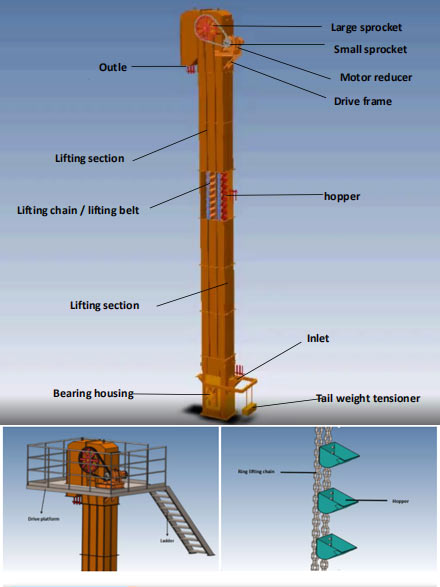

The chain bucket elevator is a kind of conveying machine, which usually adopts a series of buckets uniformly fixed on the endless drag chain to continuously lift bulk or broken materials from a low place to a high place. This article will explain the structure of the chain bucket elevator in detail.

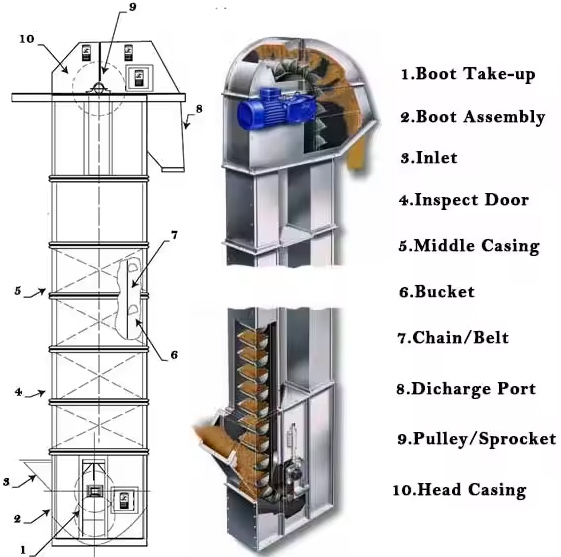

The chain bucket elevator is mainly composed of a driving device, a housing, a chain, a hopper and an inspection platform. Its main structural features are as follows:

1. Drive device

Drive shaft components, reducer, coupling, motor, etc. are assembled into one.

2. Shell

It is assembled by bending plate welding, which has the characteristics of light weight, good rigidity, and small welding deformation, which greatly improves the overall performance of the equipment. There are multiple inspection doors in the casing, which is convenient for observing the operation of the chain and the hopper, and it is also very convenient to replace the hopper and the chain.

3. Chain

Using round link chain, after proper heat treatment, it has high tensile strength and wear resistance, and has a long service life.

4. Hopper

TH type chain bucket elevator is equipped with two kinds of hoppers:

ZH type (medium-deep bucket): suitable for conveying wet, agglomerated, and difficult-to-throw materials, such as wet sand, molding sand, chemical fertilizer, alkali powder, etc.

SH type (deep bucket): suitable for conveying dry, loose and easy-to-throw materials, such as cement, gravel, coal, etc.

5. Bottom

There is a tensioning device at the bottom to ensure that the chain has sufficient pre-tightening force during the working process. At the same time, the bottom of the sprocket device is equipped with an automatic centering device to prevent the uneven tension of the sprocket from causing tilting and equipment failure.

The ring chain bucket elevator mainly relies on the hopper fixed on the chain to uninterruptedly lift the material that evenly flows into the tail inlet from the tail of the bucket elevator to the head of the bucket elevator, and then unload it from the outlet of the machine head. Lower the material to complete the entire material lifting process. It is suitable for conveying powdery, granular and small pieces of low-abrasive materials with a bulk density of less than 1.5t/m³ and easy to dig out, such as: coal, cement, gravel, sand, chemical fertilizers, etc., which is more than 30% higher than ordinary models .

Address:China,Yanjin county forest park gate to the west 1000 meters north road.