Ideal for separation and dedusting of dry, powdered and granular products

![]()

![]()

![]()

Price:$860.00-$3,680.00/set

Consult now and enjoy a 10% discount

Diameter: 600-2600mm

Feed rate: 1kg/h - 50t/h

Mesh: 20 microns - 20 mm

Number of sieve plates: 1-5 layers

Amplitude: 40-80 mm horizontally and 5-40 mm vertically

Acceleration: 1,3-1,8 g

Low-frequency screening imitating manual shaking can effectively reduce the breakage of fragile materials.

Application:The perfect reliable solution for the precise separation of class 1-6 powders and granules, especially for fine and difficult screening applications, for feed rates from 10 kg/h to 40 t/h.

Commitment:

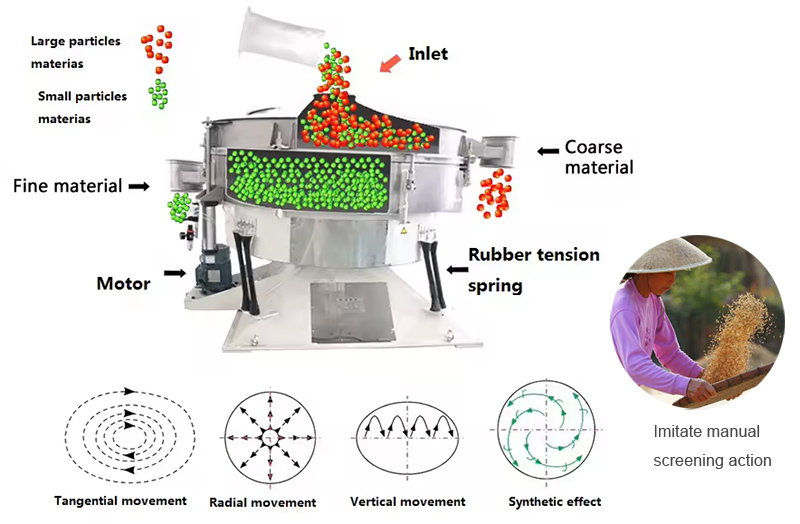

Swing vibrating screen is an effective principle of simulating the motion of artificial screening at present. It has rotating and swinging vibration. The particles of different sizes are screened through different layers of screens and then discharged from different outlets. The screening accuracy is as high as 95%. Above, the efficiency is super high, the life of the screen is more than 3 times that of conventional screening equipment, and the output is also 3-5 times that of ordinary screening equipment. Compatible with all fine and ultra-fine ranges of powder and particulate materials, especially suitable for difficult to handle and high-volume materials.

Circular Swing Vibrating Screen

Imitating manual screening, materials will be shaken and scattered on the screen and thrown upward and downward slightly. The screening efficiency is generally 93% to 95%. It is suitable for a variety of applications, including classification, exfoliation and dehydration.

Square Swing Vibrating Screen

The reciprocating rotary motion quickly disperses materials. It adopts a multi-layer "duplex" design, allowing one to be used in multiple vibrating screens, which is several times the processing capacity of traditional vibrating screens.

Allstainless steel swing vibrating screen: Made of stainless steel, it has the advantages of corrosion resistance and easy cleaning. It is suitable for industries with high hygiene requirements such as food and medicine.

Contact part stainless steel swingvibrating screen: Contact part of the vibrating screen is made of stainless steel, such as screen mesh, screen frame, etc., while other non-contact parts are made of carbon steel or other materials. It is suitable for occasions where product hygiene requirements are high but costs need to be reduced.

Allcarbon steel swing vibrating screen: Made of carbon steel, it has high strength and wear resistance and is suitable for general industrial fields. The price is relatively low and suitable for use in situations where material requirements are not high.

The swing vibrating screen works by using a motor to drive the screen surface back and forth in a circular motion. This motion causes the material on the screen surface to move in a spiral pattern. As the material moves, the smaller particles fall through the screen openings, while the larger particles are conveyed to the discharge end of the screen.

The swing motion of the screen helps to prevent particles from sticking to the screen surface. This is because the particles are constantly being lifted and moved around, which prevents them from forming a bond with the screen.

