Vibratory sifter for nut is mainly used for size grading, removing slumped seeds, dust, empty shells and other debris. It can also size and remove dry goods such as walnuts, chestnuts, jujubes, peanuts, and raisins.

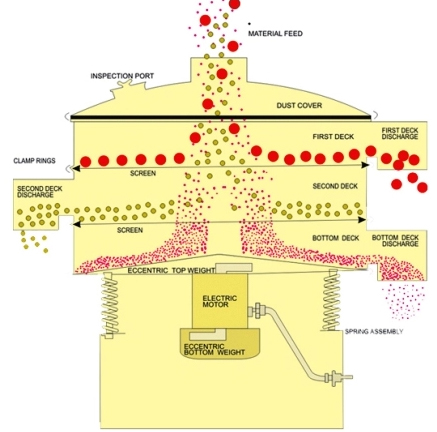

The nut is thrown forward on the sieve surface under the action of the exciting force, the seeds smaller than the sieve hole fall into the lower layer, and the seeds larger than the sieve hole move forward in a parabolic motion and fall into other silos to complete the screening operation.

1. The processing capacity of this model is 16-25 tons per hour, and the clarity can reach 98%. The screen can be replaced, large or small.

2. It is used to remove debris and dust in the nut. It is equipped with an exhaust fan, and the two-layer iron frame screen is easy to use and has a long life.

3. The machine replaces the screen according to the grain size and specific gravity requirements. The screen has a perforated plate screen and a stainless steel woven mesh. After the screen is selected, the fan can adjust the air volume according to the specific gravity of the screened material.

4. The cleaning sieve is a three-layer sieve bottom. After the first screening of the front sieve, the large impurities, fine soil and small impurities are cleaned, and then the main fan is used for air selection and cleaning before discharging. After cleaning, it is set in The small grain thrower at the front end throws long distances (with throwing grain type) to clean up the small sand contained in moldy nuts.

The motor equipped with nut is a single-phase four-stage 2.2kw motor vibration type screening, and the selected nuts meet your needs. The screen of this machine can be customized according to the needs of users.

Walnuts are poured into the hopper and then fed through vibration, which feeds them onto sieves with different sized apertures. During the vibration process, the walnuts fall into the holes corresponding to their size. At the same time, small foreign particles and shells are blown into separate compartments by the air flow.

Solve the problem of brittle nuts and high breakage rate: Nuts are brittle and easily squeezed and collided during the screening process, resulting in an increased breakage rate. Vibratory sifter for nut uses adjustable vibration frequency and amplitude to reasonably control the residence time of the material on the screen surface and reduce mechanical damage to the nuts.

Solve the problem of different sizes and shapes of nuts and difficult screening: There are many types of nuts, with different sizes and shapes, and they need to be accurately graded. Vibratory sifter for nut can be equipped with multiple layers of screens with different apertures to achieve multi-level grading and screen the nuts into different size ranges.

Deal with the problem of dust and impurities easily adhering to the surface of nuts: Dust and impurities are easily adhered to the surface of nuts during growth, harvesting and transportation. The high-frequency vibration of vibratory sifter for nut can effectively remove dust and impurities from the surface of nuts.

Deal with the problem of low efficiency and high labor intensity of nut screening: Traditional screening methods, such as manual screening, are inefficient and labor-intensive, and it is difficult to meet the needs of large-scale production. Vibratory sifter for nut can work continuously, realize automated production, and improve production efficiency.

Since its establishment 12 years ago, Dahan Machinery has a factory area of 10,000 square meters, providing screening solutions for food, medicine, chemical industry, metallurgy, building materials and other industries. Cooperative customers include Coca-Cola Company, Sundaban Industrial Complex Co., Ltd., etc. The company has ISO quality system certification and EU CE certification, and the product quality is guaranteed.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.