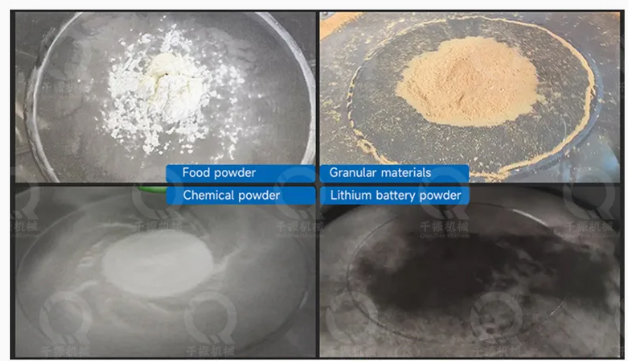

Sieving talc powder by rotary vibrating sieve is a common practice in industries such as cosmetics, pharmaceuticals and food processing. Known for its soft and lubricating properties, talc powder requires precise sieving to ensure product quality and consistency. Precise sieving is required to ensure consistent particle size and purity. A rotary vibrating sieve is an advanced sieving solution.

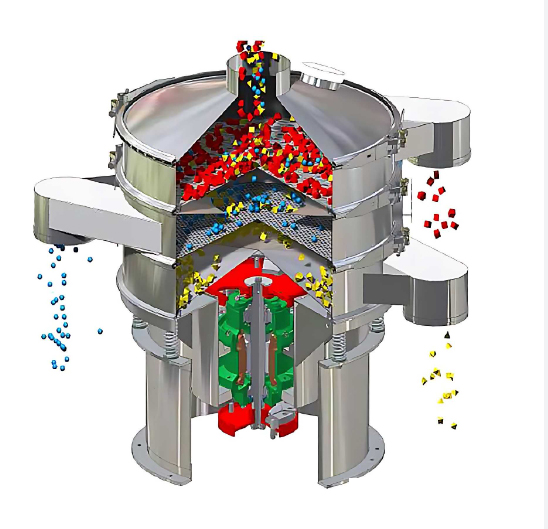

Sieving talc powder by rotary vibrating sieve operates by combining rotary motion and vertical vibration generated by an eccentric motor or vibrator. This dual motion mechanism ensures that the talc powder is evenly distributed on the sieve surface, preventing clogging and increasing sieving efficiency. Key components include:

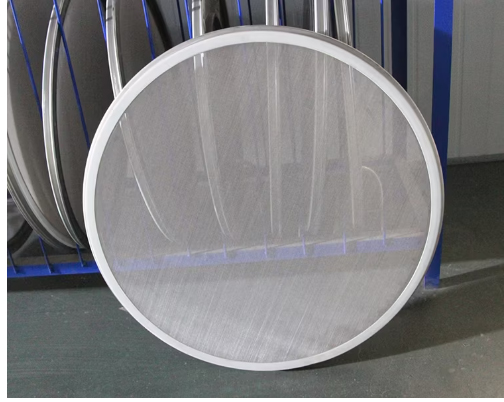

Sieve: Available in a variety of mesh sizes to achieve the desired particle size separation.

Vibrating motor: Provides the necessary vibration force to move the powder through the sieve.

Spring: Isolates the vibrating motion from the machine base, ensuring stability and reducing noise.

Sieving chamber: Designed to contain the powder and facilitate smooth sieving.

As talc is fed into the sieve, the rotational and vibrating motions work together to separate fine particles from oversized or undersized material. Fines pass through the screen, while larger particles are discharged through a separate outlet.

High sieving efficiency: The dual motion mechanism ensures thorough sieving, even of fine talc, resulting in a high yield of precisely sized particles.

Precise particle size control: With customizable mesh sizes, rotary vibrating sieves enable precise particle size distribution, which is critical for applications such as cosmetics and pharmaceuticals.

Anti-clogging design: The combination of rotation and vibrating motion prevents mesh clogging, ensuring continuous operation and reducing downtime.

Gentle handling: The gentle sieving process maintains the integrity of the talc particles, preventing breakage or damage.

Sieving talc powder by rotary vibrating sieve is a critical step in the production process to ensure product quality, consistency and purity. By adopting this efficient and versatile screening technology, manufacturers can achieve precise particle size distribution, improve production efficiency, and meet the stringent quality standards required by industries where talc is a key ingredient. Investing in a high-quality rotary vibrating screen specifically for talc screening can improve overall process efficiency and product quality in a variety of industrial applications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.