High screening efficiency

Effectively imitating the action and process of manual screening, the material presents an involute spiral trajectory on the screen surface, making the material travel a relatively long distance on the relative area, achieving 6-level separation, and the screening accuracy is as high as 90%-95 %.

High yield

Soft rock screening, no high-speed vibration, no damage to the original particle structure of the material, not easy to generate static electricity, more suitable for screening flammable, explosive and easy to generate static electricity materials.

The mesh is not clogged

Bouncing ball, ultrasonic wave, and drum brush are optional cleaning devices. Various anti-blocking technologies make the sieve holes not easy to block, which is beneficial to improve screening accuracy and screening output.

Multi-layer screening

The effective screening area of each layer is 0.28-6.4㎡, up to 5 layers can be used, and it can provide grading of 6 kinds of products with different specifications.

Long lasting

Working with low frequency and small load, the acceleration is 4-5 times lower than that of the vibrating screen, which makes the screen not easy to damage and prolongs the service life of the screen.

Low working noise

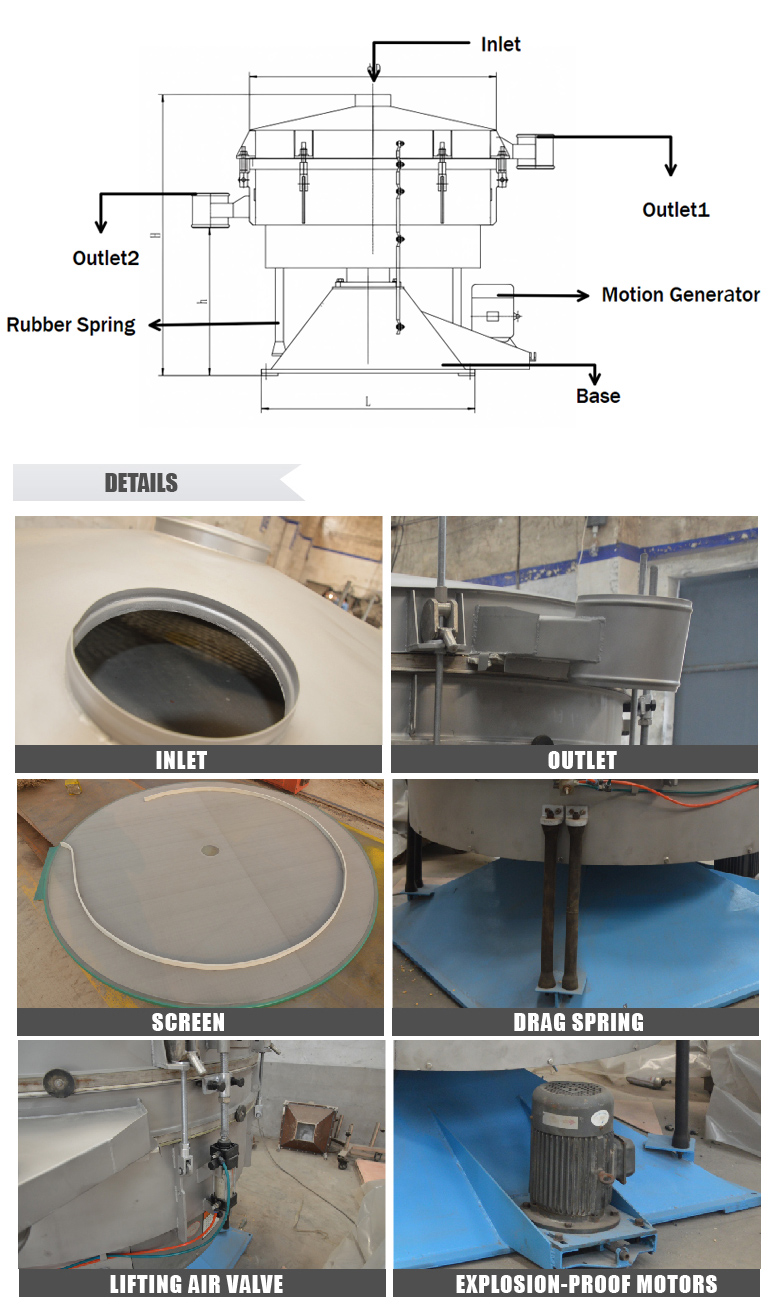

Internal sealing, airtightness up to 50 mPa, rubber tension spring left and right tension support, good shock absorption and buffering effect, working noise as low as 75 decibels.

