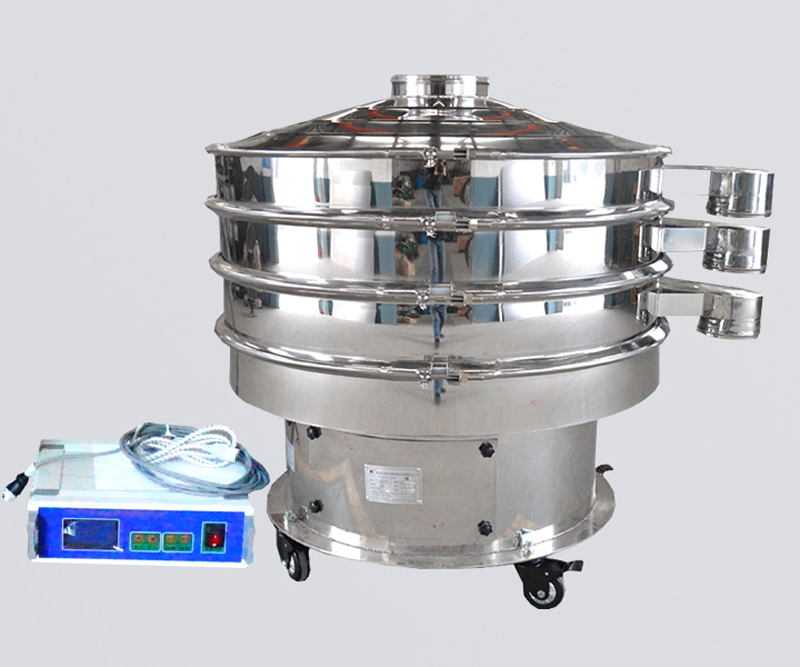

Mobile vibrating screen is a flexible and portable screening equipment with a wide range of applications. Its convenient mobility and efficient screening capabilities allow it to play an important role in multiple industries. So specifically what is Mobile Vibrating Screen used for?This article will introduce the multi-functional application of mobile vibrating screens, demonstrating their value and advantages in construction, mining, metallurgy, chemical industry and waste treatment.

Sand and gravel screening: Mobile vibrating screens can be used to screen construction sand and gravel to remove impurities and unwanted particles to ensure the quality and uniformity of sand and gravel. It can be used in areas such as concrete manufacturing, road construction and construction projects.

Gravel Grading: In construction projects, gravel needs to be graded to meet the needs of different uses. The mobile vibrating screen can adjust the screening parameters as needed to separate gravel into different particle size classes for the production of construction materials such as concrete, asphalt and roadbed.

Construction waste treatment: Construction sites generate a large amount of waste, such as concrete fragments, brick and tile residues, etc. Mobile vibrating screens can be used to screen and classify construction waste, separate recyclables and useful substances, and achieve resource utilization and environmental protection of waste.

Ore screening: Mobile vibrating screens play an important role in the mining industry. It can screen and classify ores, classify ores according to different particle sizes, separate the required ore particles, and improve the utilization rate and production efficiency of ores.

Coal screening: In the coal industry, mobile vibrating screens are used to screen and classify coal. It can classify coal according to different particle sizes, remove impurities and unqualified particles, and improve the quality and market competitiveness of coal.

Mobile vibrating screens are also widely used in the metallurgical industry. It can screen metallurgical raw materials, remove impurities and unqualified particles, and ensure the quality and stability of the metallurgical process. At the same time, it can also be used for waste treatment and recycling, improving resource utilization and environmental protection benefits.

Many production processes in the chemical industry require screening and grading of raw materials. Mobile vibrating screens can be used to screen chemical raw materials to ensure the quality and consistency of raw materials and improve the production efficiency of chemical products. In addition, it can also be used for solid-liquid separation in chemical wastewater treatment to reduce wastewater discharge and environmental pollution.

Mobile vibrating screens play an important role in waste treatment. It can be used to screen and sort waste, separating recyclables, useful materials and garbage. Through screening and grading, waste resources can be utilized, reducing dependence on natural resources, while also reducing the impact of landfill and incineration on the environment.

As a flexible and portable screening equipment, mobile vibrating screen has multi-functional applications in the fields of construction, mining, metallurgy, chemical industry and waste treatment. It can be used for sand and gravel screening, gravel classification, ore screening, waste treatment and other tasks, providing efficient and convenient screening solutions for these industries. With the development of industry and the improvement of environmental protection awareness, mobile vibrating screens will be used more and more widely in various fields, making greater contributions to the improvement of production efficiency and the sustainable utilization of resources.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.