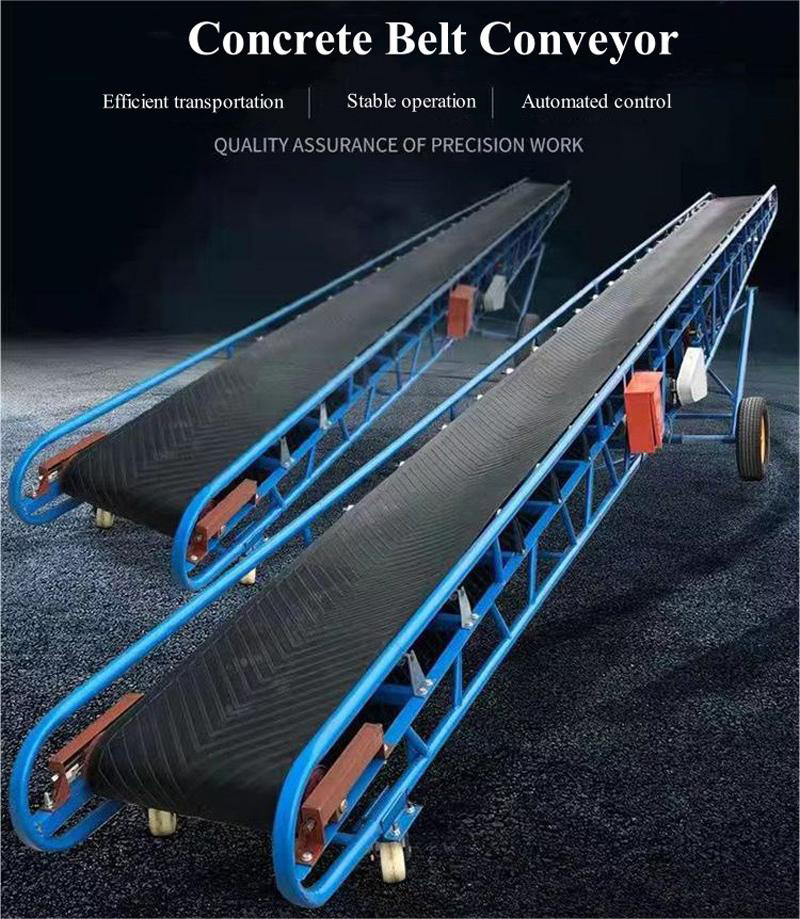

Continuous transportation of materials is achieved by driving the conveyor belt, which is widely used in construction sites, concrete mixing stations and other places.

![]()

![]()

Price::$599.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Slope Angle: 0-30

Belt width: 500/650/800/1000mm

Conveying length: Max.25 meters

Conveying capacity: 50-550m³/h

Conveying speed: 0.8-2.0 m/s

Lifting Height: adjustable

Application: Concrete belt conveyors are widely used in construction sites, concrete mixing stations and other scenarios to transport concrete, mortar, gravel, sand and other building materials.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Concrete belt conveyors are a specific type of conveyor system used in the construction industry for the efficient transport of concrete or similar materials. It is designed to handle the heavy loads and abrasive nature of concrete, ensuring a continuous and controlled flow from one location to another.

The main purpose of concrete belt conveyors is to simplify the concrete handling process in construction projects. It eliminates the need for manual labor and manual transport of concrete, increasing efficiency and productivity.

Concrete belt conveyors can be divided into three types according to different application scenarios and needs:

| Types | Fixed concrete belt conveyors | Movable concrete belt conveyor | Telescopic concrete belt conveyor |

| Description | It is usually used for concrete transportation at a fixed position. It is installed at a fixed position and the transportation path is relatively fixed. | It has the function of moving and can be moved and the conveying path can be adjusted as needed. The walking device can be wheeled or crawler-type. | It has a telescopic function, and the conveying distance can be adjusted as needed, and it can be applied to various complex terrains and construction environments. |

| Feature | Large conveying volume and high efficiency; relatively large floor space and poor flexibility. | High flexibility, small footprint, suitable for concrete transportation at different distances; the price is relatively high. | It is retractable and can adjust the conveying distance as needed; it is highly adaptable and flexible and can adjust the conveying path as needed. |

| Application Scenario | Concrete delivery from mixing station to unloading point; Concrete delivery at fixed position in construction site; Concrete delivery for large engineering projects. | Concrete conveying at different locations in the construction site; Concrete conveying that requires frequent adjustment of the conveying path. | Concrete delivery in high-rise buildings; Concrete delivery in narrow spaces; Concrete delivery in areas with complex terrain. |

Concrete belt conveyors are commonly used in the following applications:

1. Concrete mixing plants: They transport concrete from the mixing plant to the construction site directly or through intermediate storage facilities.

2. Concrete pouring and pouring: They transport the concrete from the mixing station to the specific location that needs to be poured or poured, such as formwork, mold or building formwork.

3. Concrete mixer trucks: They receive concrete from transport mixers and transfer it to the desired location on the construction site, thus enabling continuous and efficient concrete supply.

4. Construction sites: Concrete belt conveyors are often used to transport concrete from the mixing station to the construction site.

