Z-type bucket elevator for conveying puffed food is a continuous conveying equipment specially used for puffed food production lines. It lifts the material from low to high through the hopper through the Z-shaped conveying path, and realizes the horizontal-vertical-horizontal path change during the conveying process, lifting the puffed food from low to high. It is widely used in the transportation of light materials such as puffed food, snacks, and grains.

Z-type bucket elevator for conveying puffed food is mainly composed of a shell, a traction part (conveyor chain), a hopper, a driving wheel, a redirecting wheel, a tensioning device, a guide device, a feeding port, and a discharge port.

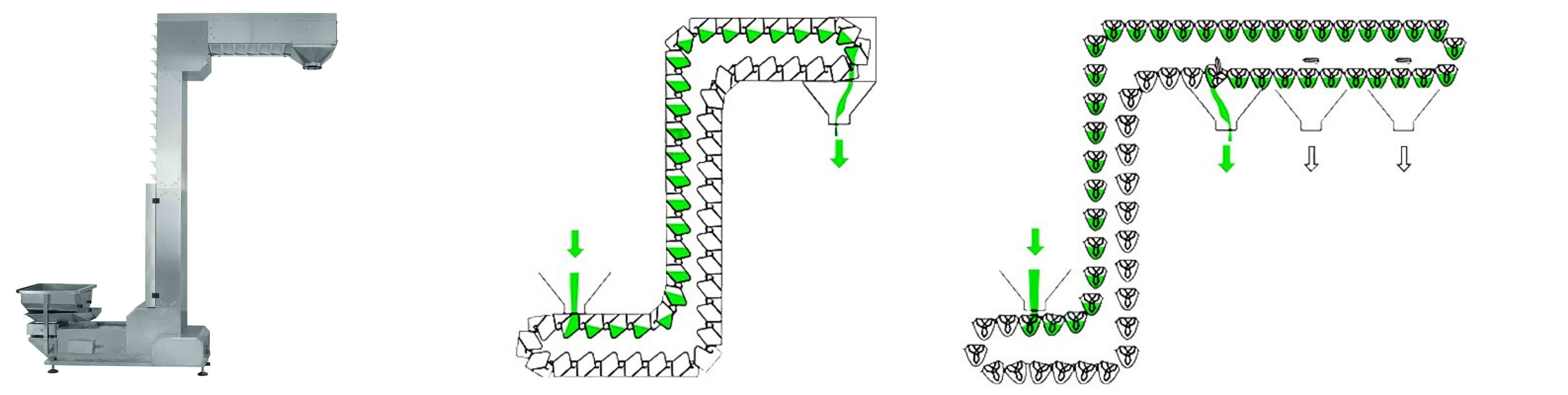

① After starting, the hopper scoops the material from the storage bin, lifts it to the top with the conveyor chain, and flips over after bypassing the top wheel to pour the material into the receiving tank.

② By changing the position of the discharge, multi-point discharge can be achieved.

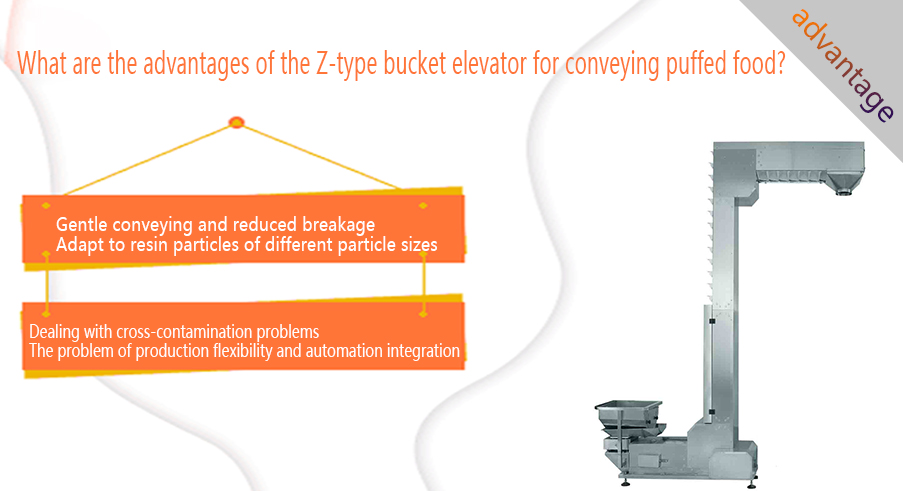

1. Gentle conveying and reduced breakage: The hopper of Z-type bucket elevator for conveying puffed food adopts overlapping or dense design. The material is always in the hopper during the conveying process, avoiding possible extrusion or falling in the traditional conveying method.

2. Adapt to resin particles of different particle sizes: Z-type bucket elevator for conveying puffed food can adopt different suction and conveying methods according to the resin particles of different particle sizes, such as pneumatic conveying, vacuum conveying, etc., to ensure the effective treatment of different particles

3. Dealing with cross-contamination problems: When producing puffed foods with multiple flavors, the conveying equipment is prone to residues from the previous batch of materials, resulting in mixed flavors or cross-contamination. Z-type bucket elevator for conveying puffed food is equipped with a quick-release design, which can quickly replace or clean the hopper to reduce the risk of cross-contamination.

4. The problem of production flexibility and automation integration: Z-type bucket elevator for conveying puffed food supports single-point or multi-point unloading, can flexibly switch production lines, and can be used in conjunction with automatic weighing machines, packaging machines, and filling machines to achieve intelligent conveying.

Hopper: a container for puffed food, usually made of food-grade plastic or stainless steel.

Conveyor belt or chain: used to connect and drive the hopper, usually made of food-grade materials.

Drive device: includes motor, reducer and transmission device to provide power.

Casing: closed structure to prevent material spillage and dust pollution.

Feed port and discharge port: located at the bottom and top of the equipment respectively, used for material input and output.

|

Parameters |

Specification range |

Parameters |

Specification range |

|

Conveying capacity |

2~10 m³/h |

Hopper material |

Food grade PP plastic Stainless steel 304 |

|

Hopper volume |

0.5L~5L |

Lifting height |

2~6m |

|

Lifting angle |

90° |

Feeding method |

Vibration feeding Direct feeding |

|

Discharging method |

Single point 、Multi-point discharging |

Motor power |

0.75~2.2kW |

|

Structural material |

Carbon steel spraying Stainless steel 304 316L |

Power supply |

220V/380V, 50/60Hz |

|

Noise level |

≤65dB |

Conveying speed |

0.1~1m/s |

1. Puffed snack production line: Z-type bucket elevator for conveying puffed food is used to transport potato chips, shrimp strips, popcorn, puffed corn cobs, etc. from the bottom feeder to the packaging machine or sorting machine to ensure continuous operation of the production line.

2. Weighing and packaging system: Z-type bucket elevator for conveying puffed food is used with a multi-head combination scale and an automatic packaging machine to achieve quantitative packaging, ensure accurate feeding, and reduce waste.

3. Material transportation in food processing plants: In food processing workshops, Z-type bucket elevator for conveying puffed food is used to transport raw materials between multi-layer equipment to improve the degree of automation and reduce manual handling.

4. Puffed pet food production: Z-type bucket elevator for conveying puffed food is suitable for conveying granular pet foods such as puffed cat food and dog food to ensure uniform distribution of materials and damage-free transportation.

Z-type bucket elevators for conveying puffed food are widely used in the puffed food industry. They can transport food efficiently, non-destructively and safely, and improve the level of production automation. If customized equipment is required (such as special materials, lifting height, multi-point unloading, etc.), we can provide detailed process requirements to recommend the best solution!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.