Concrete conveyors are essential equipment in the construction industry for efficiently transporting concrete from one location to another within a construction site. These conveyors help streamline the concrete placement process, improve productivity, and ensure a consistent flow of concrete during construction projects.

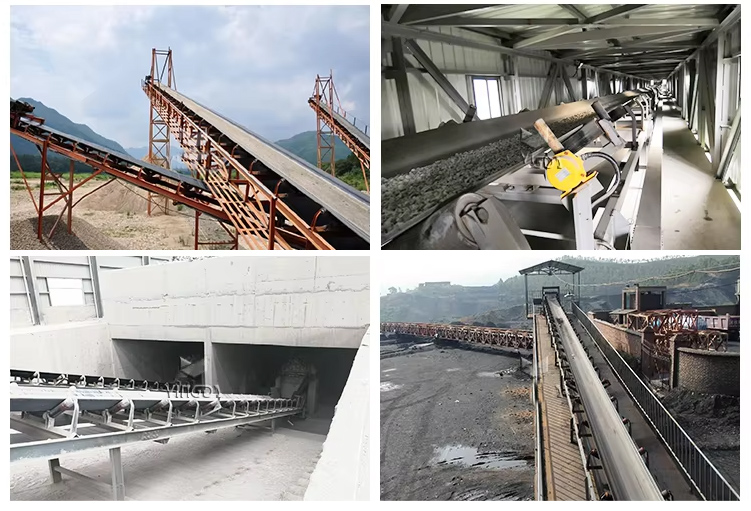

Belt conveyors consist of a continuous loop of material-carrying belts that move concrete along a specified path. They are versatile, can handle various types of concrete mixes, and are suitable for long-distance and high-capacity conveying. Belt conveyors are commonly used in large construction projects, such as high-rise buildings and infrastructure developments.

Screw conveyors use a rotating helical screw blade to move concrete along a trough. They are compact, cost-effective, and suitable for conveying materials at a controlled rate. Screw conveyors are often used for conveying concrete in small to medium-sized construction projects and batching plants.

Roller conveyors consist of rollers mounted on a frame to transport concrete by gravity or manual pushing. They are simple, easy to use, and suitable for short-distance conveying of concrete. Roller conveyors are commonly used in smaller construction sites, precast concrete plants, and material handling applications.

Telebelt conveyors feature a telescopic conveyor belt mounted on a truck or trailer for versatile and precise concrete placement. They can reach long distances, high elevations, and have the ability to convey concrete around obstacles. Telebelt conveyors are ideal for placing concrete in challenging locations, such as tall structures, tunnels, and hard-to-reach areas.

Pneumatic conveyors use air pressure to transport concrete through a pipeline system. They are efficient, dust-free, and suitable for conveying concrete over long distances and in enclosed spaces. Pneumatic conveyors are commonly used in concrete batching plants, cement silos, and construction sites where traditional conveyors may not be feasible.

Bucket conveyors use buckets attached to a chain or belt to transport concrete vertically or horizontally. They are versatile, can handle various types of materials, and are suitable for both vertical and horizontal conveying. Bucket conveyors are used in concrete mixing plants, ready-mix concrete facilities, and construction sites requiring vertical concrete placement.

By choosing the right type of conveyor, construction companies can ensure efficient concrete placement, improved workflow, and timely project completion.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.