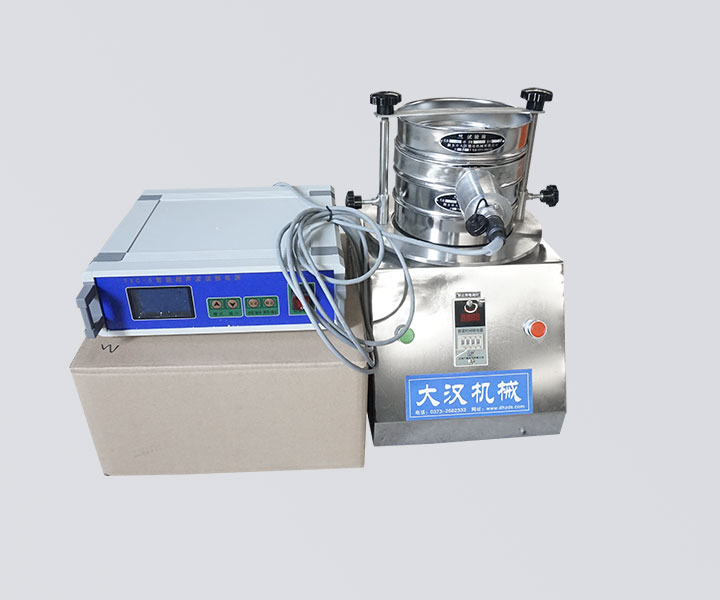

Electric sieve shaker

Electric sieve shaker Electric soil sieve shaker

Electric soil sieve shaker Electric flour sieve shaker

Electric flour sieve shaker 200mm electric sieve shaker

200mm electric sieve shaker 300mm electric sieve shaker

300mm electric sieve shaker

Detection of particle size distribution or impurity content of granular materials, as well as the content of solid materials in liquids

![]()

![]()

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

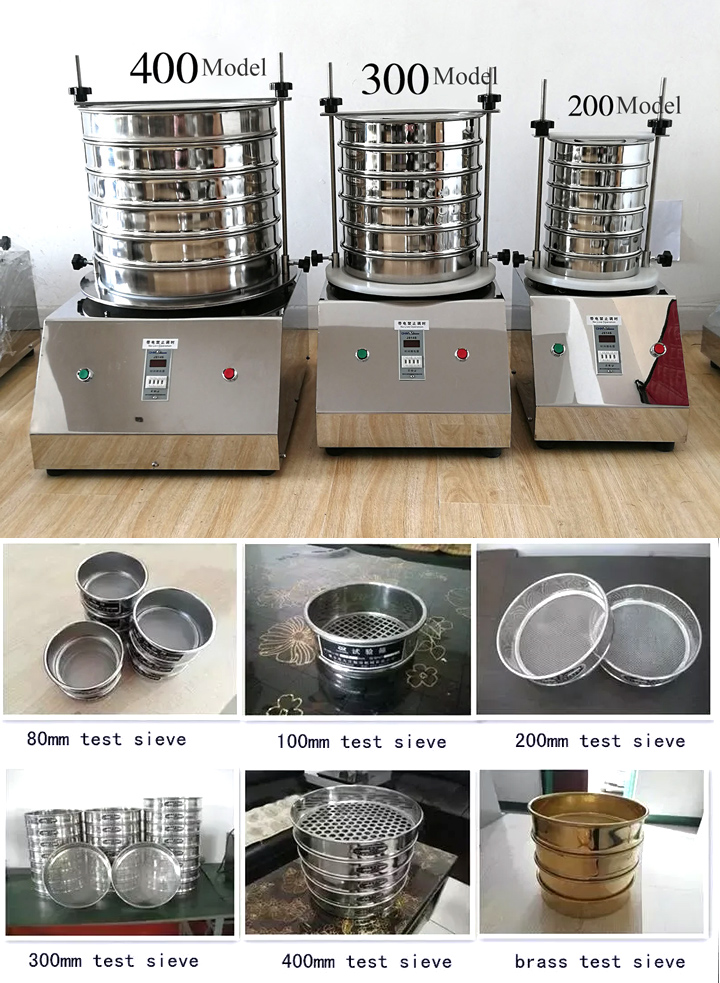

Sieve diameter:75mm、100mm、200mm、300mm、400mm、500mm

Range:20µm-125mm

Mesh:20-800 Frequency:1440-3000r/min

Time setting:99 minutes Weight:36 kg

Dimension(L*W*H):Standard, 360*300*(300+N*56)