5. Concrete belt conveyors are also commonly used in large-scale engineering projects, such as bridge construction, tunnel construction, etc., to transport concrete and other construction materials.

The working principle of the concrete belt conveyor is to drive the conveyor belt through the driving device to transport concrete and other construction materials from one location to another. During the working process, concrete is placed on the conveyor belt, which is supported by rollers. The conveyor belt is driven by the transmission device to continuously transport the concrete along the set transmission line. The running speed and direction of the conveyor belt can be adjusted as needed to meet the transportation requirements in different scenarios.

Efficient transportation

They can transport concrete continuously and in a controlled manner, reducing the time and effort required for manual handling.

Flexibility

The length and angle of the concrete belt conveyor can be adjusted to suit different job site conditions and project requirements.

Increased productivity

By automating the concrete transportation process, belt conveyors help increase productivity and reduce labor costs.

Reduce material waste and spillage

Compared to manual handling methods, concrete belt conveyors minimize material waste and spillage, ensuring more efficient use of concrete.

Different types of cement belt conveyor belts play a key role in the cement production process. You can choose the right type of conveyor belt according to specific needs and working environment.

Wear-resistant conveyor belt: suitable for scenes that need to withstand long-term wear in cement production, and can maintain a long service life.

Skirt belt: Skirt belt is a design with rubber skirts on both sides of the conveyor belt, which can effectively prevent material overflow and is suitable for cement conveying processes that need to avoid material overflow.

Polyester belt: It has good tensile strength and wear resistance, and is suitable for cement conveying machinery that needs to withstand high tension and large pulling force.

| Model | Belt Width (mm) | Lenth(m) | Belt Speed (m/s) | Lifting Height | Slope Angle | Capacity (m³/h) |

| DY-500 | 500 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 50-140 |

| DY-650 | 650 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 100-250 |

| DY-800 | 800 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 170-350 |

| DY-1000 | 1000 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 270-550 |

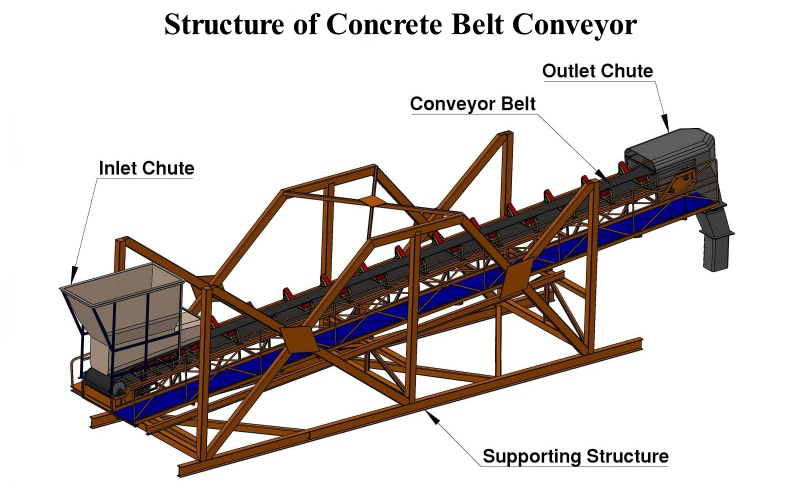

Concrete belt conveyor is mainly composed of conveyor belt, driving device, roller, tension device, support device, transmission device, protection device, etc.

The conveyor belt is responsible for transporting construction materials such as concrete.

The driving device provides power to drive the conveyor belt to run.

The rollers support the conveyor belt.

The tension device is used to adjust the tension of the conveyor belt.

The support device supports the conveyor belt structure.

The transmission device transmits power to the conveyor belt. , the protection device ensures the safe operation of the equipment.

Belt Design: Concrete belt conveyors typically use heavy-duty, reinforced rubber belts that are abrasion-resistant and have high tensile strength. These belts are designed to withstand the weight and abrasive nature of concrete without stretching or tearing.

Belt Width and Capacity: Various belt widths are available to suit different project requirements. The width of the belt determines the capacity of the conveyor to transport concrete per unit time.

Belt Support Structure: Equipped with a strong support structure, usually made of steel, to provide stability and ensure that the belt remains aligned and properly tensioned during operation. The structure may include rollers or idlers to support the belt and guide it along the desired path.

Drive system: The hybrid is powered by an electric motor or engine, providing the necessary torque to move the belt and transport the concrete. Drive systems may include pulleys, gearboxes, and other components to control the speed and direction of the belt.

Safety Features: Concrete belt conveyors have safety features that protect workers and prevent accidents. These may include emergency stop buttons, safety guards and sensors to detect belt misalignment or excessive tension. When operating a concrete belt conveyor, it is important to follow safety guidelines and regulations.

Xinxiang Dahan is a well-known concrete equipment manufacturer, focusing on the research and development, production and sales of concrete equipment. The concrete belt conveyors it produces are known for their high quality and high efficiency. The products have advanced design, stable structure and easy operation, and are widely used in construction sites, concrete mixing plants and other fields. The manufacturer focuses on technological innovation and quality control, has a complete after-sales service system, and is deeply trusted by customers. Its products are not only well received in the domestic market, but also exported to many countries and regions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.