Ultrasonic sieve shaker is an ultrasonic system installed on the basis of ordinary sieve shaker. It uses ultrasonic frequency to vibrate the sieve. It is suitable for laboratory testing of high-mesh or fine powder with static electricity that is easy to agglomerate over 200 mesh. This article will introduce ultrasonic for you in detail. How the sieve shaker works.

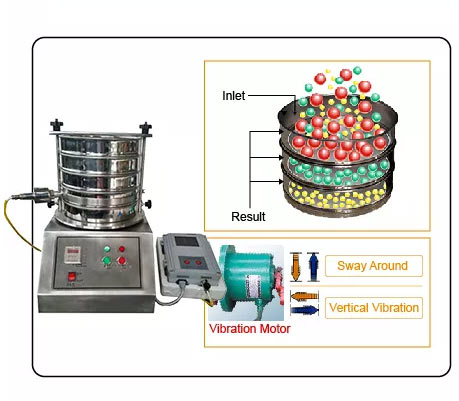

The ultrasonic sieve shaker consists of an ultrasonic vibration controller DH-300T test sieve (main machine) installed in the sieving machine. The high-frequency electrical oscillation generated by the ultrasonic vibration power supply is converted into a high-frequency sinusoidal oscillation wave by the oscillator, and the oscillator evenly distributes the oscillation wave After being sent to the screen surface, the material on the screen undergoes low-frequency three-dimensional vibration and superimposed ultrasonic vibration. The sieve frame that needs to detect the mesh size sieves the material particles smaller than the mesh of the screen surface to the lower sieve frame. The ultrafine powder stuck in the mesh is easy Through the sieve, the additional ultrasonic system can be installed on any layer of the experimental sieve, and the installation and disassembly are very convenient.

Ultrasonic sieve shaker sieves graphite powder

Ultrasonic sieve shaker sieves quartz sand

| Comparison Item | Ultrasonic Sieve Shaker | Ordinary Sieve Shaker |

| Application | Allows separation down to 20 microns (#635 mesh) | 200 mesh or more coarse mesh, more than 200 mesh is easy to block the screen |

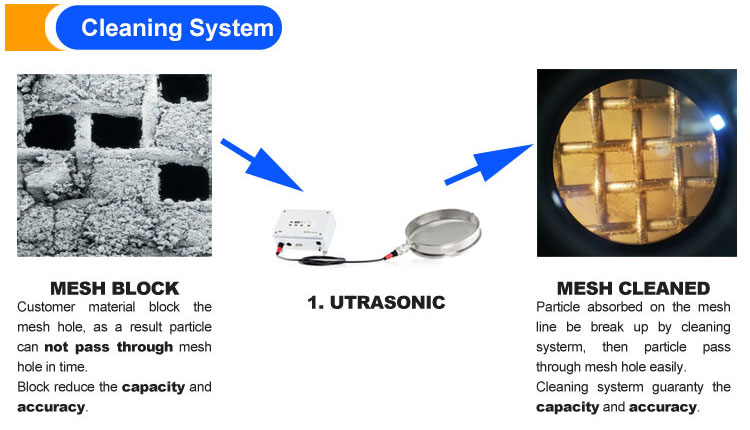

| Screening Effect | The vibration frequency is 36,000 times/second, which can quickly decompose the attachment, and the passing rate of the screen surface can be increased by 50%-400%, and the screen will not be blocked | During the process of sieving fine powder, it is easy to block the mesh, resulting in accumulation, thereby reducing the output and product quality |

| Cost of Production | Screen clogging is eliminated, product quality is consistent throughout production, and there is no downtime to clean screens, reducing the risk of downtime | The screen surface needs to be cleaned after each use. If the screen is blocked during use, it needs to be shut down for investigation, which is costly |

Materials such as metals and pharmaceutical powders can be challenging to sieve as they can easily stick to the mesh openings and cause buildup, which can reduce productivity and product quality, the Ultrasonic Deblinding System provides an automated solution for cleaning screens , to increase productivity while preventing screen clogging.

Ultrasonic sieve shaker solves the problem of sieving high-mesh products above 200 mesh or products that are easy to agglomerate and easily charged with static electricity, which are difficult for ordinary sieve shakers to sieve, such as medicine powder, gown powder, electromagnetic powder, metal powder, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.