Layer(s):1~8 Layers Voltage:220V/380V

International standard:ISO3310-1:1990 R20/3, R20, R40/3 series

Commitment:

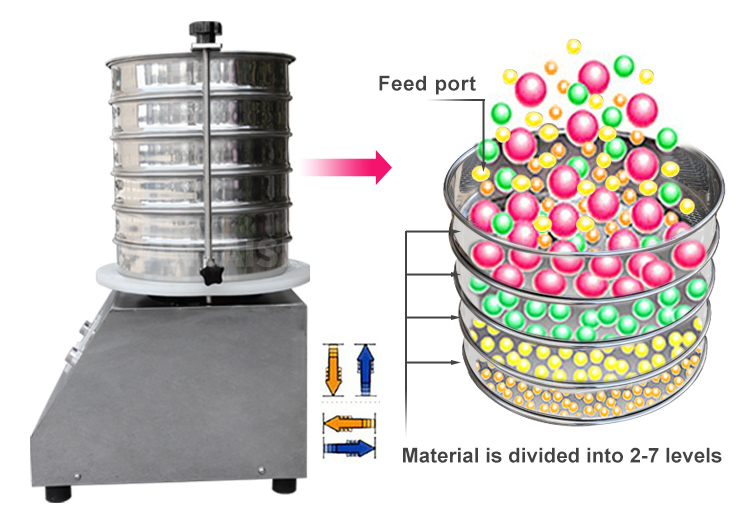

Electric sieve shaker adopts electromagnetic vibrator as the vibration source, the vibration frequency is up to 3000 times/min, and the sieve surface adopts high-frequency vibration up and down, so that the product can be thrown out from the mesh, and it is not easy to stick to the mesh, which improves the sieving of fine powder or fine particles. Separation efficiency, can sieve to 20 microns (635 mesh), add negative pressure device, can sieve to 5 microns, solve the problem of ultrafine powder dry sieving. The height of the sieve machine can hold 8 layers of sieves (including the bottom of the sieve), which can precisely separate a kind of granular material into 2-7 particle size segments at the same time.

Electromagnetic drive

The electromagnetic vibrator is used as the vibration source, and the vibration frequency can reach 3000 times/min. Because the screen surface can vibrate up and down at high frequency, the product can be thrown out from the mesh, and the material is not easy to stick to the mesh, which improves the screening efficiency of fine materials.

Accuracy and efficiency

The dry sieve can sieve to 20 microns (625 mesh), and the negative pressure device can be added to sieve to 5 microns, which solves the problem of ultrafine powder dry sieving. Sift sample volumes up to 2 kg with greater than 95% accuracy.

SUS stainless steel

The screen frame, vibrating plate, and box are all made of SUS304 stainless steel with a wall thickness of 0.6mm, non-magnetic, and durable.

Multi-layer detection

The sieve machine can place 8 layers of test sieves (including the bottom of the sieve), and can precisely separate a granular material into 2-7 particle segments at the same time.

Durable

Ideal for fast quality control of incoming and outgoing product, it offers user-friendly operation and is quiet and robust.

The detection time can be freely controlled

The sieving time is controlled by a time relay, and it can automatically shut down at 0-99 minutes, the time is controllable, the test is accurate, and there is no error.

Electric sieve shaker adopts advanced electromagnetic drive technology, so that the sieved sample not only vibrates vertically, but also turns and rolls at the same time, making full use of the sieve area, achieving the best reproducible sieving result in a short time, and used for particle separation And material particle size analysis and detection, dry sieving to 5 microns; mainly used in soil research, laboratories and industrial fields, specific materials include: flour, aggregate, coal, pigment, soap, cement, powder, feed, sesame, abrasive etc.

