Vibratory separator is a commonly used screening equipment, widely used in dry and wet screening processes. Vibratory separator separates raw materials according to different particle sizes through the action of vibration force and screen. This article will introduce the vibratory separator for dry and wet sieving, discuss their working principles and practical applications in different fields.

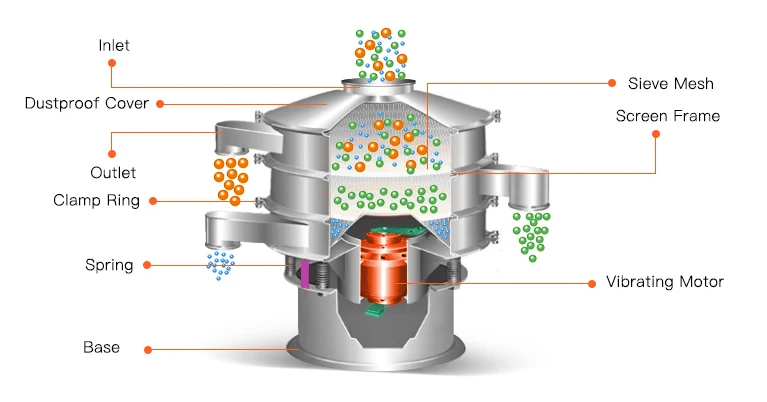

The vibratory separator uses vibration force to vibrate the raw materials on the screen surface, thereby screening the raw materials. Here's how it works:

Dry screening: In dry screening, after the raw materials enter the vibratory separator, the raw materials move quickly on the screen surface through the action of vibratory force. Smaller particles will fall through the sieve holes into the collector below, while larger particles cannot pass through the sieve holes and are left on the screen surface. By adjusting the strength of the vibration force and the size of the sieve holes, raw materials of different particle sizes can be screened.

Wet screening: In wet screening, the raw materials are mixed with water or other liquids and then enter a vibratory separator. The vibration force shakes the mixture rapidly on the screen surface, causing the solid particles to separate from the liquid. Smaller solid particles pass through the sieve holes into the collector below, while the liquid flows out through the sieve holes. By controlling the vibration force and the size of the screen holes, wet screening of solid particles of different sizes can be achieved.

Vibratory separators are widely used in various industries, including but not limited to the following areas:

Mining and metallurgy: Vibratory separators can be used for screening and classifying ores to classify ores according to different particle sizes. In metallurgical processes, it can be used for solid-liquid separation and wastewater treatment.

Construction and building materials: Vibratory separators can be used for screening and grading construction materials, including sand, gravel, cement, etc. It plays an important role in concrete production, roadbed construction and construction projects.

Chemical industry and food: Vibratory separators can be used for screening and classifying chemical raw materials and food raw materials. It can ensure the quality and consistency of raw materials and improve product production efficiency.

Waste treatment: Vibratory separators have important applications in waste treatment. It can be used for screening and classifying waste to achieve resource utilization and environmental protection of waste.

As a commonly used screening equipment, vibratory separator plays an important role in dry and wet screening processes. It realizes the separation and classification of raw materials through the action of vibratory force and screen. Vibratory separators for dry and wet sieving have the advantages of efficient screening, precise classification and flexible adaptability, and are widely used in mining, construction, chemical industry, waste treatment and other fields. With the development of industry and advancement of technology, vibratory separator for dry and wet sieving will continue to play an important role and contribute to the improvement of production efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.