Vibratory sifter is suitable for screening and filtering granules, powder, mucus and other materials, and has a very wide range of applications in the industrial, ceramic, paper, metallurgical, and pharmaceutical industries.

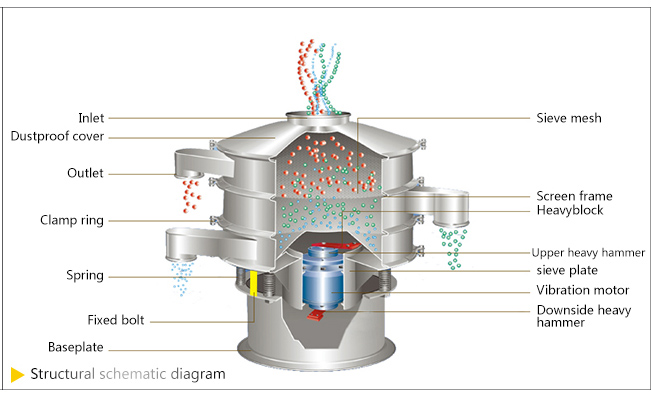

Vibratory sifter is composed of dust cover, screen frame, screen, net frame, net cleaning device, motor (vibration source), damping spring, base and other parts.

1.Dust cover

It is composed of a feed port and an oblique cone, and its lower end is connected with the screen frame to prevent the dust in the workshop from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel and plastic. Etc. 3 kinds of materials.

2.Sieve frame

It is formed by coil welding of steel plates, with bearing rings at the upper and lower ends, and flange rings in the lower part, which are used to fix the structure of the screen components.

3.Vibration motor

The vertical vibration motor is divided into four specifications of 2, 4, 6, 8, and horizontal. The vibration times are 2870, 1460, 980, 740RPM respectively. It can be designed as explosion-proof type (flammable and explosive occasions)

4.Sieve

Models are φ600, 800, 1000, 1200, 1500, 1800, etc. The materials are stainless steel, carbon steel, and plastic.

5.Cleaning device

Clean the blocked materials in the screen mesh to increase the output. It is made of silicone and rubber. You can also choose an ultrasonic cleaning device (635 mesh fine powder with static electricity).

6.Damping spring

There are 12-20 vibration isolation springs along the vibration transmission body. The base is welded by steel coils. There are access doors and electrical switch seats on the bottom wall. An annular flange is welded on the upper part of the base wall, and the flange is connected with the vibration transmission body through a vibration isolation spring.

When the vibratory sifter is working, the eccentric masses with different phases at the upper and lower ends of the vibrating motor generate a composite inertial force due to the centrifugal effect of high-speed rotation, which forces the screen body to produce multi-rotation vibration, and its vibration trajectory is a complex three-dimensional space. curve. The projection of this curve on the plane is a circle, and the projection on the two vertical planes is an ellipse. Adjusting the phase angle of the eccentric blocks at the upper and lower ends of the vibrating motor can change the movement trajectory of the material on the screen surface, so that the screen body will produce flat-rotating vertical composite vibration, and the material will pass through the screens of different levels to achieve the purpose of classification operation .

Address:China,Yanjin county forest park gate to the west 1000 meters north road.