The electric sieve shaker adopts electromagnetic drive, three-dimensional movement, and can sieve to 20 microns (635 mesh). This article will introduce the electric sieve shaker in detail for you.

The electric sieve shaker uses the electromagnetic vibrator as the vibration source, adopts high-frequency up and down vibration, and the vibration frequency can reach 3,000 times/min. The material is thrown from the screen without sticking to the screen, and is sieved to 20 microns (635 mesh). Solved the problem of ultrafine powder dry sieving.

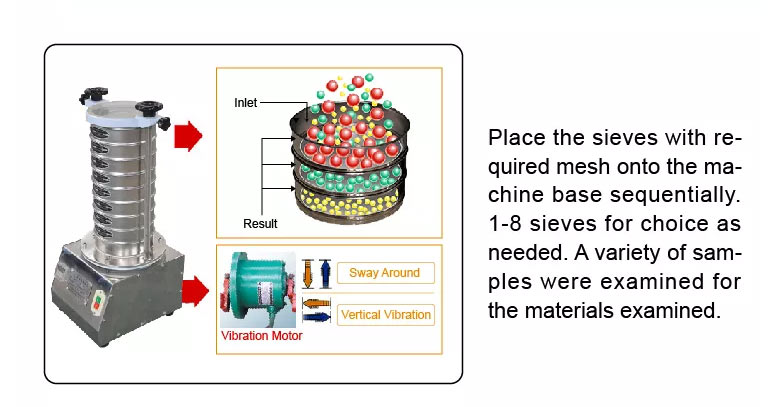

The electromagnetic test uses an electromagnetic vibrator as the vibration source. The vibration of the electromagnetic vibrator drives the low-position vibration of the sieve machine, and then passes through the base to a set of standard test sieves arranged from coarse to fine on the base. At the same time, the vibrating motor (or reciprocating The mechanism) selects and screens the materials, and the materials vibrate on the screen surface of the standard inspection sieve, so that the material particles smaller than the pore size of the screen are sieved into the lower inspection sieve, and the layers are screened. Only each layer of the test sieve has the same Particle size to achieve separation of different particle sizes.

1. Using electromagnetic drive + three-dimensional movement, dry and wet sieving, can quickly separate particles and measure particle size distribution.

2. Electromagnetic drive, the vibration frequency is 1440-3000r/min, and it can measure samples weighing up to 2kg in the range of 120mm to 20μm.

3. The sieve machine can be equipped with 8 layers of test sieves (including the bottom of the sieve), which can accurately separate 2-7 particle size segments from a granular material at the same time.

4. 0-99 minute timer, which can automatically shut down at a fixed time to ensure the repeatability of the experiment and the reliability of the data.

The above is the introduction of the electric sieve shaker. The electric sieve shaker is used in the laboratory to analyze the particle size of various materials in the chemical industry, food and other industries. The dry sieve can be sieved to 20 microns (625 mesh), and the negative pressure device can be installed to sieve to 5 microns. , to solve the screening problem of ultrafine powder.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.