| Swing Vibrating Screen | Ordinary Vibrating Screen |

| Elliptical Swing (simulates artificial) | High-speed vibrating screening material |

| no damage material | Potential to destroy material |

| Accuracy up to 95% | Accuracy 50%-95% (different materials) |

| Less wear and tear without beating | Beating the screen surface, the screen mesh is greatly worn |

1. The Swing vibrating screen is more suitable for irregular or wet materials within 500 mesh due to the artificial screening and the addition of a net cleaning device, which overcomes the risk of blocking the screen of ordinary vibrating screens, and the vibrating screen belongs to unbalanced damage. Violent movement uses the principle of vibration to screen materials, so sometimes the materials are destroyed. Therefore, for some ">granular crystals and brittle materials, it is recommended to use swing screen, and its screening accuracy can reach more than 95%.

2. For the materials above 30 mesh, the output of the vibrating screen and the swing vibrating screen are basically the same. For the raw materials from 30 mesh to 500 mesh, the output of the swing screen is much higher than that of the vibrating screen, which is generally a vibrating screen. 5-10 times.

| Model | YB600 | YB1000 | YB1200 | YB1600 | YB2000 | YB2600 |

| Dia. | 650 mm | 1040 mm | 1250 mm | 1580 mm | 1880 mm | 2650 mm |

| Screening area | 0.29M2 | 0.76 M2 | 1.1 M2 | 1.8 M2 | 2.6 M2 | 5.3 M2 |

| space requirement | 0.4 M2 | 1.8 M2 | 2.5 M2 | 3.9 M2 | 5.6 M2 | 9.6 M2 |

| Layers | 1-5 | |||||

| Power | 0.25 KW | 1.5 KW | 2.2 KW | 3.0 KW | 4.0 KW | 5.5 KW |

| Machine base | 630 mm | 900 mm | 1100 mm | 1340 mm | 1340 mm | 1940 mm |

| Height of single layer | 830 mm | 1155 mm | 1480 mm | 1480 mm | 1500 mm | 1580 mm |

| Weight of single layer | 140 KG | 490 KG | 700 KG | 980 KG | 1050 KG | 1900 KG |

| Height of 2 layers | 965 mm | 1280 mm | 1640 mm | 1640 mm | 1660 mm | 1710 mm |

| Weight of 2 layers | 155 KG | 535 KG | 770 KG | 1060 KG | 1140 KG | 2000 KG |

| Height of 3 layers | 1080 mm | 1400 mm | 1800 mm | 1800 mm | 1820 mm | 1840 mm |

| Weight of 3 layers | 170 KG | 580 KG | 840 KG | 1140 KG | 1230 KG | 2100 KG |

The key components of a swing vibrating screen include:

Screen Frame: This is the rigid structure that supports the screen mesh. It is typically made of steel and can be designed in various shapes depending on the application.

Screen Mesh: This is the surface that separates the particles. The mesh can be made of woven wire, perforated plate, or other materials, and the size of the openings will determine the size of the particles that can pass through.

Vibration Motor: This is the motor that creates the swinging motion of the screen. The motor is usually mounted on the underside of the screen frame and is connected to an unbalanced shaft. As the shaft rotates, it creates a centrifugal force that causes the screen to swing back and forth.

Shock Absorber Springs: These springs are used to isolate the vibration of the screen from the surrounding structure. They also help to control the amplitude of the swing motion.

Transmission Device: This device transmits the vibration from the motor to the screen frame. It can be a simple shaft or a more complex mechanism, such as a gear drive.

Here's an additional component you might find in some designs:

Dust Cover: This optional cover helps to contain dust and debris generated during the screening process.

During the screening process, due to the strong adsorption, easy agglomeration, high electrostatic properties, strict requirements on accuracy, high density and light weight of various materials, it is easy to cause screen clogging, thereby significantly reducing screening efficiency. Therefore, it becomes crucial to add a screen cleaning device to the equipment. Combining many years of screening manufacturing experience, we have developed a variety of screen cleaning devices based on the needs of different materials.

Ball Cleaning System: Small balls are placed in a separate chamber and vibrate against the screen, dislodging any stuck particles.

