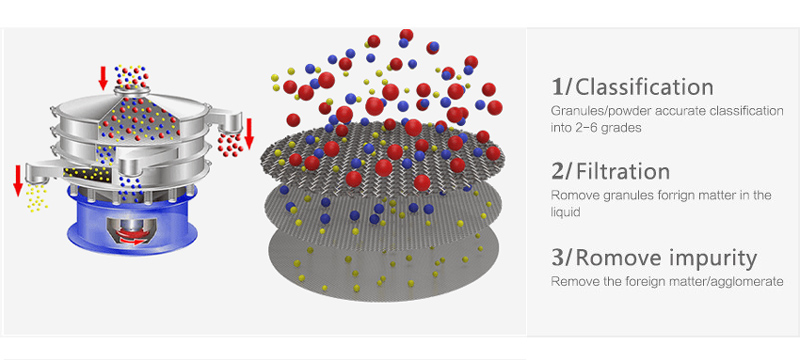

Can be used to screen dry powder or granular products as well as wet products and liquids, separating products into 2-5 different sizes

![]()

![]()

Price::$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

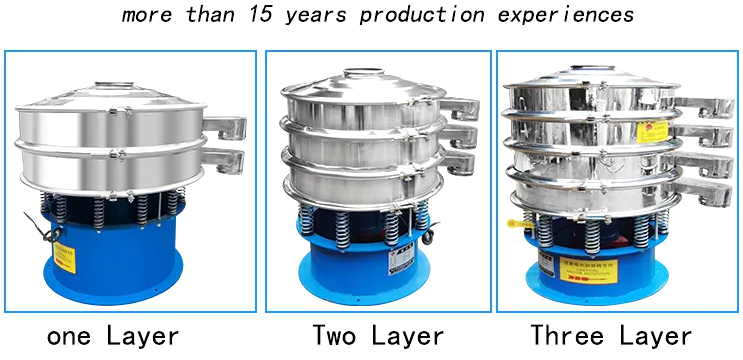

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Motor power: 0.25-3kw

Application: Used to separate oversized particles and foreign matter from products, as well as solid-liquid separation of liquids, fineness control of suspended particles, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Vibratory separator is a device that uses vibration to separate and classify materials according to their particle size and shape, and is often used in industries such as food, pharmaceutical, chemical and cosmetics to remove impurities or separate different types of materials. The equipment usually consists of a shaker or sieve placed in an inclined position. The material to be separated is conveyed onto the screen, and vibrations cause the particles to move and separate according to size and shape. Smaller particles pass through the screen and are collected in a container, while larger particles remain on the screen and are discharged at the end of the process.

Vibratory separators can be designed with different types of screens, including wire mesh, nylon mesh and perforated plates, depending on the application and desired particle size range. They can also be equipped with various features such as adjustable vibration intensity, multiple decks and different discharge options.

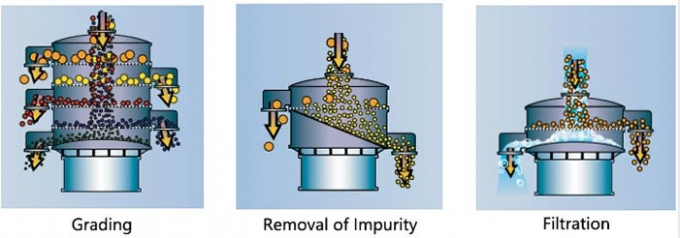

The main function of a vibratory separator is to separate and classify materials based on their particle size and shape. This is achieved through the use of vibrations, which cause the particles to move and separate according to their size and shape. The device is designed to remove impurities or separate different types of materials.

1. Removal of impurities: often a 1-layer sieve, usually fine products that pass through the sieve are retained as good products, and can also be used to remove broken or undersized products. In most production environments, inspection screens are either the first machine in the process to prevent contamination or the last machine before packaging machines for final quality checks.

2. Classification: Accurate separation of particles of different sizes from the product so that the final material can be classified into different sizes. Due to the particle size being very close to the aperture size, the throughput of classifying screens is usually much slower than that of trash screens, however, this can be compensated by a larger mesh area or fine-tuning the motor weight setting.

3. Solid-liquid separation: it can quickly remove insoluble matter in various slurries. It can filter up to 100 cubic meters per hour, and is suitable for filtering liquids such as ceramic glazes, pigments, soybean milk, and fruit juices.

