Vibrating sieve for millet removal is mainly used to remove impurities in millet, such as pebbles, dust, weed seeds, etc. In general, a multi-stage screening combination can be used to gradually improve the purity of millet. For example, a 10-mesh sieve is used for primary screening, and then a 30 mesh and 60 mesh sieve is used for fine screening. It is often used in grain processing, food processing plants or seed processing and other occasions.

Vibrating Sieve for millet is widely used in millet processing industry, mainly used in the following links:

1. Millet de-stone: remove stones and other impurities from millet.

2. Millet grading: grade millet according to particle size to meet the needs of different products.

3. Pretreatment before millet processing: provide qualified raw materials for subsequent processing steps.

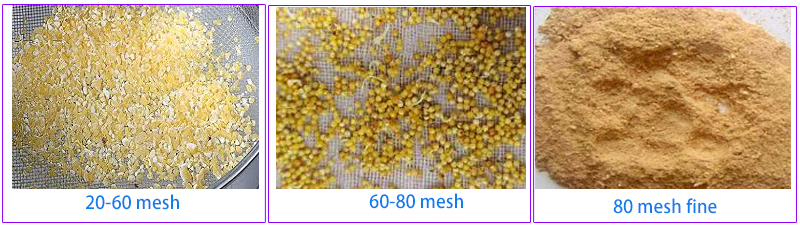

For the screening of millet particles, the common mesh number recommendation usually depends on the required particle size and product quality requirements. The following are some common mesh number recommendations, but the actual selection should be adjusted according to specific circumstances and needs:

Coarse screening (primary screening): generally use 20 mesh to 60 mesh screens to remove larger impurities and particles.

Medium screening (intermediate screening): 60 mesh to 80 mesh screens can be selected for further screening of particles to ensure the uniformity and quality of the product.

Fine screening (fine screening): It is recommended to use a screen with a mesh size of 80 or above to ensure the consistency and quality of the particle size of the final product.

Different types of vibrating sieves can be used to screen millet. Choose the appropriate vibrating sieve according to the particle size, production needs and quality requirements. Here are some common types:

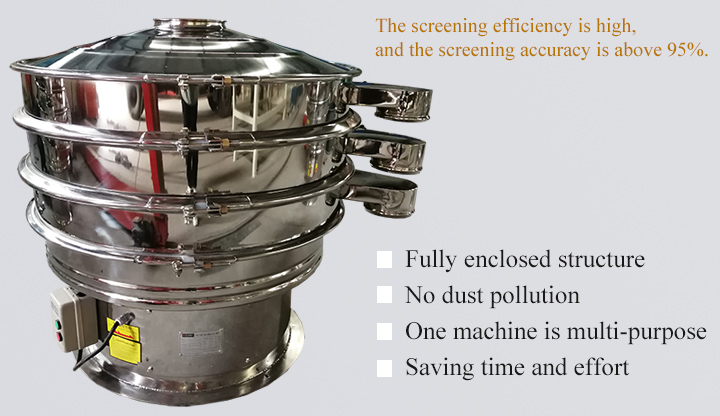

1. Circular vibrating sieve

Suitable for multi-layer screening, can be used for fine screening of millet, grading millet, and obtaining millet of different particle sizes. Mesh range: 10-100 mesh or more.

2. Ultrasonic vibrating sieve

Suitable for millet screening of sticky and fine-grained materials, can be used to process millet with high moisture content or high viscosity, and remove fine dust or impurities. Mesh range: 40-200 mesh or more.

3. Linear vibrating sieve

Mainly used for coarse screening of millet, removing larger impurities such as stones, weeds, etc., suitable for screening millet in large quantities.

Mesh range: generally between 2-10 mesh.

Generally speaking, for coarse screening of millet, you can choose a linear vibrating sieve; for fine screening and ultra-fine screening of millet, you can choose a circular vibrating sieve or an ultrasonic vibrating sieve. When choosing the mesh size of the sieve, choose according to actual needs.

Millet's impurity removal process is inseparable from the vibrating sieve. Generally, it enters the center screen surface of the two-layer vibrating sieve through manual feeding or automatic feeding device. Since the screen machine is running, the two upper and lower weights and the counterweight in the base produce a Circulating from the center and with the movement trajectory of the upper and lower amplitudes to the edge, the millet jumps along the movement trajectory on the screen surface and gradually rotates to the discharge port, falling into the barrel or the material receiving device. According to the particle size of rice flour, a shorter or longer motion trajectory can be selected to improve the discharge speed or screening accuracy.

Vibrating sieve for millet removal has the following advantages:

1. Efficient impurity removal: Vibrating sieve can quickly and effectively separate millet particles and impurities through the vibration of the sieve, thereby improving the efficiency of impurity removal.

2. Fine screening: Fine screening can be achieved according to the selection of sieves with different mesh sizes to ensure the removal of fine impurities and improve product quality.

3. Protect the integrity of particles: The vibration and screening of millet particles by vibrating sieve during the impurity removal process is relatively gentle, which helps to protect the integrity and particle size of millet particles.

4. Strong durability: Made of wear-resistant and corrosion-resistant stainless steel, it extends the service life of the equipment.

5. Easy to clean: The surface is smooth, easy to clean, and meets food hygiene standards.

6. Save space: The vibrating sieve for millet occupies a relatively small area, saving plant space.

Dahan Machinery offers a variety of separators and filters. Since we are a manufacturer of vibrating screens and self-cleaning filters, we have also gained a lot of trust in supporting the processing industry over the past 13 years. We offer separators ranging from circular to linear designs and from vacuum separation to centrifugal separators, all of which have different applications.

We encourage our customers to get help from one of our screening experts and try your product through our free trial facility. Our experts can advise you to choose from various designs of separators, accessories used and sizes according to your requirements. Let's not waste time, feel free to contact us.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.