Kleener System: Small scraper blades move across the underside of the screen, scraping away any buildup.

Brush System: Rotating brushes sweep across the screen surface, removing any particles that might clog the mesh.

Ultrasonic System (less common): High-frequency sound waves vibrate the mesh, dislodging particles without physical contact.

| Our swing vibrating screen has been widely used in: | |

| Particles: | Oat kernel 14 meshes, cassia seeds 16 meshes, corn grits 16 meshes, rice 12-14 meshes, black beans 5 meshes, red beans 5 meshes, soybeans 6 meshes, barley 8 meshes mung beans 10 meshes, buckwheat 12 meshes, black rice 14 meshes, brown rice 14 meshes Mesh, Sesame 24 mesh, Millet 24 mesh |

| Powder type: | Traditional Chinese medicine powder is generally 60 mesh, coarse 40 mesh, oral 60-80 mesh, fine Chinese medicine mask 100-120 mesh, fried chicken wrapping powder 10-30 mesh, corn flour 30 mesh, almond powder 30-40 mesh, flour 50-60 Mesh, intestine powder 60 mesh, whole grains 30-40 mesh, Panax notoginseng powder 80-100 mesh, pearl powder 120-150 mesh, pine pollen 80-120 mesh, coffee powder 100-120 mesh |

| Liquid type: | Filter soybean milk, honey 60-120 mesh, filter medicine residue, soup residue, tea water 80-150 mesh |

| Other kind: | Zanthoxylum bungeanum 6 mesh, insect excrement sieve 30 mesh, cat litter 30-40 mesh, butterfly surface 50 mesh, pepper seed 8-10 mesh, sand painting 80-120 mesh, edible oil, mechanical oil residue 150-200 mesh, Tenebrio molitor Egg sieve 12 mesh |

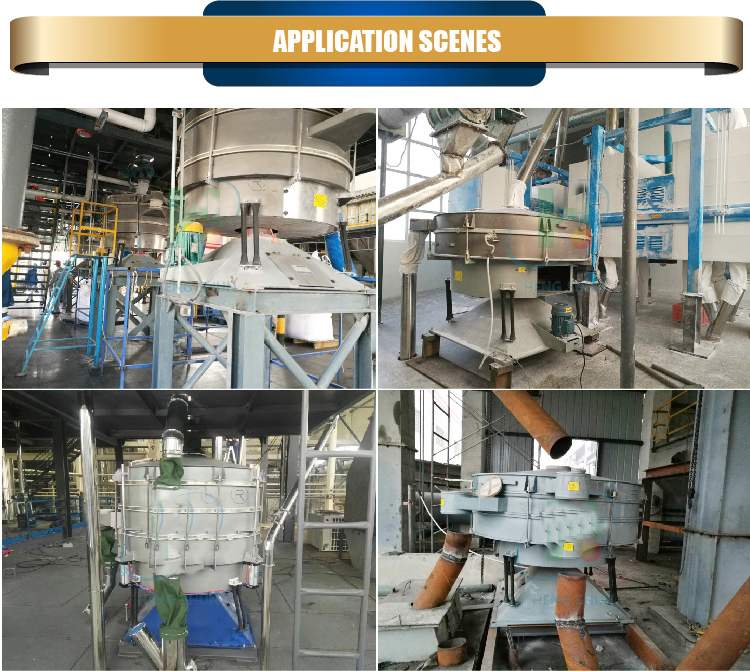

Swing vibrating screen for controlled sieving, fractionation and dedusting of dry, powdered and granular products. Especially suitable for high feed rates and multilayer separation of fine, light products that are difficult to screen. Suitable for chemical, food and fragrance, plastic, mining, pharmaceutical, wood and plywood, metallurgy, rubber, feed, fertilizer, sugar, salt, recycling industries.

Xinxiang Dahan is a professional manufacturer of vibrating screen equipment, including swing vibrating screen. We are committed to providing high-quality, reliable vibrating screen products and have rich manufacturing experience and technical strength. Whether it is a round or square swing vibrating screen, we can customize it according to customer needs to meet the screening needs of various industries. Our products have the advantages of efficient screening, durability and reliability, and easy maintenance, providing excellent performance and results for your screening process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.