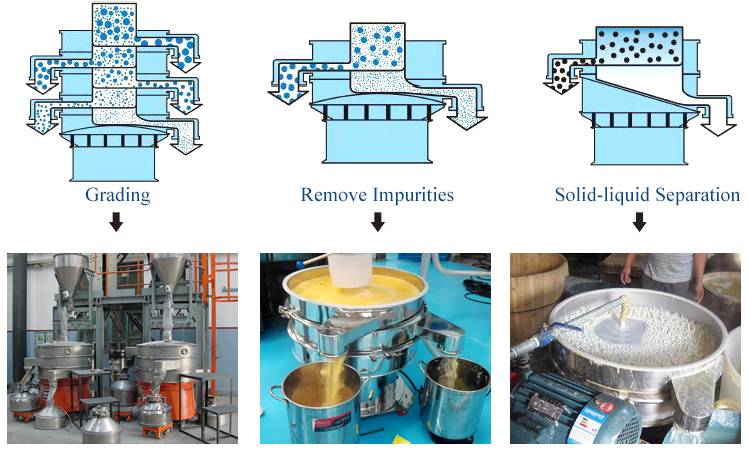

Vibrator separation sieve is used to effectively separate oversized contaminants, fines or solids from powder, granule or slurry mixtures, the largest particles/parts are removed from the separator on the top sieve deck, the finest particles are removed from It is removed from the lowest screen cloth at the bottom, and can divide the product into 2-5 different sizes in one operation, it is suitable for sieving from 30mm to 25 microns.

Vibrator separation sieve uses YZUL vertical vibration motor as the power source. When the rotary vibrating screen is working, the exciter shaft rotates at a high speed, and the eccentric bodies at both ends form a consistent force. The movement trajectory is a three-dimensional curve in space. The projection of this curve on the horizontal plane is a circle, and the projection on the two vertical planes is an ellipse. Adjusting the angle between the two eccentric bodies can change the flow mode of the material on the screen surface to achieve different screens.

1. Suitable for dry or liquid products, according to the mesh size, the required particle size can be from 30 mm to 25 microns.

2. By increasing the number of screen layers, the products can be screened with different fineness, and at most 5 kinds of products of different specifications can be screened at the same time.

3. 360-degree automatic discharge, the discharge port can move freely along the circumferential direction, the discharge is convenient, and it is suitable for various production lines.

4. The overall sealing performance is good. Except for the dust caused by feeding and receiving materials, the amount of dust generated by the equipment itself is very small.

5. Different performances can be changed according to the use site and use space, and different mechanical and powerless auxiliary screening can be added at the same time, such as adding dust removal ports, iron removers, cleaners, airtight structure screening, or adding vacuum feeders, etc. , Ultrafine powder screening can increase the ultrasonic screening system.

Separate large particles in powder

Separate the residue in soy milk

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

We understand your need to produce contamination-free products; that's why these sieves are quick and easy to clean. All components are easily accessible and can be cleaned quickly to minimize time between production runs.

1. Ball cleaning system: The bouncing ball net cleaning device is the most common net cleaning device. Its shape is round, and the material can be divided into two types: rubber material and silicone material. Its working principle is that it is evenly distributed on the pallet, generally 5-8 within ten centimeters. When the screen is vibrating and sieving, the bouncing ball also jumps and hits the screen, so as to achieve the purpose of cleaning the screen. The most common type of bouncing ball cleaning device is a three-dimensional rotary vibrating screen (also installed in a linear vibrating screen of a wooden mesh frame).

2. Brush cleaning system: The brush device is composed of two sets of cylindrical silica gel (the number is related to the diameter of the screen frame). The rotating brush is installed in the center of the screen frame, and the machine vibration is used to continuously rotate and remove any accumulations on the screen.

3. Ultrasonic cleaning system: This device uses ultrasonic vibration waves to clean the screen. The conventional electricity is converted into 18KHZ high-frequency electricity through the ultrasonic power supply, and the transducer acts on the grid to solve the cleaning and screening of high-fine materials.

Vibrator separation sieve can dehydrate the solid-liquid mixture and remove impurities in the liquid. It is generally used in juice, dairy, ceramic slurry, glaze filtration, Chinese and Western medicine liquid extraction, paint filtration, automobile glue filtration, waste water recovery, etc. And other industries.

Vibrator separation is suitable for sieving wet and dry materials, and can remove oversize and contaminants to improve product quality. These industrial screening machines are used for a variety of applications, including screening pharmaceutical powders, various food powders and powder coatings. They are also available in different sizes and options to meet your screening requirements.

Xinxiang Dahan vibrator separation sieve mainly produces vibrator separation sieve, ultrasonic vibrator separation sieve, 2-500 mesh aperture, can be used at the same time with 1-5 layers according to different needs of customers, carbon steel, 304 stainless steel and plastic materials and other models are complete , mainly used for dry and wet screening and grading of powder, granule or slurry, and can also be customized according to customer requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.