Vibrating Screen Separator

Ideal for sieving, classifying, grading or peeling powders and liquids. By using multiple screens, material can be graded and sorted into five or fewer sections of varying sizes. Our innovative vibratory separator is a proven solution for a range of industries including pharmaceuticals, chemicals, food and beverage, delivering up to 70% higher throughput compared to other traditional separators.

Ultrasonic Vibrating Screen

It is suitable for industrial screening of mass production. It can be used for safe screening of foreign matter, separation of solids in liquids, separation of different particle sizes in the same product, etc. It is equipped with an ultrasonic deblinding system, suitable for high viscosity and high static electricity For fine powder, the screening accuracy can be increased by more than 80%, and the output can be increased by 2-5 times.

450 Filter Sieve

It is suitable for industrial screening of mass production. It can be used for safe screening of foreign matter, separation of solids in liquids, separation of different particle sizes in the same product, etc. It is equipped with an ultrasonic deblinding system, suitable for high viscosity and high static electricity For fine powder, the screening accuracy can be increased by more than 80%, and the output can be increased by 2-5 times.

When the vibratory separator is working, the eccentric masses with different phases at the upper and lower ends of the vibrating motor generate a composite inertial force due to the centrifugal effect of high-speed rotation, which forces the screen body to produce multi-rotating vibration, and its vibration trajectory is a complex three-dimensional space. curve. The projection of this curve on the plane is a circle, and the projection on the two vertical planes is an ellipse. Adjusting the phase angle of the eccentric blocks at the upper and lower ends of the vibrating motor can change the movement trajectory of the material on the screen surface, so that the screen body produces horizontal-rotating vertical composite vibration, and the material passes through the screens of different levels to achieve the purpose of grading operations. .

Improve manufacturing efficiency

Screen and grade material into up to five sized fractions at once

Improve product quality

Material flows over up to four mesh screens for accurate grading and separation

Improve throughput

Impurities and coarse materials are automatically discharged, continuous operation is possible, and the output can reach 5 tons/hour

No dust

There are dust-proof strips and tie rings between each layer of screen frames of the equipment, which can ensure the complete sealing of the equipment and reduce the friction between the screen frames.

Not easy to block

Bouncing and cleaning devices are installed under the screens of each layer, which can effectively avoid the problem of material blocking the screen by continuously hitting the screens.

Long lasting

The sub-network structure is adopted to ensure the flatness and tension of the screen to prevent the impact of materials from collapsing the working net.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibratory separators are used in a wide range of industries and applications, including:

1. Food and beverage industry: used to remove impurities in grains and other foods, such as stones. They are also used to separate different types of food such as nuts, fruit and grains by size and shape.

2. Pharmaceutical industry: used for grading and separating medicinal powder and tablets according to size and shape. They are also used in the production of capsules and other pharmaceutical products.

3. Chemical industry: used to separate and classify chemicals according to particle size and shape. They are also used in the production of pigments, plastics and other chemical products.

4. Cosmetics industry: used to remove impurities and separate different types of cosmetics such as powders, creams and lotions according to particle size and shape.

5. Recycling industry: used to separate and sort recyclable materials such as plastic, metal and paper according to size and shape. They are also used to dispose of e-waste and other types of recyclable materials.

| Raw Material | Proportion | Mesh Size(mesh) | Model | Method | Capacity (kg/hr t/hr) |

| glucose powder | 0.8 | 6,20 | DH-1200-2S | Dry | 2000㎏ |

| wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 t |

| flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| rice flour | 0.5, 0.8 | 100 | DH-1000-1S | Dry | 300 ㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 t |

| salt | 1.2 | 30,80 | DH-1500-1S | Dry | 5000㎏ |

| pollen | 0.4 | 12 | DH-1500-1S | Dry | 100㎏ |

| waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000t |

| dyeing and steaming wastewater | 1 | 150 | DH-1000-1S | Wet | 22000t |

| waste oil | 0.9 | 100 | DH-1000-1S | Wet | 3800t |

| epoxy resin | 1.8 | 100 | DH-1000-1S | Dry | 280㎏ |

| graphite | 1.2 | 16,40,80 | DH-1000-3S | Dry | 1400㎏ |

| lead powder | 11.34 | 10,80 | DH-1000-2S | Dry | 1000㎏ |

| plaster | 1.5 | 100 | DH-1200-1S | Wet | 18000 t |

| mud | 1.1 | 100 | DH-1000-1S | Wet | 10000 t |

| Kaolin | 0.4 | 100 | DH-1000-1S | Dry | 200㎏ |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.