Electric Sieve Shaker for

Electric sieve shaker for testing cement powder

The Electric sieve shaker uses an electromagnetic vibrator as the vibration source. The vibration of the electromagnetic vibrator drives the vibration of the sieve machine, and then transmits it to a set of test sieves arranged from coarse to fine through the base. (or reciprocating mechanism) to spread the material, and the material is vibrated during the test, so that the particles smaller than the mesh of the sieve are screened into the lower sieve, so that only the same particle size is left in each layer of sieve, and finally the different particle size is completed.

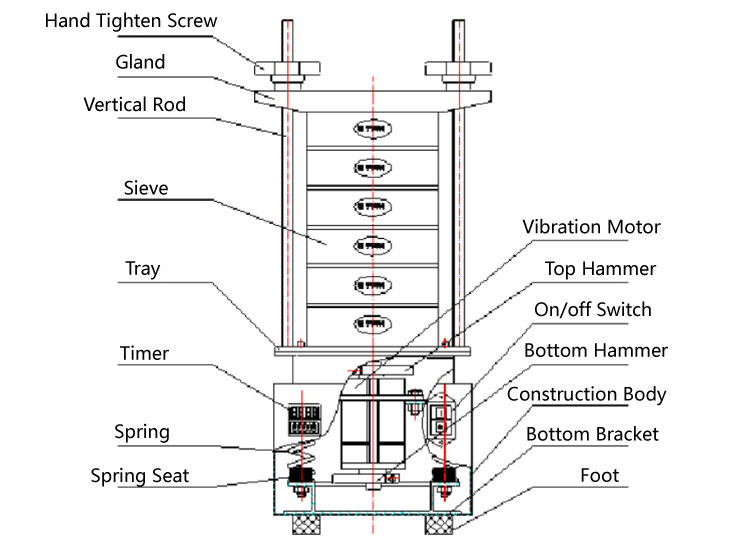

Electric sieve shaker is composed of handle, pressure plate, sieve cover, sieve frame, sieve bottom, tray, equidistant adjustment rod, time relay, vibration motor and so on.

1. Voltage and frequency: Single phase: 220V/110V, 50/60HZ, Three phase: 220V/380V/415V, 50/60HZ

2. Source: one set of vertical vibration motor

3. Diameter: 100mm、200mm、300mm

4. Includes: main unit, top cover (pan), catchers (collector) and sieves with different mesh.

5. Materials: machine is made of common steel. Top cover, catcher and sieve are SUS304

Screen: The screen is the more technical part of the electric sieve. The most common type of mesh is stainless steel woven wire mesh with openings ranging from 5 inches (125 mm) to 635 mesh (20 microns).

Screen Frame: Frames are circular metal rings that hold the mesh in place. Standard frame sizes in the U.S. are 3 inches, 8 inches, and 12 inches. Internationally, 100mm, 200mm and 300mm are standard sizes. The screen frame can be made of stainless steel or brass.

Skirt: The main function of the skirt is to allow the sieves to be stacked without tipping over.

Digital Panel: See exactly what your machine is doing.

Timer: The timing range is 0-99 minutes, and the screening time can be freely controlled.

| NO | Name | Unit | Parameter |

| 1 | Sieve diameter | mm | Φ200 |

| 2 | The quantity of layer | s | 1-7 |

| 3 | Number of revolution | Timed/min | 290±6 |

| 4 | tapping | Timed/min | 1-4 |

| 5 | Tapping height | KN | 38±6 |

| 6 | Levelness of the base | mm/min | ≤0.6 |

| 7 | Motor powder | KW | 0.37 |

| 8 | Powder supply | V | 380,220 |

| 9 | Outside dimension | LWH | 433*432*785 |

| 10 | Rotation distance | mm | 25 |

How to choose Electric Sieve Shaker?

1. Diameter: 8" (203mm) is the most commonly used, 12" (305mm), the size of the diameter is related to the test method and the vibrating screen.

