (mm) |

Number of screening layers (layers) |

Motor power (kW) |

Silo volume (L) |

Applicable materials |

|

DH-600 |

600 |

1-3 |

0.25-0.55 |

50-100 |

Powder, granular materials |

|

DH-1000 |

1000 |

1-4 |

0.75-1.1 |

100-200 |

Powder, granular materials |

|

DH-1500 |

1500 |

1-5 |

1.5-2.2 |

200-300 |

Large-volume powder, granular materials |

1. Screening of iron ore powder silo: Before the iron ore powder is discharged from the silo, binding rotary vibrating screen can be used to remove large particles of impurities or classify them into different particle sizes to ensure the uniform quality of the iron ore powder entering the subsequent process (such as sintering or magnetic separation) and improve efficiency.

Parameter example: 200 mesh screen, 50-100 t/h lifting capacity, 1.5-3 kW motor power.

2. Grain storage cleaning: Before grain (such as rice and wheat) enters the warehouse, binding rotary vibrating screen can screen out dust, shells and other impurities to improve storage quality and prevent mold or pests.

3. Chemical raw material classification: Resin powder, pigments, etc. are stored in the silo. Binding rotary vibrating screen needs to be used after classification according to particle size. Ensure product consistency and reduce production defects.

Binding rotary vibrating screen is a very effective material screening tool, suitable for grading and cleaning of various types of granular materials, especially in industries that need to improve screening efficiency and reduce impurities, such as chemicals, mining, food and pharmaceuticals.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.