How is the screw conveyor used in the food industry? What are the application advantages?

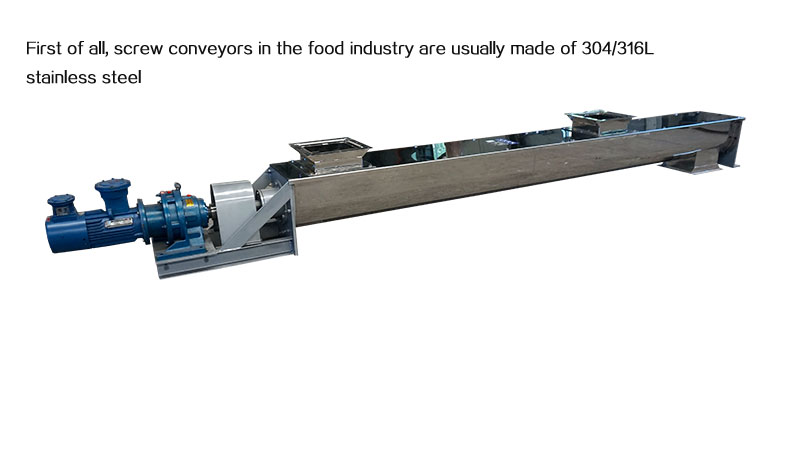

First of all, screw conveyors in the food industry are usually made of 304/316L stainless steel, which need to meet the following application standards:

1. Material safety, environmental protection and sanitation

Food screw conveyors generally use 304 and 316 stainless steel materials. The pipe walls of these two stainless steel materials have corresponding smoothness standards and need to meet hygienic requirements. After polishing, the machine can be smooth and burr-free, rust-free and hang-free Material standard.

2. The inner and outer surfaces of the pipe meet the standards

In addition to using 304 and 316 stainless steel materials for the food screw conveyor, the internal and external industries of the pipeline are also exquisitely selected. There are mainly three standards for the smoothness of the pipe surface: AP, BA, and EP. EP is an electrochemical grade that is more expensive. Generally speaking, the inner surface of the food screw conveyor is smoothed with BA, which can meet the requirements of customers for food.

3. Tight seal to reduce pollution

The food screw conveyor has good sealing performance, and can be specially designed for outlets at different angles. It is convenient for discharging and cleaning. During the conveying process, there are few phenomena such as dust flying and material leakage, which will not cause pollution or waste.

Food Screw Conveyor is usually used with mixers, screening machines, packaging machines, etc. in practical applications, and can be perfectly integrated into your food production line.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.