2. Height: Full height 2" (51mm) is the most commonly used, half height 1" (25mm), Taylor Vibrator (RX-29-10) can accommodate 6 full-height or 13 half-height screens, customers can process samples according to Choose a full-height or half-height sieve for the total amount or the amount of samples processed at one time.

3. Material: There are three kinds of stainless steel screens (the most commonly used), copper screens, copper screens and stainless steel frames. All stainless steel screens can be selected for samples with moisture or moisture; for special requirements (such as heavy metal content) ) And dry samples can choose all-copper mesh.

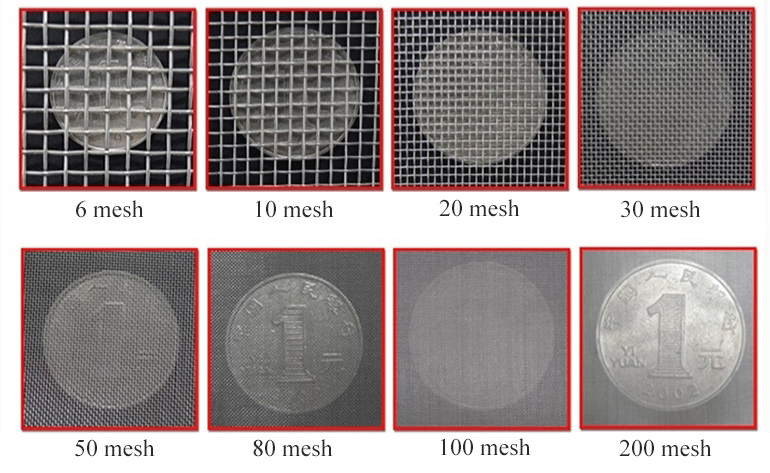

4. Aperture: The aperture is the only size of the screen, corresponding to the mesh number and the US size (NO.). However, the mesh number of some screens and the US size are not one-to-one correspondence. Only by providing the aperture of the screen can the screen be selected accurately.

The mesh number is the number of holes, which is the number of holes per square inch. The larger the mesh number, the smaller the aperture. In general, the number of mesh × aperture (micron number) = 15000.

For example, the 400-mesh sieve has a pore size of about 38 microns; the 500-mesh sieve has a pore size of about 30 microns. Due to the problem of porosity, that is, because the thickness of the wire used in weaving the net is different, the standards of different countries are also different. At present, there are three kinds of American standards, British standards and Japanese standards, among which the British and American standards are similar. , Japan is quite different. The laboratory vibrating sieve used in our country is the American standard, that is, it can be calculated by the formula given above.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

| Type | Woven Wire Sieves | Perforated Plant Sieves | Electroforming Sieves |

| It is widely used, the mesh shape is square hole, the price is cheap, the application range is wide, light and durable. | This type of screen is mostly square or round, safe and firm, and suitable for Materials with relatively high density, large impact on the screen surface and irregular shapes. | Produced by electrochemical methods, with the highest precision (can reach 1 micron), but the cost is high and will only be used in some high-precision laboratories. | |

| Diameter | 200mm, 75mm, 300mm | 200mm, 300mm | 75mm, 200mm |

| Mesh Size | 0.02mm-2.36mm | 1mm-125mm | 5μm-500μm |

| Executive Standard | GB/T6003.1-1997 (equivalent to ISO3310.1) | GB/T6003.2-1997 (equivalent to ISO3310.2) | GB/T6003.3-1999 (equivalent to ISO3310.3) |

| Comparison item | Electric Sieve Shaker | Mechanical Sieve Shaker |

| application | Powder/liquid sieving, can dry sieve 5um materials, special equipment for ultrafine powder materials that are difficult to dry sieve | For particle size separation and classification of powders/granules/suspensions |

