As a kind of efficient material conveying equipment, screw conveyor is widely used in the industry. Common screw conveyors mainly fall into the following categories:

Horizontal screw conveyors generally use a "U"-shaped trough. When the conveyor is working, the material enters the inlet from one end along the displacement direction, and is discharged from the middle or the outlet at the other end. Its characteristic is that it is suitable for the transportation of large quantities of materials or mixed materials, and the horizontal screw conveyor is low-speed and short-distance transportation.

The structure of the vertical screw conveyor is simple, the floor space is small, and the manufacturing cost is low. The disadvantage is that the conveying volume is small, and the conveying height generally does not exceed 8m. However, its rotation speed is much faster than other screw conveyors, and it can quickly and vertically lift general bulk solid materials.

Inclined screw conveyors are generally designed with an inclination angle between 45 degrees. If there is a special order, you can also contact the engineer to negotiate the inclination angle. It should be noted that with the increase of inclination, the gravity of the conveyor will increase, resulting in a decrease in conveying efficiency. The solution is to increase the motor power or the thickness of the pipe wall.

The material to be transported needs to be transported over a long distance. At this time, we need to increase the length of the pipeline, but this may affect the material delivery volume and delivery speed. Therefore, we designed the spiral tube conveyor. The spiral tube conveyor adopts a new type of suspended intermediate suspension bearing frame, which increases the material transportation space and reduces the long-distance transportation resistance of logistics. In addition, small diameter, high speed, and variable pitch And other designs to ensure smooth, fast and even feeding.

Our shaftless screw conveyor adopts the design of no central shaft, which increases the material conveying area and makes it easy to convey materials that are difficult to convey. The shaftless screw conveyor is suitable for conveying bulk materials with high water content, stickiness and winding .

The most widely used conveyors are often seen in mining, feed, grain and construction industries. Among them, the screw conveyor with high evaluation and common application is single screw conveyor. The main feature of the equipment is single-sided rotation, and standard steel pipes are used as transportation. The cylinder can transport materials horizontally or with a certain inclination angle. The rigidity of its whole structure is strong, which is suitable for conveying small pieces of materials, and powder and granular materials can also be transported.

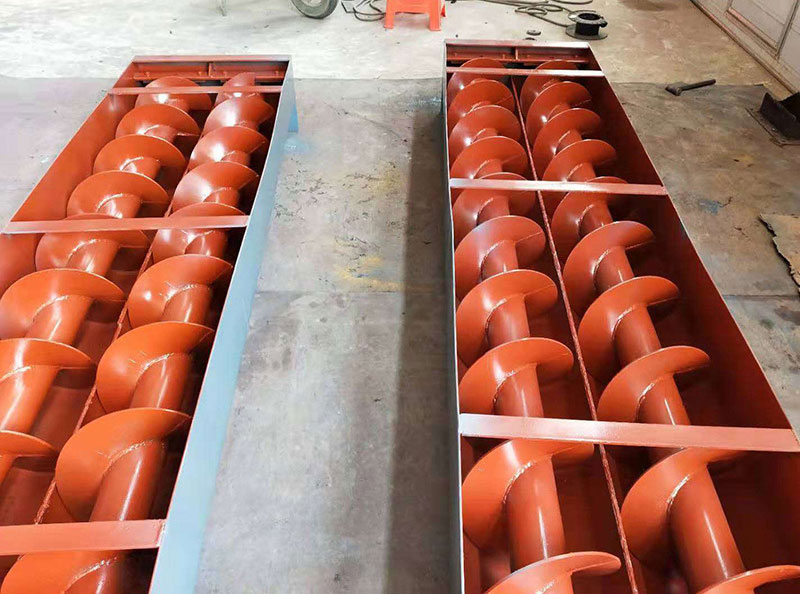

Compared with the above-mentioned single-screw conveyor, this double-screw screw conveyor is a combination of two blades. The main feature is the addition of a pre-watering section, which can stir the materials. This means that while it can be transported up and down, it can also be continuously stirred. This type of twin-screw conveyor is used to convey materials with poor fluidity, large volume or size, and needs to be stirred. It is generally used in food processing and construction processing.

Compared with the other two types of screw conveyors, the structure of the combined screw conveyor is more complicated, it is composed of two screw conveyors, there are two screw conveyors with inlet and outlet. When carrying out material transportation, if one feed port starts to convey a hopper, then the discharge port will connect with the second feed port, so generally relatively large automatic production enterprises will use this type of screw conveying machine.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.