| price | $650.00 - $1,200.00/ Sets | $20.00-$3,680.00/Set |

| Screening accuracy | 5μm | 0.025-3mm |

| model | 75mm/100mm/200mm | 75mm/100mm/200mm/300mm/400mm/500mm |

| vibration frequency | 3000 times/min | 1500 times/min |

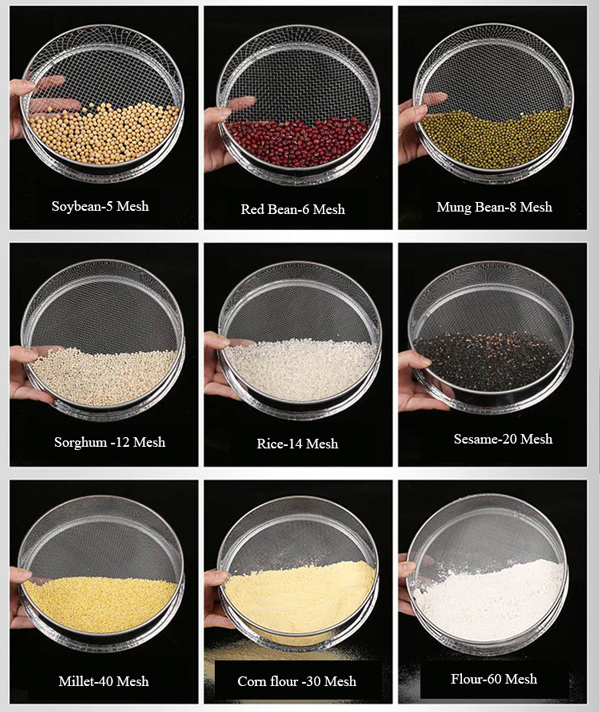

| Materials | Mesh | Materials | Mesh | Materials | Mesh |

| Worm dung | 30 mesh | Soybeans | 4-5 mesh | green beans | 10 mesh |

| Rice | 12-14 mesh | rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| flour | 50-60 mesh | Miscellaneous grains | 40-50 mesh | Sesame Millet | 22-24 mesh |

| Fried Chicken Burger Breaded | 20-30 mesh | Mung bean flour | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Traditional Chinese Medicine Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Medicine residue | 60-150 mesh | Soy milk | 80-120 mesh | honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

Electric sieve shakerS are mainly used in inspection departments such as laboratories, research institutes, item screening, screening, etc. In order to ensure the standard and accuracy of the data for testing raw materials, the following is a summary of the following points for the use of electric sieve shaker by Dahan Machinery:

1. The electric sieve shaker should be placed horizontally, confirm that the power supply meets the requirements of the nameplate, and ensure that it is grounded; the vibrating part should not be in contact with other objects; whether the bolts of each part are locked.

2. Determine the standard sieve frame to be selected according to the inspected materials and corresponding standards.

3. Stack the test sieve and the sieve frame on the vibrating plate of the test sieve machine according to the aperture from small to large, from bottom to top.

4. Put the material to be inspected into the electric sieve shaker frame at the upper end, cover the upper cover of the standard sieve, adjust the height of the adjusting rod according to the total height of the standard sieve frame, and then use the pressure plate and lock nut to feed the standard sieve frame. 5. According to the material For nature and feeding amount, set the running time on the timer, then turn on the power switch, and the standard sieve will start to work.

6. After the work stops, unscrew the lock nut, remove the pressure plate, and carefully remove the standard screen frame.

7. Cut off the power supply.

[Electric sieve shaker manufacturer] Dahan Machinery [13 years of experience], specializing in making electric sieve shaker models, reasonable price, 1 year warranty, customized quick model selection and drawing parameters.

Our electric sieve shaker production standards:

1. Screen: woven according to B6003.1-1997 standard metal wire; in line with international standards ISO3310-1: 1990 R20/3, R20, R40/3 series; material is brass H80, stainless steel SUS304. It can be electroplated, chemical The processing makes the screen surface smooth and wear-resistant, while the warp and weft threads are fixed together;

2. Screen frame: made of SUS304 (0Cr18ni9) stainless steel stretching and polishing, wall thickness 0.6mm, non-magnetic, soldering is used when connecting with the screen, this fixing method is very stable; high temperature resistance (below 300 degrees);

3. Mesh: The electric sieve shaker produced by our company adopts the method of marking according to the mesh, as long as the mesh of the same specification is the same, the mesh: square hole 0.02mm (20μ); triangle hole: 0.005mm (5μ) ); The mesh is durable and not deformed.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.